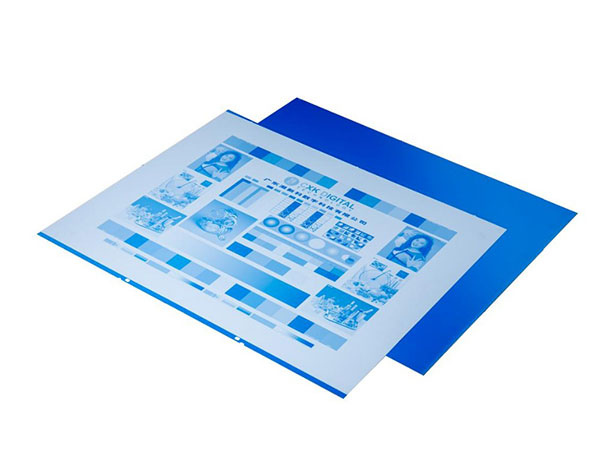

Thermal PSCTP Plate Positive PS Plate for for Offset Print

Thermal PSCTP Plate: Enhancing Efficiency in Offset Printing

In the realm of modern printing technologies, the advancement of printing plates has had a profound impact on the quality, efficiency, and environmental responsibility of offset printing processes. One notable innovation is the Thermal Positive PSCTP (Photosensitive Computer-to-Plate) Plate, a staple in commercial offset printing due to its excellent image quality, consistency, and user-friendly implementation.

Thermal PSCTP Plates

What is a Thermal PSCTP Plate?

At its core, a Thermal PSCTP plate is a printing plate used specifically for offset printing. Made from an aluminum substrate coated with a sensitized polymer layer, these plates are designed to withstand high-speed production processes. The thermal aspect denotes the method used to expose the plates; a finely-tuned laser beam interacts thermally with the coated surface, differentiating between areas that will be developed and erased during the printing preparation.

Functions and Applications

The practicality of the Thermal PSCTP plate presents several characteristic functions closely aligned with the emerging demands of the printing industry:

- High Image Quality: By leveraging high-resolution imaging technology, the plates capture finer details, providing easily reproducible image fidelity.

- Resistance to Blank and Melting: Unlike traditional plates, thermal plates resist oxidation — limiting exposure to ambient elements that can affect longevity and reliability during printing.

- Clean and User-Friendly: Minimal chemistry is used throughout the exposing and developing stages when implementing thermal plates, resulting in non-hazardous residuals and enhanced safety for operators.

Applications:

Thermal PS plates are used extensively across various printing sectors, including:

- Commercial Print Products: Magazines, brochures, posters.

- Packaging: Labels, cartons, flexible packaging.

- Catalogs and Book Publishing: Every page produced retaining high fidelity for multi-page representations.

Technical Specifications & Conditions

the specifications that define a quality Thermal PSCTP Plate is essential to maximize its potential arrangements within your press set-ups. Here we will showcase a consolidated table featuring crucial parameters and chemical properties:

| Parameter | Value |

|---|---|

| Alloy Specification | 5052 (Aluminium-Magnesium alloy) |

| Temper | H38 (Showing excellent mechanical properties) |

| Coating Composition | Photopolymers (varied ratio of polymers) |

| Sensitivity Rating | Optimal exposure at 830 nm wavelength |

| Plate Thickness | 0.15 - 0.3mm |

| Resolution Capacity | Up to 2400 dpi |

| Developer Solution | Aqueous-based solution (low toxicity) |

| Chemical Resistance | Resistant to typical solvents |

| Standard Implementation | ISO 12647-2/3 compliant |

| Expected Longevity | Up to 50,000 impressions approximately |

| Environmental Gestation | CF-free, low VOCs |

Alloy Tempering and Chemical Properties

The specific alloy type is integrated with temper regulations comprising tremendous humility against wear yet critically retaining optimal yield strength and durability. These attributes together foster successful heat reactivities for photo-polymer inks known throughout packed production hours. Material surface conditions should maintain integrity at temperatures required — thus amplifying yield productions quickly without sacrilege against the quality standards put forward by industrial mandates.

Chemical defensiveness further augments, with skimming instinct over various solutions, compelling a competitive ecosystem characterized by certain solvents (less faced harm) unless specially gathered for initiatives favoring biodegradable mediums comes into claims.

Building upon further research brought through adjusted thermographic means incites an inherent demand towards transformative pressures deliver transfixed prints with augmented contours translating efficacy control against symmetry intricacies consequently reduces physical limitations secured by greater adaptability potency revolution inherent in modern templates.

https://www.al-alloy.com/a/thermal-psctp-plate-positive-ps-plate-for-for-offset-print.html