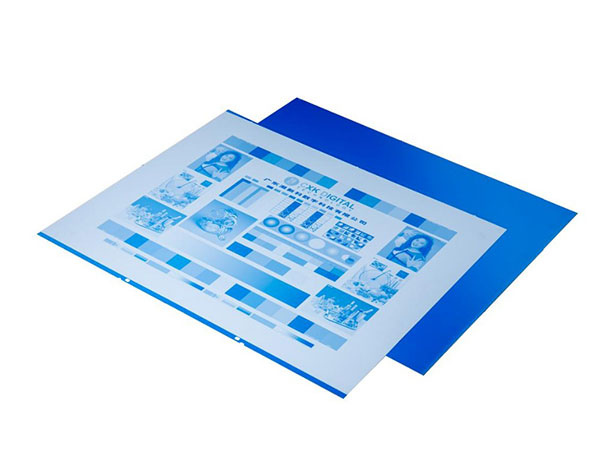

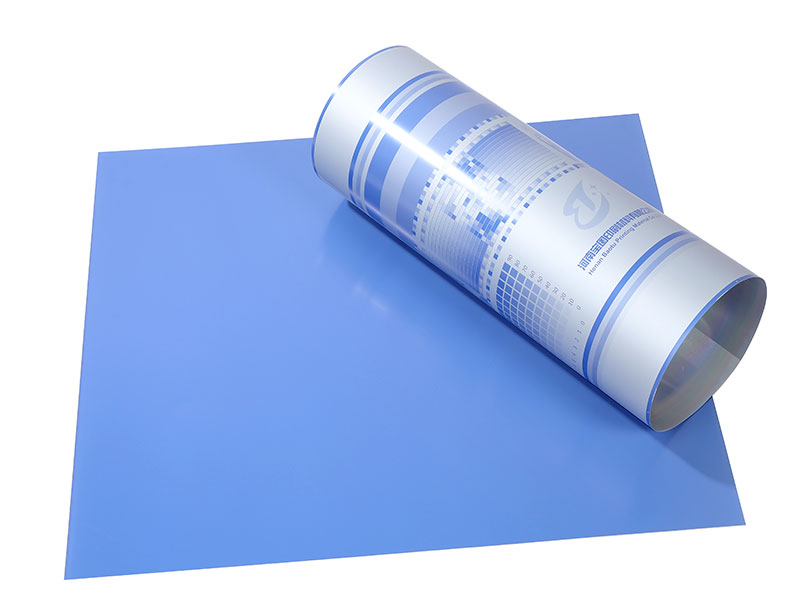

Pure Aluminum Lithographic PS Plate Thin Aluminum Plate

Pure Aluminum Lithographic PS Plate Thin Aluminum Plate is a highly specialized product designed primarily for use in the printing industry. Renowned for its superior surface quality, excellent mechanical properties, and optimal chemical composition, this aluminum plate is tailored to meet the rigorous demands of lithographic photopolymer plates (PS plates).

Features

- High Purity Aluminum: Exceptional purity guarantees uniform surface texture and high corrosion resistance.

- Superior Surface Finish: Extremely smooth and consistent finish suitable for lithographic plate coating.

- Optimal Thickness: Thin gauge aluminum that supports high-resolution plate making with flexibility.

- Excellent Mechanical Strength: A balance between strength and ductility aids in easy processing and long-lasting performance.

- Oxidation Resistance: Enhanced oxide film ensures durability during printing processes and reduces surface defects.

- Good Thermal and Electrical Conductivity: Supports heat dissipation during plate processing to improve efficiency.

Applications

| Industry | Typical Use Cases |

|---|---|

| Printing Industry | Lithographic PS Plates (Processing plates for offset printing) |

| Packaging | Production of printing plates for packaging materials |

| Advertising | High definition, multi-color printing plates |

| Fine Art Prints | Plates requiring exquisite photo sensitivity and print detail |

The product is primarily applied where ultra-fine surface and precise dimensions are critical to achieving sharp transferable images on printing plates.

Benefits

- Improved Plate Quality: Outperforms general aluminum plate offerings with smoother surface preventing pinholes and defects.

- Consistent Size & Shape: Ensures accuracy in dimensions and flatness suitable for automated lithographic plate mounting.

- Cost Efficiency: Enhanced processing rate reduces waste and increases throughput during plate making.

- Offers Stability Over Time: Minimizes chemical degradation and mechanical warping during the printing lifecycle.

Technical Specifications and Properties

Chemical Composition

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Aluminum (Al) | 99.5 | - |

| Silicon (Si) | - | 0.20 |

| Iron (Fe) | - | 0.15 |

| Copper (Cu) | - | 0.05 |

| Manganese (Mn) | - | 0.03 |

| Magnesium (Mg) | - | 0.02 |

| Zinc (Zn) | - | 0.05 |

| Titanium (Ti) | - | 0.03 |

| Others (Individual) | - | 0.03 |

| Others (Total) | - | 0.10 |

Note: High purity aluminum ensures minimal impurities, optimizing surface quality suitable for lithographic printing.

Mechanical Properties

| Property | Value | Test Method |

|---|---|---|

| Tensile Strength | 50 - 90 MPa | ASTM B557 |

| Yield Strength | 30 - 50 MPa | ASTM B557 |

| Elongation at break | ≥ 20 % | ASTM B557 |

| Hardness (Brinell) | 25 - 40 HB | ASTM E10 |

| Density | 2.70 g/cm³ | ASTM B271 |

Physical and Dimensional Specifications

| Parameter | Typical Value | Remarks |

|---|---|---|

| Thickness | 0.1 mm - 0.3 mm | Custom order possible |

| Width Range | 500 mm - 1000 mm | Based on customer need |

| Length Range | 1000 mm - 2000 mm | Standard coil length |

| Surface Finish | Matt/Smooth | Suitable for coating |

| Flatness Tolerance | ≤ 0.1 mm per meter | Critical for litho plates |

Performance Analysis

Surface Quality: The refined aluminum polishing process creates a surface with low roughness (~0.1 µm Ra), which contributes to uniform emulsion coating and optimal adherence in plate making.

Oxidation Behavior: Controlled oxide film formation simplifies chemical treatments during plate preparation, promoting consistent imaging quality and durability.

Processing Advantages: Its mechanical flexibility lowers risks of damage during cutting, bending, or plate mounting, contributing to production efficiency.

https://www.al-alloy.com/a/pure-aluminum-lithographic-ps-plate-thin-aluminum-plate.html