Violet Photopolymer WEB CTP Plate

In the realm of modern printing technology, the evolution of Computer-to-Plate (CTP) systems has dramatically enhanced print quality, turnaround time, and production efficiency. Among these innovations, the Violet Photopolymer WEB CTP Plate stands out as a leading-edge product, offering unparalleled precision and durability for newspaper and web offset printing.

Violet Photopolymer WEB CTP Plate

Violet Photopolymer WEB CTP Plates are specialized photopolymer plates engineered specifically for violet laser based CTP systems, primarily used in continuous web offset presses. Constructed predominantly from an aluminum base coated with a precise photopolymer emulsion that is sensitive to violet laser wavelengths (approximately 405 nm), these plates combine mechanical strength with extremely fine image reproduction capability.

Working with violet photopolymer WEB CTP plates presents a unique set of challenges and advantages compared to other CTP plate technologies. Their flexibility, stemming from the web format, allows for high-speed, automated processing, crucial for maintaining our factory's high-volume production targets. However, this very flexibility demands precise control over tension and handling during the entire process, from unwinding to plate exposure and processing. A slight misalignment or inconsistent tension can lead to significant plate defects, manifesting as pinholes, scratches, or variations in image density, ultimately impacting print quality and necessitating costly re-runs. We've found meticulous maintenance of our processing equipment, particularly the rollers and vacuum systems, to be paramount in mitigating these issues.

Beyond the operational aspects, the inherent characteristics of violet photopolymer itself play a critical role. While offering excellent resolution and fine detail reproduction, the sensitivity to ambient light and processing chemicals requires strict adherence to established protocols. Contamination, even minor, can severely compromise the plate's sensitivity and image fidelity. We've learned that rigorous cleanliness in our darkroom and processing areas is non-negotiable. Moreover, optimizing the exposure parameters based on factors such as plate age, ambient temperature, and the specific violet laser used is crucial for achieving consistent results and maximizing plate lifespan. Regular quality control checks, including densitometry and visual inspection, are vital to fine-tune the process and minimize waste.

Unlike traditional thermal or UV-exposed photopolymer plates, violet-sensitive plates leverage the specific energy of violet laser devices, enabling faster imaging speeds and higher resolution outputs, eliminating post-exposure processing stages such as preheating or baking in many cases — thereby streamlining production.

Core Functions and Technological Advantages

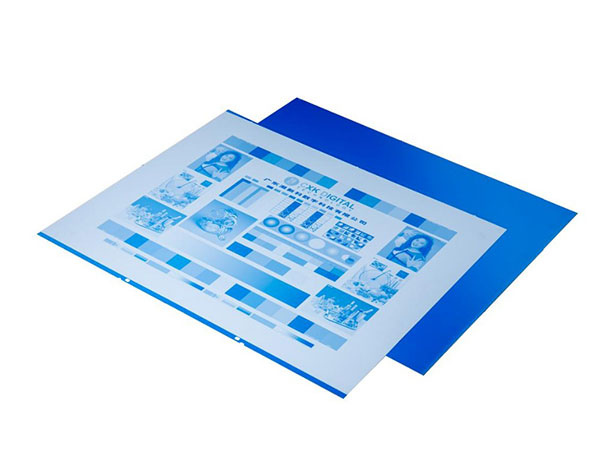

High Resolution and Tonal AccuracyThe violet photopolymer layer offers exceptional image sensitivity, delivering resolutions up to 2400 dpi with sharp tonal graduations. This capacity is vital for reproducing fine details, especially in high-speed rotary web presses used in newspaper printing.

Excellent Chemical ResistanceThese plates exhibit heightened resistance to processing chemicals, solvents, and pressroom environments, which reduces plate wear and subsequent print defects, extending plate lifespan during long print runs.

Fast Passes and Longer RunlengthsOptimized polymer cross-linking allows increased durability under heat, pressure, and ink exposure. Typical run lengths range from 100,000 to 200,000 impressions depending on press conditions, considerably improving productivity for large-volume web presses.

Environmental & Process BenefitsMany violet photopolymer plates are developed with non-phenol adhesives and require minimal or no chemical processing after imaging (processless or chemistry-lite options). This innovation significantly reduces water usage, chemical waste, and hazardous release, meeting strict environmental compliance such as ISO 14001 and RoHS standards.

Technical Parameters and Implementation Standards

| Parameter | Specification | Test Method / Standard |

|---|---|---|

| Plate Material | 1050 Pure Aluminum Alloy | JIS H4000 / ASTM B209 |

| Alloy Temper | O (annealed) | ASTM B209 Fully Annealed |

| Plate Thickness | 0.15-0.30 mm | Micrometer/ASTM E562 |

| Photosensitive Layer Thickness | 3-4 μm | Optical Microscopy |

| Wavelength Sensitivity | 405 nm (Violet Laser) | Spectral Response Analysis |

| Run Length | 100,000 − 150,000 impressions | Press Manufacturer’s Standards |

| Resolution Capability | Up to 2400 dpi | CTP Plate Manufacturer Data |

| Processing Type | Processless / Chemistry-light | Manufacturer's Process Guidelines |

| Imaging Output Speed | Up to 10 plates/hour | Controlled Test Environment |

| Minimum Dot | 3% or 8 μm dot diameter | Plate Supplier Norms |

Chemical Properties Table

| Component | Approximate Percentage | Role in Plate Development |

|---|---|---|

| Aluminum (Al) | 99.5% | Plate substrate, provides dimensional stability and heat conduction |

| Photopolymer Resin | ~3-5% | Photosensitivity and image formation through cross-linking |

| Sensitizers | Trace | Enhances violet wavelength sensitivity |

| Adhesives / Binders | ~2-3% | Electrical adhesion and mechanical robustness |

| Surface Treatments | Trace | Enhances ink and water affinity during printing |

Alloy Tempering and Plate Base Conditions

The plate base is manufactured using ASTM B209 Grade 1050 grade aluminum with O-temperfully annealed, ensuring the plate substratum exhibits:

- Minimal coefficient of expansion: Essential to control grid stability during rapid press cycling and multiple environmental exposures.

- High Surface Hardness (≈HV 110-130): To withstand repeated washing and shipping stresses.

- Exceptional Flatness and Smoothness: Essential for crater-free printing balance.

Furthermore, subtle anodizing pre-treatments may be employed to boost adhesion and print quality by creating a nano-porous oxide layer allowing uniform photopolymer coating bonding, thus ensuring maximal production durability.

Implementation in the Printing Industry

Primarily applied within newspaper printing corridors, the Violet Photopolymer WEB CTP Plates prove indispensable in high-speed, high-volume print environments. Their ideal functionality complements web press conditions where continuous roll printing requires plates that withstand mechanical stress and variable moisture conditions while preserving extreme imaging fidelity through extended runs.

Additionally, this technology bridges sustainability targets for print producers focusing on environmental impact reduction via minimal chemical processing and energy-efficient imaging systems.

End-User Benefits at a Glance:

- Exceptional clarity and durability adapted to high-speed web-fed impressions

- Reduced processing and environmentally-friendly operational dynamics

- Ease of integration with standard violet laser CTP systems and web press workflows

- Cost-effective long-run print stable plates

https://www.al-alloy.com/a/violet-photopolymer-web-ctp-plate.html