Ps printing ps material

PS printing PS material refers to polystyrene (PS) sheets, films, and formed parts engineered specifically for printing processes such as screen printing, UV offset, digital UV flatbed, pad printing, and label/graphic lamination. It is valued for its excellent surface uniformity, stable whiteness, high stiffness at low thickness, and cost-effective performance in indoor visual communication, packaging, and point-of-sale graphics.

For brands, converters, and display fabricators, PS printing material sits in a sweet spot: it delivers a clean printed look with predictable forming behavior while keeping production efficient and economical.

What makes PS a strong printing substrate

PS is an amorphous thermoplastic known for its clarity in natural form and high brightness when pigmented white. In printing grades, manufacturers typically optimize:

- Surface energy and smoothness for ink wetting and dot control

- Sheet flatness for consistent registration on press

- Opacity/whiteness for vivid color development

- Caliper stiffness so thin sheets remain rigid for signs and inserts

- Thermoformability for shaped packaging and display components

PS printing materials are usually supplied as solid PS sheets or co-extruded structures where the top layer is tuned for print adhesion and scuff resistance.

Common product forms and finishes

| Product Form | Typical Thickness Range | Common Finish Options | Typical Use |

|---|---|---|---|

| Solid PS sheet (white) | 0.2–2.0 mm | Gloss / Matte / Velvet | Posters, inserts, indoor signs |

| High-impact PS (HIPS) printing sheet | 0.3–3.0 mm | Matte / Haircell / Textured | POS displays, durable signage, trays |

| PS film/roll stock | 100–500 μm | Gloss / Matte | Labels, sleeves, laminated graphics |

| Co-extruded print-face PS | 0.4–2.0 mm | Controlled topcoat-like layer | High-quality graphics, better rub resistance |

features customers notice immediately

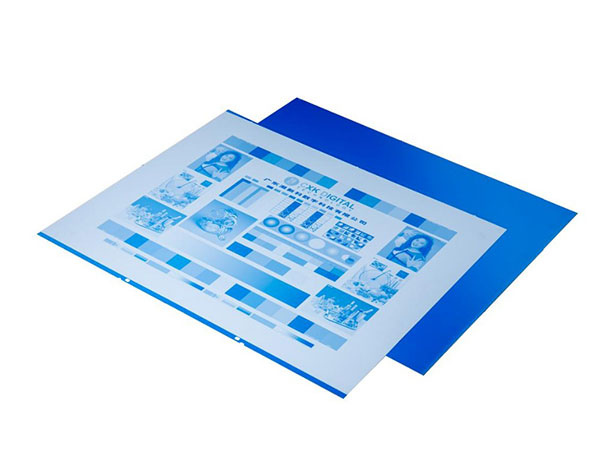

Crisp image quality

PS printing sheets can be produced with a very uniform surface, enabling sharp text, smooth gradients, and clean solids. Matte versions reduce glare in retail lighting, while gloss versions maximize saturation and perceived contrast.

Fast production flow

PS cuts cleanly with die cutting and CNC routing, and many grades accept UV-curable inks with short turnaround. For converters, this means less waiting, faster stacking, and efficient finishing.

Strong stiffness-to-cost ratio

Compared with some higher-end sign plastics, PS offers rigidity at low thickness without a premium price point-ideal for short-cycle promotions and high-volume inserts.

Thermoforming-friendly behavior

HIPS and forming grades can be heated and shaped into trays, blisters, and display contours. Printed sheets are often formed after printing when inks and process are selected correctly.

Typical chemical composition (base polymer and additives)

PS is primarily a polymer of styrene. Printing-grade PS usually includes pigments and stabilizers chosen for visual appearance and processing stability.

| Component | Typical Presence | Function in Printing PS Material |

|---|---|---|

| Polystyrene (PS) matrix | Primary | Base resin providing stiffness and surface quality |

| Rubber modifier (for HIPS) | Optional | Impact improvement; better toughness for handling |

| Titanium dioxide (TiO₂) | Common in white sheets | Opacity, whiteness, color pop |

| Processing aids / lubricants | Small amounts | Improved extrusion, sheet release, cutting behavior |

| Antioxidants / thermal stabilizers | Small amounts | Helps maintain color and melt stability |

| Antistatic additive | Optional | Reduces dust attraction; improves print cleanliness |

Note: exact formulation varies by supplier and target printing method.

Technical specifications (typical ranges)

Values depend on grade (GPPS vs HIPS), thickness, and surface finish. The table below reflects common industry ranges for printing-focused PS sheets.

| Property | Typical Range | Notes for Customers |

|---|---|---|

| Density | 1.04–1.07 g/cm³ | Affects sheet weight and shipping cost |

| Tensile strength | 20–45 MPa | HIPS typically lower than GPPS but tougher |

| Flexural modulus | 1.7–3.2 GPa | Higher modulus supports flat signage |

| Izod impact (notched) | 2–12 kJ/m² | HIPS at the higher end |

| Vicat softening temperature | 85–105 °C | Guides forming and service temperature |

| Gloss (60°) | 10–95 GU | Matte to high-gloss options |

| Haze (clear PS) | <2–10% | Clear grades for packaging windows |

| Surface tension (dyne level) | 36–42 dyn/cm | Higher helps ink wetting and adhesion |

Printing compatibility and process notes

| Printing Method | Suitability on PS | Best Practices |

|---|---|---|

| UV flatbed digital | Excellent | Use UV inks tuned for styrenics; confirm curing to avoid odor/soft surface |

| Screen printing | Excellent | Choose solvent/UV systems compatible with PS; manage squeegee pressure to avoid distortion |

| UV offset | Good to excellent | Control sheet flatness, static, and pile temperature |

| Pad printing | Good | Useful for formed PS parts and small graphics |

| Hot foil stamping | Good | Works well on smooth gloss; check heat limits |

| Lamination | Good | Use PS-safe adhesives; test for silvering on matte surfaces |

PS can be sensitive to aggressive solvents. Ink selection matters: a formulation that is perfect on PVC may craze PS. For reliable production, pre-test with your exact ink, cure settings, and post-finishing steps.

Where PS printing PS material shines: applications

Retail and point-of-sale graphics

PS is widely used for shelf talkers, wobblers, price rails, aisle blades, hanging signs, and promotional panels. The material stays stiff enough to look premium, yet it remains economical for frequent campaign changes. Matte PS is popular for anti-glare displays under strong LEDs.

Packaging and formed display components

HIPS printing sheets are chosen for thermoformed trays, product cradles, cosmetic inserts, and shaped display fronts. The ability to print high-quality branding and then form it into a 3D part makes PS a practical option for semi-rigid packaging and merchandising.

Indoor signage and back panels

For indoor environments, PS offers stable appearance and clean edges after cutting. It is often used as mounting panels, menu boards, branded separators, and decorative inserts where weather resistance is not the primary requirement.

Educational, seasonal, and event graphics

Short-life events benefit from PS's speed and affordability. PS works well for temporary direction signs, photo props, exhibit messaging, and seasonal décor panels.

Selection guide: choosing the right PS grade

| Customer Need | Recommended PS Type | Why it Fits |

|---|---|---|

| Maximum image sharpness, smooth gloss | GPPS print-grade sheet | High surface clarity and stiffness |

| Better toughness for handling and shipping | HIPS printing sheet | Improved impact resistance, less cracking |

| Low glare under store lighting | Matte PS / velvet finish | Better readability and premium feel |

| Forming after printing | Thermoformable HIPS/PS | Controlled shrink and better forming window |

| High opacity for bold colors | TiO₂-loaded white PS | Strong background whiteness and hiding power |

Limitations and how customers can avoid issues

| Potential Challenge | What It Looks Like | Practical Mitigation |

|---|---|---|

| Solvent stress cracking | Fine crazing near ink areas | Use PS-compatible inks; reduce aggressive cleaners |

| Heat distortion | Warping during curing/stacking | Control UV dose and pile temperature; allow cooling |

| Static and dust | Specks in solid colors | Antistatic grades, ionizing air, clean packing |

| Outdoor UV aging | Yellowing or brittleness | Prefer PETG/PC/PMMA outdoors; use UV-stabilized alternatives if required |

PS printing material is primarily an indoor and controlled-environment solution. For long-term outdoor signage, other polymers typically outperform PS.

PS printing PS material is a versatile, print-friendly polystyrene substrate designed for fast, clean, high-impact graphics and efficient converting. With options from high-gloss GPPS to tougher HIPS, it supports a wide range of commercial applications-from POS signage and promotional panels to thermoformed packaging inserts. When paired with compatible inks and appropriate process settings, PS delivers an excellent balance of appearance, stiffness, and cost, making it a dependable choice for high-volume visual communication and packaging workflows.