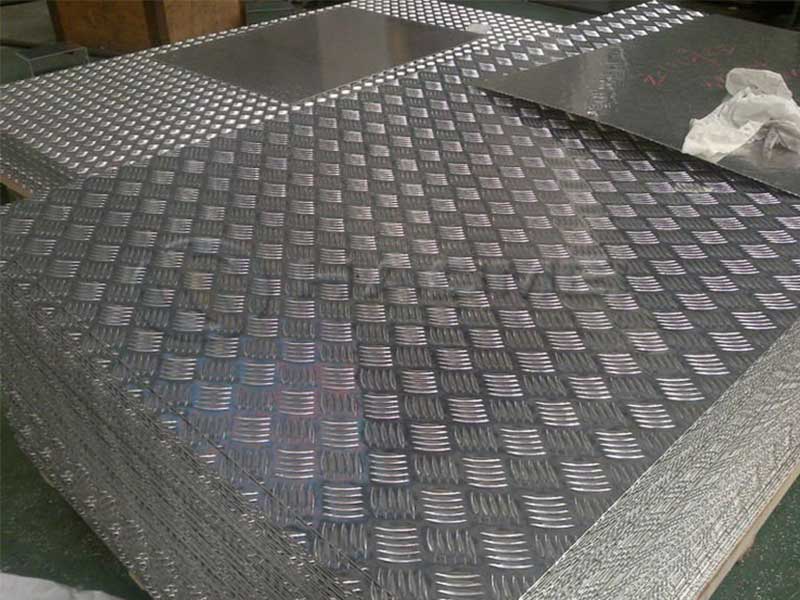

Tread aluminum sheet plate

Tread aluminum sheet plate, also known as aluminum diamond plate or checker plate, is a uniquely patterned aluminum sheet designed with repetitive raised surface patterns or rub points, aimed at enhancing slip resistance, durability, and aesthetics. Commonly used in industrial flooring, transportation vehicles, stairways, ramps, and architectural applications, the tread plate serves both functional and decorative purposes.

These sheets offer the lightweight benefits and corrosion resistance of aluminum combined with a textured surface for safer walking and handling conditions.

Composition and Alloy Specification

The most popular alloy series used for tread aluminum sheet plates are the 1000, 3000, and 5000 series. Each offers a different combination of strength, corrosion resistance, formability, and cost-effectiveness.

| Alloy Series | Common Grades | Typical Applications | Characteristics |

|---|---|---|---|

| 1000 Series | 1050, 1100 | Lightweight, decorative canvases | Excellent corrosion resistance, excellent formability, lower strength |

| 3000 Series | 3003 | Decorative and roofing applications | Good corrosion resistance, higher strength than 1000 series |

| 5000 Series | 5052, 5083 | Marine, transportation, industrial floorings | Excellent corrosion resistance, high strength, good weldability |

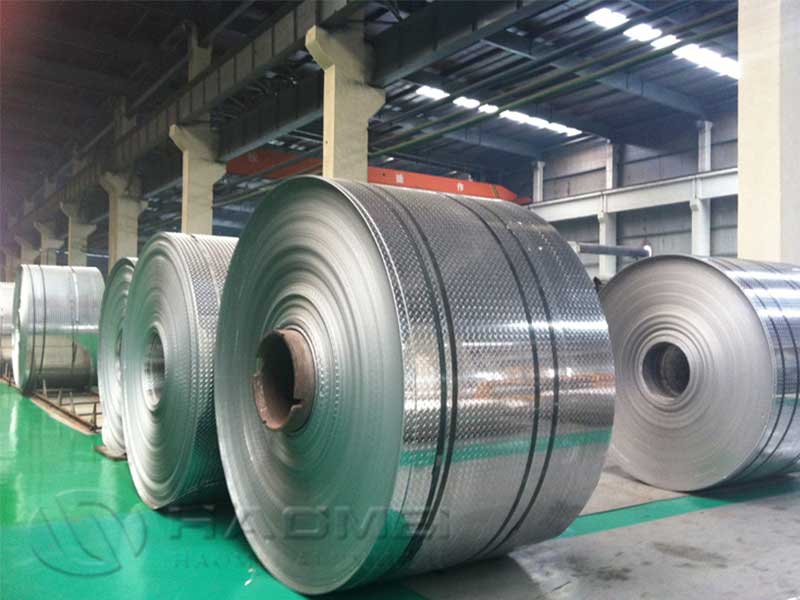

Product Parameters and Dimensions

Tread aluminum sheet plates come in various thicknesses, standard widths, and lengths depending on customer requirements, destination markets, and industrial standards.

| Parameter | Typical Values |

|---|---|

| Thickness | 1.0 mm to 6.0 mm |

| Width | 1000 mm to 2000 mm |

| Length | 2000 mm to 6000 mm |

| Pattern Height | Approximately 0.3 mm to 1.5 mm |

| Weight | Dependent on gauge and aluminum alloy |

Temper and Mechanical Properties

The temper of the aluminum affects the hardness, tensile strength, and ductility of tread plates, heavily influencing their suitability for bending, welding, and pressure resistance.

| Alloy & Temper | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| 5052-H32 | 215 | 275 | 10-15 | 85-95 |

| 3003-H14 | 110 | 140 | 10-16 | 35-55 |

| 1100-H24 | 55 | 80 | 8-12 | 23-28 |

Implementation Standards and Quality

Manufacturing and testing of tread aluminum sheet plates conform to international standards to ensure consistency and performance:

- ASTM B632: Standard Specification for Aluminum Checkered or Tread Plate

- MIL-DTL-23053: Military standard for aluminum sheet and plate

- EN 485-2: Aluminum and aluminum alloys - Sheet, strip and plate - Mechanical properties

- JIS H 4100: Japanese industrial standards for aluminum milled products

Quality checks include surface pattern verification, thickness tolerance, mechanical properties testing, corrosion resistance (salt spray tests), and dimensional accuracy.

Chemical Composition Table (Example: Alloy 5052)

| Element | Min (%) | Max (%) |

|---|---|---|

| Aluminum (Al) | Balance | |

| Magnesium (Mg) | 2.2 | 2.8 |

| Chromium (Cr) | 0.15 | 0.35 |

| Iron (Fe) | - | 0.4 |

| Copper (Cu) | - | 0.1 |

| Manganese (Mn) | - | 0.1 |

| Silicon (Si) | - | 0.25 |

| Zinc (Zn) | - | 0.1 |

Surface Finish and Pattern Designs

Tread plates are typically supplied with highly defined, embossed patterns, which enhance friction and improve drainage and traction surfaces.

Common patterns include:

- Diamond Tread/Checker Plate: Raised diamond shapes repeating on the surface.

- Flat Rolled with Rub Pattern: Slightly elevated bump patterns spaced horizontally.

- Large Scale Tread: Wider surfaces for heavy machinery and vehicle usage.

Finishes may be left mill-finished, anodized for enhanced wear and corrosion resistance, or painted/coated depending on the application.

Applications

- Industrial Flooring & Platforms: Prevents slipping in factories and processing plants.

- Transportation: Used on truck beds, trailers, walkways, ramps and public transport stairs.

- Marine Industry: Deck plating and bulkhead protections due to corrosion resistance.

- Architectural Uses: Wall cladding, decorative facades, elevator trimming.

- Food Processing and Chemical Plants: Where hygiene and corrosion resistance are crucial alongside slip resistance.