8011 1235 3003 8021 O Blister Color Aluminum Foil

Aluminum foil, especially blister color aluminum foil, plays a pivotal role across various industries — from pharmaceutical packaging to food wrapping and industrial applications. Among the numerous aluminum foil grades available on the market, the standout performers based on functionality and technical advantages include alloys 8011, 1235, 3003, 8021, and various O temper options. these varieties not only reveals their unique characteristics but also suggests the best use-cases for blister color aluminum foil — a niche segment designed to combine durability with aesthetics.

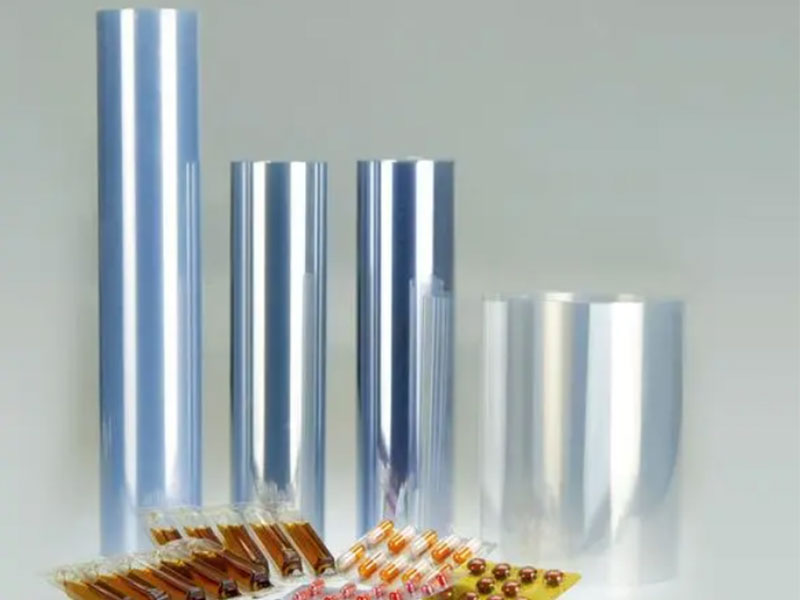

What is Blister Color Aluminum Foil?

Blister color aluminum foil refers to aluminum foil sheets enhanced with color printing or coating, primarily used for blister packaging applications. This kind of foil features excellent barrier properties combined with colored aesthetics, protecting products (like pharmaceuticals, cigarettes, or confectionaries) while providing brand-centric visuals and tamper evidence.

Decoding the Alloy Grades: 8011, 1235, 3003, 8021, and O Temper

The total performance of aluminum foil, particularly in blister color applications, hinges on specific grades or alloys. Here’s a deeper dive.

Aluminum Foil 8011: The Workhorse of Blister Foils

- Composition & Properties: The 8011 alloy is made primarily from aluminum with small percentages of iron and silicon, making it especially resistant to corrosion and current-carrying capacity (often used in electrical conductor applications as well).

- Functions: Its superb mechanical robustness makes it ideal for foldable blister packs that need extra strength without compromising thinness.

- Applications: Common in blister packaging for tablets and capsules in pharmaceutical boards; stores protective colors brilliantly due to superior coating adhesion.

Aluminum Foil 1235: High Purity and Superior Formability

- Composition & Properties: The 1235 grade contains typically 99.35% minimum purity aluminum with exceptional ductility and toughness.

- Functions: Offering excellent thermal conductivity and flexibility, 1235 alloy is outstanding for conductive blister foils needing tight seals and form-fit designs.

- Applications: Used widely in food-grade cups, lids, and blister packs.–ensures practical foil barrier with enhanced flowability under printing colors.

Aluminum Foil 3003 – Alloy of Strength with Malleability

- Composition & Properties: 3003 aluminums contain manganese as a alloying element that imparts medium strength along with corrosion resistance.

- Functions: This grade improves tensile properties, allowing higher mechanical protection for complex blister shapes, all while maintaining excellent color printing compatibility.

- Applications: Common in cosmetics blister packaging or specialized food wraps where both rigidity and aesthetics are important.

Aluminum Foil 8021 – Innovative Food & Pharma Premium Grade

- Composition & Properties: The 8021 alloy is designed explicitly for superior heat sealing and thin gauges without branching tears.

- Functions: It combines corrosion resistance like 8011 with enhanced sealing hermeticity crucial for blister foil usage.

- Applications: Predominantly employed in pharmaceutical blister packs, vitamin tubes, and other light-industrial sealing requirements — perfectly supporting coated color bonding and blister uplift structures.

O Temper Aluminum Foil: Maximum Flexibility & Softness

- Technical Detail: The “O temper” (soft or annealed stage) foil is mechanically softened through annealing after cold rolling. This process increases flexibility and elongation percentage but reduces some mechanical strength.

- Functions: These traits mean O temper foils adapt perfectly where folding, ironing, or blistering need seamless pliability. Thanks to its smooth foundation, color printing/decorative foil finishes cure elegantly.

- Application: Often combined with thin-print color techniques for blister packaging designs demanding bending and shaping without cracking or blueshift in color optics.

Why Blister Color Aluminum Foil is Essential Across Industries

- Protects Pharmaceutical Products: Aluminum is impermeable to moisture, gases, and contaminants.

- Supports Consumer Branding: Colored aluminum foils offer vibrant, customizable appearance decorating pharmacy and alimentary baskets — prompting brand recognition.

- Provides Mechanical Integrity: Effortlessly withstands mechanical stresses from transportation and shelf storage, thanks to unique alloy combinations.

- Grants Food Safety: Used in balloons, capsule overlays, or chocolate covers to maintain freshness without leaching aluminium ions.

Final Thoughts

Blister color aluminum foil in alloy grades 8011, 1235, 3003, 8021, and O temper emerge as specialized solutions each tailored to balance aesthetic appeal, barrier protection, mechanical protection, and seal integrity. Knowledge of these subtleties can redefine your foil choice strategy by assuring product shelf life, brand visibility, and flexibility needs are comprehensively met set against economic considerations.

Selecting the optimal blister color aluminum foil should revolve around detailed scrutiny of alloy type, temper flexibility, and function-driven coatings — ultimately helping manufacturers attain packaging innovation par excellence.

If you are interested in procuring high-quality, color printed aluminium foil suitable for various blister applications leveraging the best blends of technology and craftmanship, contact us for customized solutions tailored to your needs.

https://www.al-alloy.com/a/8011-1235-3003-8021-o-blister-color-aluminum-foil.html