1070 1100 5052 anodized aluminum mirror sheet coil

Anodized aluminum mirror sheet coils are premium materials widely used across industries for their aesthetic appeal and excellent functional properties. Specifically, 1070, 1100, and 5052 anodized aluminum mirror sheets is know for their enhanced corrosion resistance, high reflectivity, and versatile applications.

What is Anodized Aluminum Mirror Sheet Coil?

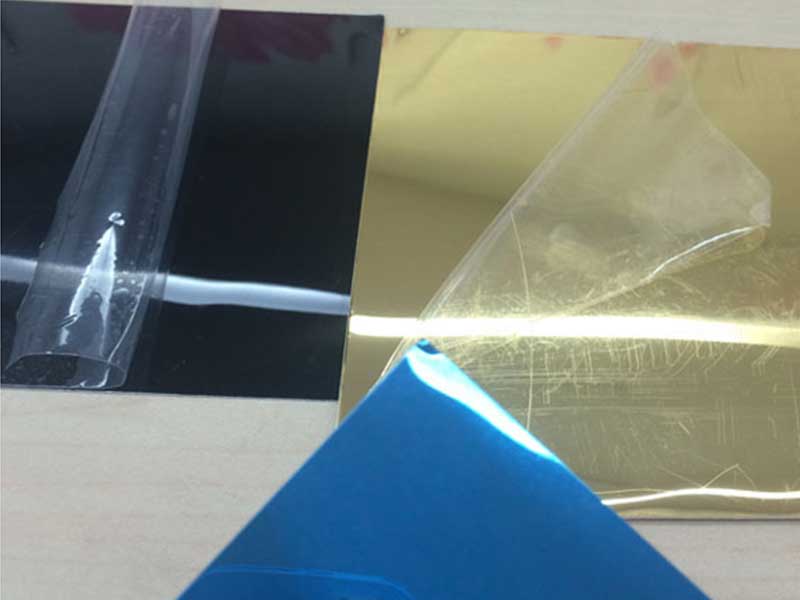

Anodizing is an electrochemical process that transforms the aluminum surface into a durable oxide layer, significantly improving abrasion resistance, corrosion resistance, and increasing surface hardness. When combined with the mirror finishing process, anodized aluminum sheets acquire a brilliant reflective finish with enhanced durability. The coil form provides ease in manufacturing and installation across various applications.

Alloy Types: 1070, 1100, and 5052

Different aluminum alloys yield distinct properties suited for various purposes. Below is a snapshot of each alloy:

| Alloy | Description | Primary Use | Strengths |

|---|---|---|---|

| 1070 | Commercially pure aluminum (>99.7%) | Decorative, chemical equipment | Exceptional corrosion resistance, excellent reflectivity |

| 1100 | Commercially pure aluminum (>99.0%) | Architectural, electrical | Superior formability, good corrosion resistance |

| 5052 | Aluminum-magnesium alloy | Marine, automotive, industry | High strength, excellent corrosion resistance especially in chloride environments |

Functions and Advantages

The anodized aluminum mirror sheet coils made from these alloys showcase several beneficial attributes:

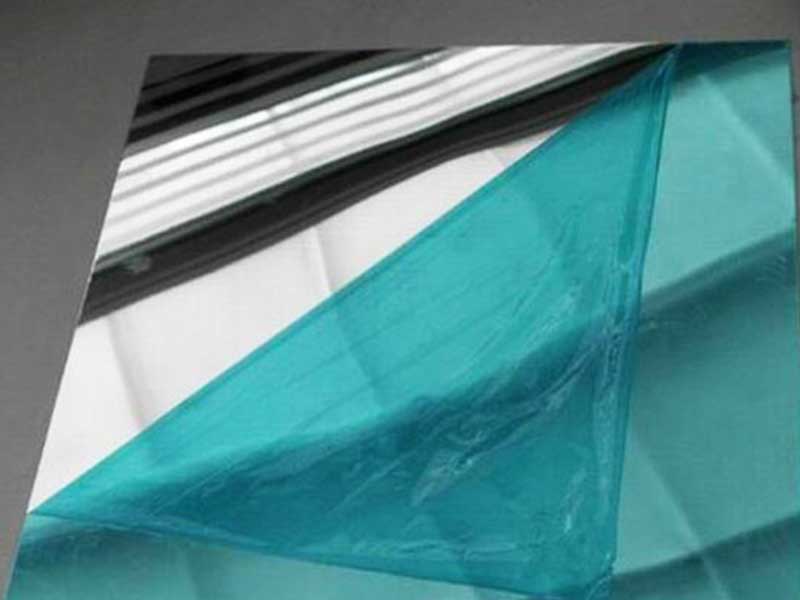

- Excellent Reflectivity: Mirror finish enhances aesthetics and lighting efficiency in reflective surfaces.

- Enhanced Durability: Anodizing makes the surface scratch-resistant and weatherproof.

- Corrosion Resistance: Protection from oxidation and extended longevity—crucial for outdoor or marine environments.

- Lightweight and Strong: Aluminum alloys balance weight and tensile strength perfectly for structural and decorative use.

- Ease of Fabrication: Superior formability to bend, cut, or weld into complex shapes.

- Low Maintenance: Smooth anodized surface prevents grime buildup and simplifies cleaning.

Technical Specifications and Physical Properties

Mechanical Properties

| Alloy | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|---|

| 1070 | H14 | 85-105 | 50-75 | 5-8 | 35-45 |

| 1100 | H14 | 95-110 | 40-67 | 10-18 | 35-50 |

| 5052 | H32 | 215-235 | 140-160 | 10-12 | 75-85 |

Physical Properties

| Property | 1070/1100 | 5052 |

|---|---|---|

| Density (g/cm³) | 2.70 | 2.68 |

| Melting Point (°C) | 660 | 607 |

| Thermal Conductivity (W/m·K) | 237 | 138 |

| Electrical Conductivity (% IACS) | 60-61 | 30-35 |

Chemical Composition (%)

| Element | 1070 | 1100 | 5052 |

|---|---|---|---|

| Aluminum | ≥ 99.7 | ≥ 99.0 | Balance |

| Magnesium | — | — | 2.2 - 2.8 |

| Silicon | ≤ 0.25 | ≤ 0.95 | ≤ 0.25 |

| Iron | ≤ 0.15 | ≤ 0.95 | ≤ 0.40 |

| Copper | ≤ 0.05 | ≤ 0.05 | ≤ 0.10 |

| Manganese | — | ≤ 0.05 | 0.10 - 0.40 |

| Zinc | ≤ 0.03 | ≤ 0.10 | ≤ 0.10 |

| Others | ≤ 0.03 | ≤ 0.05 | — |

Implementation Standards

These aluminum mirror sheets typically conform to recognized international and industrial standards, ensuring quality and performance:

- ASTM B491 – Specification for Aluminum and Aluminum Alloy Horizontal Continuous Castings

- ASTM B209 – Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- AA (Aluminum Association) Designations – Alloy and Temper identification

- GB/T 3880 – Aluminum alloy flat products (China Standard for flat aluminum products)

- JIS H4000 – Aluminum and aluminum alloy sheets specification (Japanese Industrial Standard)

- RoHS Compliant – Environmentally safe and free from hazardous substances

Alloy Tempering Conditions

The temper (or hardness treatment) impacts surface finish,the mechanical properties, and suitability for anodizing.

| Alloy | Common Tempers | Description |

|---|---|---|

| 1070 | H14 | Quarter hard; some strengthening from cold working |

| 1100 | H14 | Known for soft temper with good forming abilities |

| 5052 | H32 | Strain hardened and stabilized; medium strength with good workability |

Typical Applications

1070 Anodized Aluminum Mirror Sheets are widely employed in decorative architectural wall paneling, commercial signage, and gently corrosive environments such as laboratories and food-grade environments—thanks to its high purity and corrosion resistance.

1100 Anodized Aluminum Mirror Sheets shine in applications demanding superior formability and smooth surface finishing including lightweight decorative elements, ducting, lighting panels, and electronic components.

5052 Anodized Aluminum Mirror Sheets are favored for harsher applications like marine elements, automobile trims, exterior building cladding, and machinery parts due to the aluminum-magnesium alloy pedigree contributing extra strength and excellent resistance to saltwater corrosion.

1070, 1100, and 5052 anodized aluminum mirror sheet coils merge alluring aesthetics with robust physical performance. Their high purity and alloy composition coupled with anodized oxide protection yield materials with exceptional reflectivity, durability, and corrosion immunity. Standardized manufacturing, tempered enhancing mechanical strength, and friendly formability amplify their usability spanning architectural, marine, automotive, and decorative fields.

When selecting an anodized aluminum mirror sheet coil, choosing the right alloy and tempering based on durability and environment generates not only a gorgeous finish but a long-lasting solution that adds value cost-effectively.

For industries seeking visually appealing yet technically superior surface materials, anodized aluminum mirror sheets—particularly the 1070, 1100, and 5052 alloys—is know as an optimal choice balancing function and finesse effortlessly.

https://www.al-alloy.com/a/1070-1100-5052-anodized-aluminum-mirror-sheet-coil.html