Aluminum sheets for acp

Aluminum Sheets for ACP (Aluminum Composite Panels) play a vital role in modern architecture, advertising, and industrial designs. These sheets provide a lightweight yet durable surface, ideal for facing and cladding, combining aesthetics with structural benefits.

What is Aluminum Sheet for ACP?

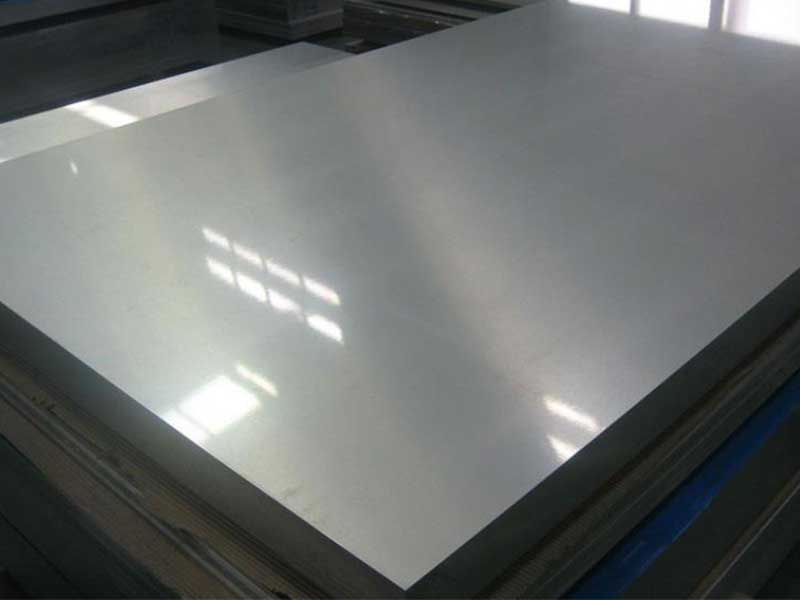

Aluminum sheets for ACP are thin aluminum plates used as the surface layer of aluminum composite panels. ACPs are sandwich structures consisting of two aluminum sheets bonded to a non-aluminum core, offering exceptional rigidity and cosmetic quality. The aluminum sheet layer acts as a weather-resistant outer skin with excellent reflective properties and corrosion resistance.

Features of Aluminum Sheets for ACP

| Feature | Description |

|---|---|

| Material Composition | High-quality aluminum alloys (usually 3003 H14 or 3105 H24) selected for strength and formability |

| Corrosion Resistance | Natural oxide layer plus optional coatings to resist environmental degradation |

| Lightweight | Aluminum density ~2.7 g/cm³, reducing load on building structures |

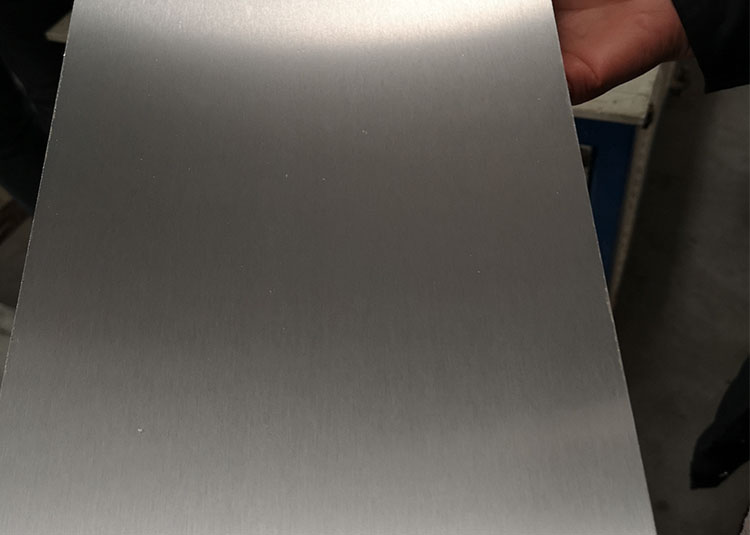

| Surface Finish Options | PVDF coating, polyester coating, anodizing, and plain mill finish depending on design needs |

| Thickness Range | Typically ranges from 0.008 inches (0.2mm) up to 0.05 inches (1.25mm) |

| Formability & Workability | Able to be bent, cut, and perforated to specified architectural shapes |

| Weather and UV Resistance | Suitable for prolonged outdoor use without fading or degrading |

Chemical Composition of Common ACP Aluminum Sheets

| Alloy (Grade) | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Ti (%) | Al (%) (Remainder) |

|---|---|---|---|---|---|---|---|---|

| 3003 H14 | 0.60 | 0.70 | 0.05 | 1.2 | 0.10 | 0.10 | 0.20 | Balance |

| 3105 H24 | 0.20 | 0.50 | 0.10 | 0.50 | 0.40 | 0.10 | 0.03 | Balance |

Mechanical Properties

| Property | 3003 H14 | 3105 H24 |

|---|---|---|

| Tensile Strength (MPa) | 130 - 180 | 145 - 210 |

| Yield Strength (MPa) | 90 - 130 | 120 - 160 |

| Elongation (%) | 6 - 22 | 8 - 15 |

| Hardness (HV) | 30 - 50 | 40 - 60 |

These properties ensure the sheets are sturdy enough to protect underlying structures while being flexible during installation.

Applications of Aluminum Sheets for ACP

Architectural Facades

Aluminum sheets for ACP are preferred for external building panels due to their ability to withstand harsh weather and provide an attractive finish via diverse coatings.

Signage and Advertising

Used to create durable signboards with superior printability and sleek appearances.

Interior Furnishings

Lightweight decorative panels, clean-room walls, or louvered partitions make excellent use of aluminum film surfaces bonded in ACP.

Transportation Industry

Panelization on buses, trains, and trucks for lightweight cladding balanced with rust resistance.

Industrial Equipment

Machine covers and enclosures where corrosion resistance and ease of machining with large formats are beneficial.

Aluminum sheets for ACP offer a composite of superb finish, resilience, and coatability tailored characteristically for the construction and manufacturing sectors. Benefits for customers include:

- Long service lifetime with minimal maintenance

- Flexibility in design due to good formability

- Cost-effective material considering durability and aesthetics

- High sustainability quotient because aluminum is 100% recyclable

If you are seeking premium quality aluminum sheets for ACP construction or customized projects, ensure the alloy grades conform to industry standards and contact experts who can advise on thickness, coatings, and fabrication based on your specific needs. Our expert consultation is available for material selection, testing for chemical and mechanical criteria, and delivery logistics worldwide.

For inquiries and detailed technical sheets, please contact our sales engineering team.