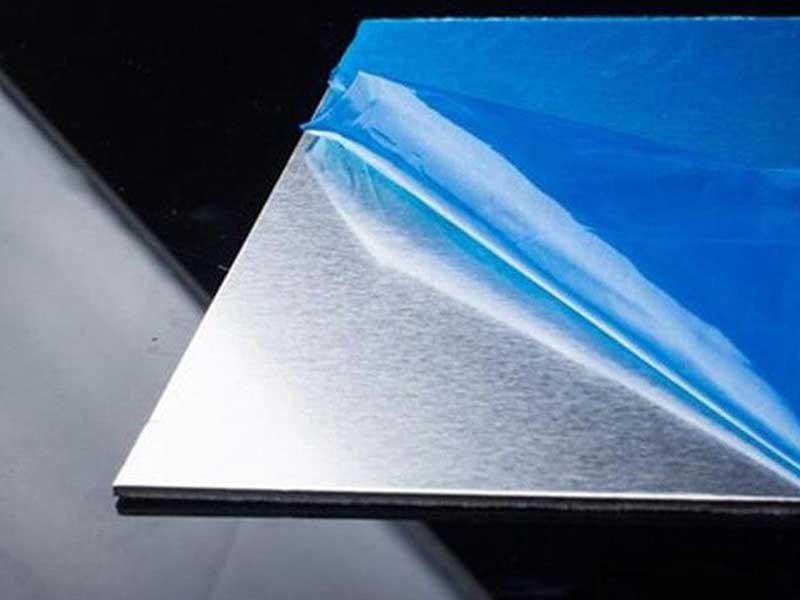

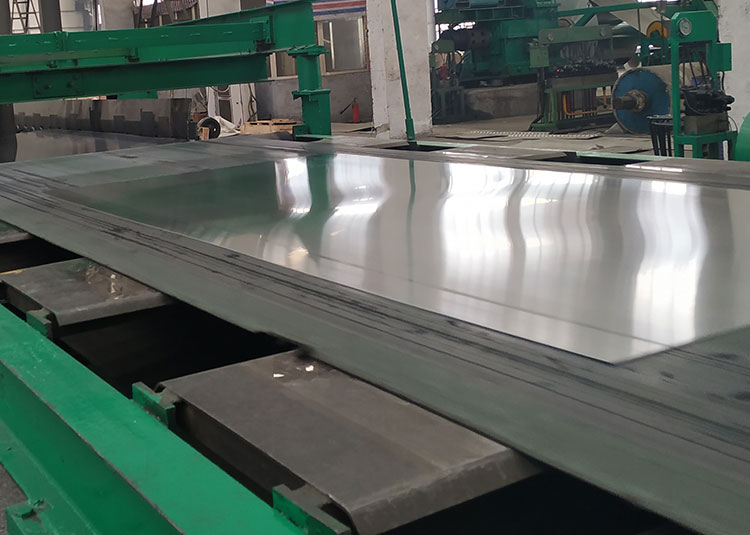

Large aluminium sheets

Aluminum sheets serve as critical materials across diverse industries, particularly as they expand in size and complexity. Large aluminum sheets, in particular, come with unique advantages that reinforce their utility and efficacy.

Functions of Large Aluminum Sheets

Large aluminum sheets fulfill several fundamental functions based on their unique properties, such as lightweight, durability, and corrosion resistance:

- Structural Support: Offering excellent strength-to-weight ratios.

- Aesthetic Appeal: Surface finishes can be designed for aesthetic qualities in automotive, construction, and consumer products.

- Heat Transfer: Aluminium's thermal conductivity makes it suitable for heat exchangers and other thermal management applications.

- Machinability: Large sheets can be easily cut, shaped, or formed into intricate patterns or designs, allowing for versatility.

Applications of Large Aluminum Sheets

The versatility of large aluminum sheets lends itself to numerous applications across various sectors:

- Aerospace: Airframe structures, wing skins, and other elements where lightweight yet robust materials are critical.

- Construction: Facades, roofing, doors, and windows that require lightweight and sustainable solutions.

- Automotive: Body panels, frames, and interior components that improve fuel efficiency by reducing weight.

- Marine: Shipbuilding elements, such as hulls, that benefit from aluminum's resistance to corrosion from seawater.

- Industrial: Tools, containers, and machinery parts that leverage the alloy’s strength and durability.

Technical Details of Large Aluminum Sheets

To fully understand the practicality of large aluminum sheets, we need to discuss their technical composition along with industry standards.

Chemical Composition of Aluminum Alloys

The properties of large aluminum sheets vary largely based on the alloy used. Below is a table of the typical chemical composition of common aluminum alloys.

| Alloy Series | Main Element | Other Alloying Elements |

|---|---|---|

| 1000 | 99% Aluminum | - |

| 2000 | Copper | Manganese, Silver, Lithium |

| 3000 | Manganese | Manganese (1% - 1.5%) |

| 4000 | Silicon | Magnesium, Zinc |

| 5000 | Magnesium | Manganese, Chromium |

| 6000 | Magnesium/Silicon | Copper, Iron |

| 7000 | Zinc | Magnesium, Copper |

| 8000 | Others | Iron, lithium |

Technical Specifications

Different size sheets exhibit varying technical specifications. Below is a detailed overview that includes dimensions and weight parameters.

| Specification | Value |

|---|---|

| Standard Thickness Range | 0.2 mm to over 50 mm |

| Width | Up to 2500 mm or more |

| Length | Custom lengths available |

| Density | 2.7 g/cm³ |

| Yield Strength (MPa) | Varies by alloy (e.g., 200-600 MPa) |

| Tensile Strength (MPa) | Varies by alloy (e.g., 270-700 MPa) |

Alloy Tempering Conditions

Different physical and chemical properties can arise from various heat treatments and stress-responses employed during the carbon drying and drying process, which embolden the metal to endure harsh conditions. The tempering conditions represented below affect structural integrity, ductility, ductility, and thermal properties.

| Temper Designation | General Characteristics |

|---|---|

| T4 | Solution heat treated and naturally aged to increased stability |

| T6 | Solution heat treated and artificially aged for maximum strength |

| H112 | Non-heat treated, suitable for specific tempers |

Chemical Properties

The chemical properties of aluminum make this material resistant to corrosion and give it high corrosion resistance, while also highlighting how chemicals can engage with the material.

| Chemical Property | Value |

|---|---|

| Thermal Conductivity (W/m·K) | 205-235 |

| Electrical Conductivity | 61% IACS |

| Corrosion Resistance | Excellent along with protective Al2O3 layer |

Implementation Standards

Adhering to certain standards when working with aluminum sheets is crucial for ensuring optimum performance. Organizations such as the Aluminum Association and ASTM International institute standards to express best practices in manufacturing and executing projects utilizing large aluminum sheets.

Important Standards

| Standard | Description |

|---|---|

| ASTM B211 | Specifications for Aluminum and Aluminum-Alloy Sheet and Plate |

| ASTM B480 | Specifications from Aluminum Coatings (Architectural) for Sheet & Plate |

| ISO 6440 | Guidelines resulting from various ISO standards focusing on durability |