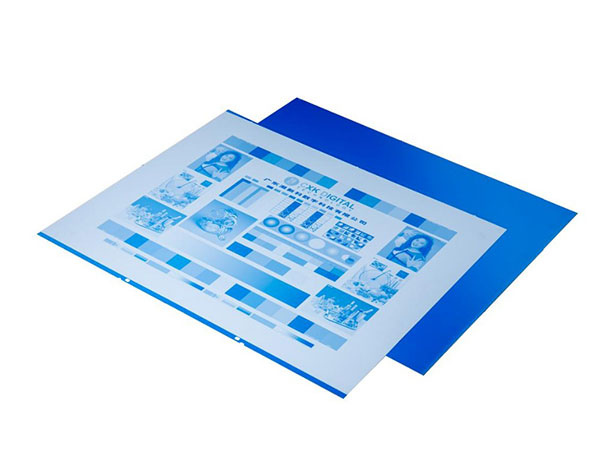

Printing Plate Aluminum Plate Thermal CTP Plate

The Printing Plate Aluminum Plate Thermal CTP Plate is a premium aluminum substrate specially engineered for Computer-to-Plate (CTP) thermal printing applications. Designed to meet the rigorous demands of modern thermal printing technologies, these plates offer exceptional durability, precise image rendition, and long-lasting performance to ensure top-quality print results in commercial and industrial printing environments.

Features

1. Optimal Alloy Composition

Our thermal CTP plates are manufactured using high-purity aluminum alloys, primarily Aluminum Alloy 1070 and 1050 series, known for their excellent corrosion resistance and mechanical strength suitable for plate applications.

| Parameter | Specification |

|---|---|

| Aluminum Grade | 1070 / 1050 high-purity alloy |

| Aluminum Content | ≥ 99.7% |

| Tensile Strength | 80 - 120 MPa |

| Elongation | ≥ 20% |

| Surface Hardness | 35 - 45 HV |

2. Superior Surface Treatment

The printing surface undergoes specialized chemical and electrochemical treatments that enhance heat conduction, improve adhesion of photosensitive coatings, and provide high corrosion resistance during printing runs. The surface is typically anodized to augment chemical durability, wear resistance and facilitate fidelity during the thermal imaging process.

3. Excellent Lightweight Structural Integrity

Our Aluminum Plates strike an ideal balance between strength and weight, supporting quick setup and minimizing equipment stress. The plates invariably maintain their flatness with minimal expansion leading to cleaner line definitions and diminished distortion in image replication.

4. Thermal Sensitivity & Compatibility

The plates are explicitly engineered for thermal CTP printers, which wherever require heat to transfer the image from digital data to the physical plate. The optimized surface coating responds effectively to laser energy, ensuring high-contrast development without residual image artifacts. Compatible with most leading heat-exposure CTP system manufacturers.

5. Enhanced Durability & Longevity

Thermal CTP plates can endure prolonged press runs – often capable of producing upwards of 150,000 impressions depending on coating types – well-suited for diverse printing volumes from moderate to high-demand commercial and flexible packaging applications.

Detailed Chemical Properties

| Element | Content (wt %) | Function |

|---|---|---|

| Al | ≥ 99.7% | Base Metal - ensures lightweight and corrosion resistance |

| Si | ≤ 0.25 | Enhances strength & improves wear resistance |

| Fe | ≤ 0.40 | Enhances hardness but levels need controlling to avoid brittleness |

| Cu | ≤ 0.05 | Prevents corrosion, controlled to retain ductility |

| Mn | ≤ 0.05 | Adds strength & oxidation resistance |

| Mg | ≤ 0.03 | Improves hardness and structural integrity |

| Cr | trace | Prevents corrosion & increases hardness |

These compute as a harmonious alloy matrix well balanced between strength, toughness, and resistance necessary for high-fidelity plate usage.

Technical Parameters Table

| Specification | Description | Typical Values |

|---|---|---|

| Thickness Range (mm) | Plate Thickness | 0.20 - 0.60 mm (standard) |

| Width x Length Range | Customizable as per customer | Up to 1300 mm wide, 2500 mm long |

| Surface Finish | Anodized + Chemically Treated | Uniform, non-porous |

| Density (g/cm³) | Aluminum Alloy | Approx. 2.7 g/cm³ |

| Heat Conductivity | Thermal Conductivity (W/m-K) | 210 – 230 |

| Hardness (HV) | Vickers Hardness | 35 – 45 |

| Resistivity (Ohm∙m) | Electrical Resistivity | 2.65E-8 |

Typical Applications

Thermal Computer to Plate Systems for Print ShopsIdeal substrate for direct thermal CTP platemaking processes employed in newspapers, magazines, packaging labels, and commercial sheetfed printing. Ensures stable, precise reproduction of fine text, halftones, and photorealistic graphics.

Commercial and Flexographic Printing PlatesVery compatible with thermal flexographic plates requiring high mechanical resistance during repeated runs and compatible transfer sensitivity to thermal imagers.

Packaging IndustryUsed extensively to produce thermal plates capable of withstanding multiple imprinting cycles in packaging of foodstuffs, pharmaceuticals and consumable products.

Security and Specialty PrintingWithstands complex security printing requirements, integrates well with thermally based digital imager solutions requiring no post-processing such as solvent washes.

Newspaper & Magazine ProductionHigh tensile and dent-resilient properties make it suitable for both short and long jumbo roll runs typical in periodic publication presses.

Quality Assurance

All our printing plate aluminum materials undergo strict in-house and third party inspection to ensure dimensions, surface flatness, purity grade, and coating thickness are within/+ tight tolerance (typically < ±0.005 mm thickness variation and surface roughness below Ra < 0.20 µm). Continuous improvements are also handled through precise metallurgical process control.

Working with aluminum CTP plates daily, I've developed a deep appreciation for the intricate balance required in their manufacturing. It's not just about the aluminum itself; the alloy composition is crucial. Too much silicon, and you risk pitting and uneven imaging; too little, and the plate lacks the necessary strength and durability for high-volume printing. Furthermore, the anodization process is a fascinating blend of art and science. Getting the oxide layer just right—neither too thin to resist abrasion nor too thick to impede image development—is to producing a high-quality plate with consistent imaging results across a large batch. We constantly fine-tune parameters, from pre-treatment chemicals to anodizing voltage and time, to optimize plate performance and minimize waste.

Beyond the technical aspects, I've noticed a shift in customer expectations. The demand for longer plate life, sharper image resolution, and improved environmental friendliness is pushing innovation within our industry. This means we're constantly new alloy formulations, surface treatments, and even more sustainable methods of manufacturing and disposal. Seeing firsthand how improvements in our process directly translate to a better product for our clients, and potentially a smaller environmental footprint, is a very rewarding aspect of this job. The quest for that perfect balance between performance, cost, and sustainability is what keeps our work both challenging and exciting.

https://www.al-alloy.com/a/printing-plate-aluminum-plate-thermal-ctp-plate.html