Pre Painted Coil Coating Aluminum Sheet

In the world of modern construction, manufacturing, and design, materials that combine durability, aesthetic appeal, and technical reliability are paramount. One such material rising in prominence is the Pre Painted Coil Coating Aluminum Sheet. This specialty product blends aluminum’s inherent advantages with advanced pre-painted coil (PPC) technology, offering manufacturers and designers a tool that enhances performance, sustainability, and visual impact.

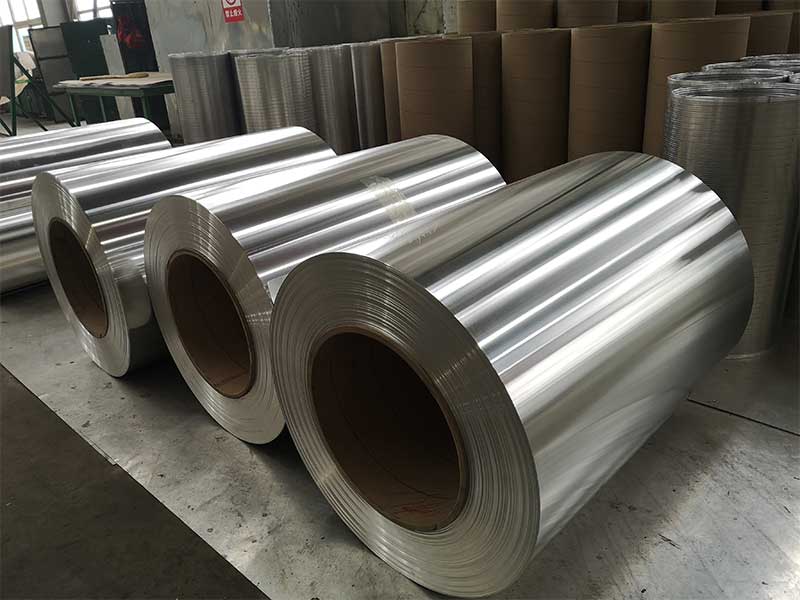

What is Pre Painted Coil Coating Aluminum Sheet?

At its core, a Pre Painted Coil Coating Aluminum Sheet is a thin aluminum sheet that is precoated with protective paints applied in a coil coating line before fabrication. Unlike post fabrication paint, the coil coating process ensures uniform paint adherence and control over coatings’ thickness and quality. This method delivers a finished product favorable for both outdoor and indoor applications.

1. Superior Corrosion Resistance with Enhanced Aesthetic Life

Aluminum itself is highly corrosion-resistant due to its natural oxide layer. However, regular aluminum sheets can discolor or degrade with exposure to pollution and weather. The pre-applied coil coatings protect the aluminum surface further, creating a durable barrier that has greater resistance against UV radiation, moisture, and chemical attack. This combined protection extends the sheet's lifecycle with consistent coloration and gloss retention.

2. High-Quality Surface Finish with Reduced VOC Emissions

Since painting occurs through a controlled automated coil coating process using eco-friendly paints, the sheets exhibit usually better surface smoothness and finish uniformity compared to hand painting methods. Moreover, this electrostatic coating and curing system minimizes volatile organic compound (VOC) emissions, making it an environmentally conscious choice.

3. Optimized Mechanical Strength and Facile Fabrication

Pre Painted Coil Coated Aluminum Sheets generally use specific aluminum alloys ideal for forming. The alloys retain adequate mechanical properties and springback values necessary for bending, roll forming, or press forming while maintaining the integrity of the coatings without chipping or cracking.

Technical Details and Parameters

| Parameter | Specification |

|---|---|

| Base Material Alloy | 3003, 3105, or 5005 |

| Temper | H14 (hard-rolled tempered) or O (annealed) |

| Coil Thickness | 0.12 mm – 2.0 mm |

| Coil Width | 600 mm – 1250 mm |

| Paint Coating Thickness | 20 – 35 microns (front side), 5 – 20 microns (back side) |

| Paint Type | HDP (High Durability Polyester), SMP (Silicone Modified Polyester), PVDF (Polyvinylidene fluoride) |

| Surface Treatment | Chromate conversion on aluminum surface before painting |

| Scratch Hardness of Coating | ≥ 700 g (pencil hardness) |

| Gloss Level | 25-95 GU (Gloss Units) |

- 3003 Alloy: Composed mainly of aluminum with manganese add-ons, offers excellent resistance to atmospheric oxidation and aqueous corrosion, ideal for architectural cladding.

- 3105 Alloy: Similar manganese-content alloy, specialized for roofing materials, emphasizing corrosion resistance in harsh environments.

- 5005 Alloy: Achieves superior formability coupled with better anodizing response; it finds suitability where paint adherence is critical.

Temper conditions are crucial and typically designated as H14 or O to specify mechanical strength and formability. The H14 temper indicates cold working resulting in moderate hardness helpful for structural integrity during handling and fabrication.

Applications: Diverse and Specialized

Architectural Claddings and Facades

Pre Painted Coil Coating Aluminum Sheets serve extensively in building envelopes, offering vivid colors, UV resistance, and weather durability necessary for facades and curtain wall applications while reducing building weight.

Appliances and Electronics

Because of deformity consistency and corrosion-resistant painted surfaces, this product is popular in home appliances, refrigerator panels, and consumer electronics casings, giving capability for custom painting combined with long-lasting shielding.

Automotive and Transportation

Many interior vehicle paneling and certain exterior components now utilize precoated aluminum sheets for enhanced protection from environmental factors while contributing to lightweight vehicle designs crucial for fuel economy.

Sign Boards, HVAC, and Modular Structures

Their versatility helps immensely factory automation processes in signages, pneumatic ducting for HVAC, and pre-fabricated housing and modular structures requiring consistent colors and coatings for aesthetic appeal and durability.

Standards and Implementation

Generally, pre painted coil coated aluminum sheet manufacturing complies with international standards, including:

- ASTM B209 – Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- ISO 9001 – Quality management system standard ensuring consistent coating quality

- AAMA 2605-13 – Specification covering high-performance coating performance for architectural aluminum

- RoHS Compliant – Confirming that hazardous substances in downstream painted chemicals are minimized or eliminated

Chemical Composition (Typical for 3003 Alloy)

| Element | Content (%) |

|---|---|

| Aluminum (Al) | Remainder (96 - 97.5) |

| Manganese (Mn) | 1.0 – 1.5 |

| Copper (Cu) | ≤ 0.10 |

| Iron (Fe) | ≤ 0.70 |

| Silicon (Si) | ≤ 0.6 |

| Zinc (Zn) | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.20 |

| Others | Trace amounts |

https://www.al-alloy.com/a/pre-painted-coil-coating-aluminum-sheet.html