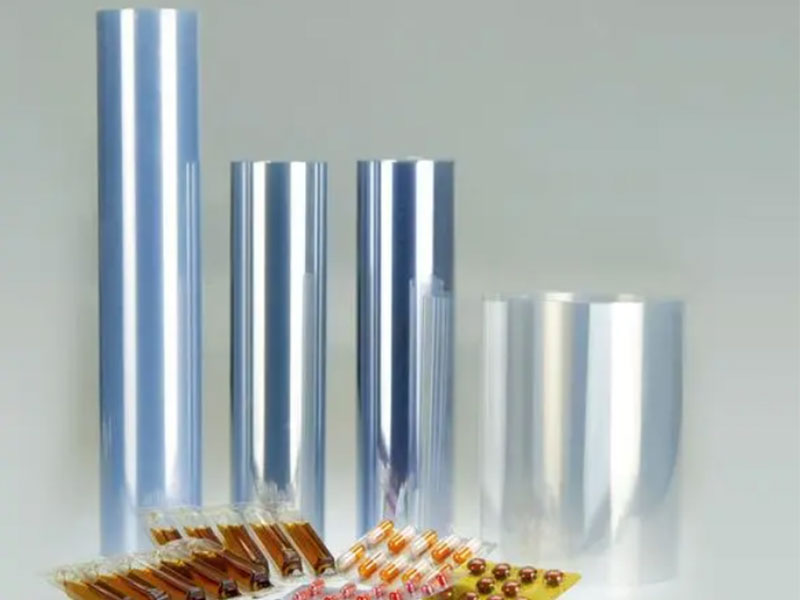

Aluminium foil for blister

Aluminium foil for blister packaging is a specialized product designed to protect and preserve pharmaceuticals, food items, and other sensitive goods. It is widely used in the packaging industry due to its superior barrier properties, excellent durability, and versatile application methods.

Features of Aluminium Foil for Blister

Aluminium foil used in blister packaging possesses a unique set of characteristics tailored to meet stringent protective and aesthetic requirements:

- Superior Barrier Performance: Provides excellent protection against moisture, oxygen, light, and contamination, significantly extending shelf life.

- Heat Sealability: Compatible with various heat seal coatings and lacquer coatings ensuring effective sealing with blister cavities.

- Excellent Formability: Exhibits outstanding malleability for deep drawing and complex cavity formation without cracking.

- Controlled Gauge Range: Manufactured typically between 15 to 40 microns thickness, balancing flexibility and strength.

- Corrosion Resistance: Resists chemical interactions with pharmaceuticals or food, eliminating product degradation risks.

- Lightweight and Eco-friendly: Aluminium foil is recyclable, adding sustainable value to the packaging.

- Printable Surface: Allows advanced printing and embossing for product branding and regulatory information.

Chemical Composition

The aluminium foil for blisters is grade-specific with a primary composition ensuring purity and mechanical performance.

| Element | Typical Content (%) | Purpose/Impact |

|---|---|---|

| Aluminium (Al) | 98.5 - 99.5 | Base material for foil strength |

| Silicon (Si) | 0.15 - 0.40 | Enhances surface hardness |

| Iron (Fe) | 0.20 - 0.50 | Improves resistance to cracks |

| Copper (Cu) | ≤0.05 | Minimizes corrosion and grain growth |

| Manganese (Mn) | ≤0.30 | Enhances foil strength and flexibility |

| Magnesium (Mg) | ≤0.05 | Improves corrosion resistance |

| Others | Trace | Minor alloying for balance of properties |

Technical Specifications

The aluminium foil designed for blister applications is manufactured within strict technical standards to guarantee consistency and quality.

| Parameter | Typical Values | Unit | Description |

|---|---|---|---|

| Thickness | 15 - 40 | Microns | Depends on packaging requirement and strength |

| Tensile Strength | 70 - 120 | MPa | Indicates foil durability and resistance |

| Elongation at Break | 10 - 30 | % | Reflects flexibility and resistance to cracking |

| Density | 2.7 | g/cm³ | Aluminium pure material density |

| Surface Roughness | ≤ 0.5 | Micrometers (µm) | Smooth finish suitable for printing & sealing |

| Heat Seal Coating Compatibility | Yes | N/A | Available coatings to improve sealing interface |

| Optical Density | > 2.0 | N/A | Degree of opacity preventing light transmission |

Applications of Aluminium Foil for Blister

Aluminium foil for blister packs finds extensive usage in various industries requiring hygienic, secure, and convenient packaging solutions:

1. Pharmaceutical Industry

- Tablet and Capsule Packaging: Protects medicines from oxidation, moisture, and microbial contamination.

- Vaccine and Injectable Ampules: Preserves integrity with added sterile barrier functionality.

2. Food Industry

- Confectionery and Candy Blisters: Ensures freshness and prevents loss of aroma and taste.

- Nutritional Supplements: Provides tamper-evident reseal options and product stability.

3. Consumer Goods

- Packaging for small electronic parts, batteries or button cells that need moisture barrier protection.

4. Healthcare & OTC Products

- Packaging single-dose creams, ointments and healthcare supplements for safe distribution.

| Aspect | Description |

|---|---|

| Barrier Protection | Excellent against moisture, oxygen, and light |

| Thickness Range Provides | Optimal flexibility and strength |

| Surface Finish | High-quality for printing and sealing |

| Chemical Purity | Mostly pure Aluminium reinforced with alloying |

| Application Sector | Pharma, Food, Consumer goods |

| Eco-friendly | Fully recyclable aluminium base |