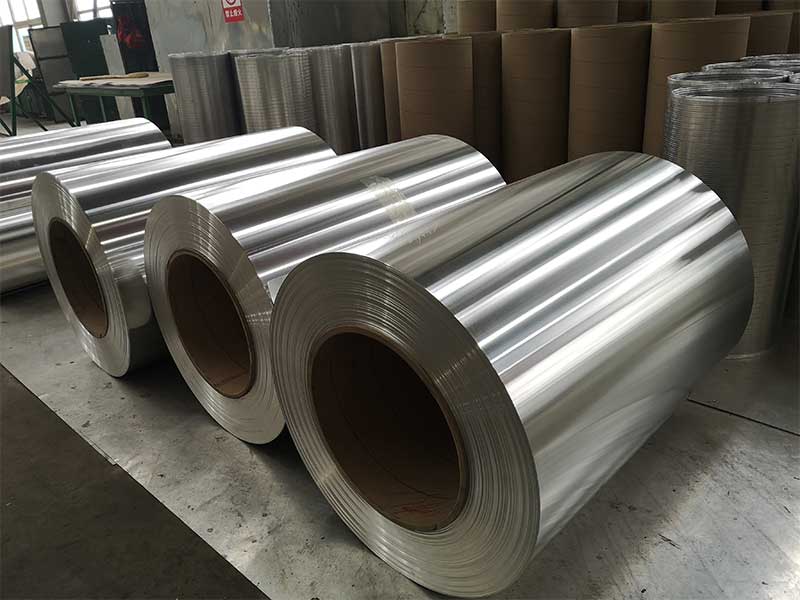

1050 1060 1100 3003 5052 aluminum coil

Aluminum coils form the bedrock of numerous industrial applications, featuring varied alloy grades each tailored to meet specific performance criteria. Among the most prominent and versatile alloys used in coil form are 1050, 1060, 1100, 3003, and 5052.

An aluminum coil is essentially a flat, rolled sheet of aluminum that can range widely in thickness and width. Coils undergo various surface finishes and mechanical treatments, enhancing attributes such as strength, corrosion resistance, weldability, and formability. Distinctively, each aluminum alloy marked by its numerical code signifies a precise metallurgical makeup that dictates its eventual properties.

Chemical Composition and Material Parameters

| Alloy | Main Alloying Elements (% max) | Typical Thickness (mm) | Temper Ranges | Density (g/cm³) | Melting Point (°C) |

|---|---|---|---|---|---|

| 1050 | Al ≥ 99.5, Si ≤ 0.25, Fe ≤ 0.4 | 0.2 - 3.0 | O (annealed), H14 (half hard) | 2.71 | 660–675 |

| 1060 | Al ≥ 99.6, Si ≤ 0.25, Fe ≤ 0.35 | 0.2 - 3.0 | O, H12, H14 | 2.71 | 660–675 |

| 1100 | Al ≥ 99, Cu 0.05–0.20, Fe ≤ 0.95 | 0.3 - 4.5 | O (annealed), H14 | 2.71 | 660–675 |

| 3003 | Al ~ 96.8, Mn 1.0–1.5, Cu ≤ 0.1 | 0.3 - 4.0 | O, H14, H24 | 2.73 | 640–655 |

| 5052 | Al ~ 97.25, Mg 2.2–2.8, Cr ≤ 0.25 | 0.3 - 3.5 | O, H32 (strain hardened), H34 | 2.68 | 590–650 |

Note: Temper codes - O for annealed (soft), H followed by a number indicating strain hardening degree.

Unique Features and Their Metallurgical Underpinnings

1050 Aluminum CoilKnown for its purity (99.5%+ aluminum content), 1050 excel appreciably in electrical and thermal conductivity — up to 61% IACS (International Annealed Copper Standard). Its outstanding corrosion resistance stems from lack of alloying elements, although its tensile strength remains limited (~40–60 MPa in fully annealed).

1060 Aluminum CoilNear identical to 1050 in purity but often regarded as a higher-grade compliant alloy due to stricter impurity controls. 1060 offers improved ductility at the cost of marginally lower strength. Optimal for fencing, flashing, or various architectural usage emphasizing malleability.

1100 Aluminum CoilIncorporating a small addition of copper (up to 0.2%), 1100 distinguishes itself by providing slightly higher tensile strength without significant compromise in corrosion resistance. Cu addition also aids in work-hardening response, facilitating medium-strength components or packaging usage.

3003 Aluminum CoilAlloyed primarily with manganese, 3003 crosses a critical threshold by striking excellent corrosion resistance and moderate strength (~130 MPa stress), with sufficient ductility. This 1xxx heirloom reflects random impurity aluminums’ evolution; for instance, it withstands marine atmosphere exposures exceptionally. It typically garners H14 temper for commercial rigid sheets.

5052 Aluminum CoilMagnesium strengthens 5052 alloy by precipitation hardening phenomena, typically fitness-packed in capacious marine and chemical service points for its top-tier corrosion resistance—outweighing 3003 in extreme environments. Temper marks like H32 impart higher yield (minimum 228 MPa) translating to robust aerospace or automotive cladding domains.

Application Insights Based on Alloy Characteristics

Electrical and Thermal Industrial Use1050 and 1060 aluminum coils, with their supersaturated aluminum content, are rigorously used in conductive applications such as transformer windings, rooftops reflecting solar gradients, capacitor plates due to electrical purity, and heat exchangers.

Packaging and Kitchenware1100 aluminum coil — resistant to corrosion, forming and small strengthening attributes make it ideal for household products — from cooking utensils, impervious packaging foils or cans where ductility and non-toxicity matter.

Decorative and Structural Panels3003 works wonders as siding, roofing, wall panels; anchored by better formability than 1xxx-series alloys and moderate strength-ready after treatment. Its aesthetic surfaces are often painted due to anodizing efficiencies.

Marine Level and Corrosive ServiceEnvironments laden with salts and aggressive elements beckon 5052 coils whose Mg-Cr Keystoneائها coupling bring abrasion and chemical-resistive top layers, sidestepping salts’ debilitating actions widely used in boat hulls, shipbuilding flotation systems, and chemical tanks.

Implementation Standards & Temper Treatments

- ASTM B209: Highest standard governing aluminum sheet and coil production conformance.

- Temper Selection: Source condition strictly depends upon demand for ductility or strength — O temper for bending-shaped jobs; H14/H32 for corrugated panels or structural sheathings.

- Finish Varieties: Mill Finish (critical for post-process manufacture), Anodized — for protective, decorative coating application aligning especially on 3003 and 5052.

Distinctive Metallurgical Viewpoint

Viewing these aluminum coils through their elemental parade and anisotropy behaviors reveals how chemically minor doping (Mn in 3003, Mg in 5052, and Cu in 1100) induces transformational shifts in mechanical patterns and corrosion profiles. Purity prioritizes ductility and electrical traits at one echelon, while controlled enhancements! accomplish resilience balanced with workability constraints decisively at another — embedding each grade into industrial armor furnaces and room temperature forge militias ly.

https://www.al-alloy.com/a/1050-1060-1100-3003-5052-aluminum-coil.html