Prepainted aluminum sheet with 0.02- 3mm thickness

Prepainted aluminum sheet (also called color-coated aluminum sheet or coil-coated aluminum) combines the light weight and formability of aluminum with a durable factory-applied coating system. In the 0.02–3.0 mm thickness range, it covers applications from ultra-thin decorative foils to robust architectural panels and industrial housings.

- features and performance

- Typical chemical compositions of common alloys

- Mechanical properties

- Coating systems and layer structure

- Technical specifications

- Application fields and selection guidelines

All data are typical values for reference; exact specifications are adapted to customer requirements and applicable standards.

Prepainted aluminum sheet with thickness from 0.02 mm to 3.0 mm is produced by continuous coil coating. Bare aluminum coil is:

- Cleaned & chemically pre-treated

- Primed (front and/or back)

- Top-coated (e.g., polyester, PVDF, polyurethane, epoxy, etc.)

- Oven-cured and cooled

- Slit or cut into sheets

This controlled process offers:

- Stable color and gloss

- High corrosion and weathering resistance

- Improved scratch and abrasions resistance

- Excellent formability and easy fabrication

2. Thickness Range & Positioning

Prepainted aluminum in this range can be grouped by functional thickness:

| Sub-Range (mm) | Typical Name | Typical Use |

|---|---|---|

| 0.02–0.10 | Ultra-thin / foil-like | Interior decorative laminates, packaging |

| 0.10–0.50 | Thin sheet / strip | Ceiling, blinds, labels, lighting trims |

| 0.50–1.00 | Standard sheet | Interior panels, small appliances, signage |

| 1.00–2.00 | Structural sheet | Architectural facades, cladding, cabinets |

| 2.00–3.00 | Heavy-gauge sheet | Facade cassettes, transportation, equipment |

3. Features & Benefits

3.1 Main Features

Stable color & uniform appearance

Factory-controlled film thickness and curing provide consistent color, gloss, and texture.High corrosion resistance

Combination of Al–Mg alloy, optimized pretreatment, and primer/topcoat systems ensures good performance in industrial, coastal, and urban environments (depending on coating type).Excellent formability

Suitable for bending, roll forming, cutting, stamping and light drawing within specification limits. Coatings are flexible and resistant to cracking or peeling under proper forming radii.Lightweight with high strength-to-weight ratio

Aluminum density about 2.7 g/cm³—approx. one-third of steel, reducing structural weight and transportation cost.Good weathering and UV resistance

Especially with PVDF and high-durability polyester (HDP) systems, enabling long service life in exterior applications.Environment-friendly and recyclable

Aluminum substrate is fully recyclable; modern coatings are usually RoHS-compliant and low-VOC ready.

3.2 Benefits for Customers

| Area | Benefit | Impact |

|---|---|---|

| Fabrication | Easy cutting, bending, roll forming | Lower processing cost and tooling wear |

| Construction | No on-site painting, light weight | Shorter construction time, reduced labor |

| After-sales | Good durability & colour retention | Longer maintenance cycles, low life-cycle cost |

| Appearance | Wide color & texture options | Enhanced design flexibility |

| Logistics | Lower weight, standard coil/sheet packaging | Reduced shipping cost, easy handling |

4. Common Alloys & Chemical Composition

Prepainted aluminum is typically produced in 1xxx, 3xxx or 5xxx series alloys, depending on required strength, corrosion resistance, and forming.

4.1 Typical Alloys for 0.02–3.0 mm Sheets

- AA1050 / AA1100 – High purity, excellent formability, commonly for decorative and interior components.

- AA3003 / AA3004 / AA3105 – Mn-containing medium-strength alloys with improved corrosion resistance; widely used in building panels and interior furnishings.

- AA5005 / AA5052 – Mg-containing alloys with higher strength, superior corrosion resistance; used for building facades, transportation, marine-related installations.

4.2 Example Chemical Composition (Typical Values)

Table 1 – Chemical Composition (wt%, typical ranges)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others (each) | Al (min.) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | – | ≤0.05 | ≤0.05 | ≤0.03 | 99.50 |

| 1100 | ≤0.95* | – | 0.05–0.20 | – | – | – | ≤0.10 | – | ≤0.05 | 99.00 |

| 3003 | ≤0.60 | ≤0.70 | ≤0.20 | 1.00–1.50 | – | – | ≤0.10 | ≤0.05 | ≤0.05 | Balance Al |

| 3004 | ≤0.30 | ≤0.70 | ≤0.25 | 1.00–1.50 | 0.80–1.30 | – | ≤0.25 | ≤0.05 | ≤0.05 | Balance Al |

| 3105 | ≤0.60 | ≤0.70 | ≤0.30 | 0.30–0.80 | 0.20–0.80 | – | ≤0.40 | ≤0.10 | ≤0.05 | Balance Al |

| 5005 | ≤0.30 | ≤0.70 | ≤0.20 | ≤0.20 | 0.50–1.10 | – | ≤0.25 | ≤0.10 | ≤0.05 | Balance Al |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | 0.10 | 2.20–2.80 | 0.15–0.35 | ≤0.10 | ≤0.03 | ≤0.03 | Balance Al |

*For 1100, Si+Fe ≤0.95%.

Values are typical to major international standards (e.g., ASTM B209, EN 573); specific project values may differ within standard ranges.

5. Mechanical Properties

5.1 Typical Tempers

Common tempers for prepainted aluminum sheets:

| Temper | Description | Main Use |

|---|---|---|

| O / HO | Fully annealed, very soft | Deep drawing, complex forming |

| H14 | Half-hard, strain-hardened | General forming & bending |

| H16 / H18 | Hard / full-hard | Flat applications, minimal forming (panels) |

| H24 / H26 | Strain-hardened and partially annealed | Exterior cladding, roofing, fascia |

5.2 Typical Mechanical Properties (after coating)

Table 2 – Typical Mechanical Properties (Representative Values)

(Room temperature, for reference only)

| Alloy–Temper | Thickness (mm) | 0.2% Proof Strength Rp0.2 (MPa) | Tensile Strength Rm (MPa) | Elongation A50 (%) |

|---|---|---|---|---|

| 1050 H14 | 0.30–1.0 | 60–80 | 100–140 | 10–20 |

| 1100 H14 | 0.30–1.0 | 70–95 | 120–150 | 8–18 |

| 3003 H14 | 0.30–2.0 | 90–120 | 130–180 | 8–18 |

| 3004 H24 | 0.30–1.5 | 160–200 | 200–250 | 8–16 |

| 3105 H24 | 0.25–1.5 | 110–150 | 150–200 | 8–18 |

| 5005 H14 | 0.30–2.0 | 90–140 | 145–190 | 10–20 |

| 5052 H32 | 0.30–3.0 | 160–215 | 215–265 | 7–14 |

Forming performance also depends on coating flexibility; small bending radii are achievable with suitable systems and temper.

6. Coating Systems & Structure

Prepainted aluminum sheets are produced via coil coating line, creating a multi-layer system on front and back surfaces.

6.1 Typical Coating Stack (Front Side)

Table 3 – Typical Coating Layer Structure (Front)

| Layer | Material Example | Typical Dry Film Thickness (µm) | Main Functions |

|---|---|---|---|

| Topcoat | PE, HDP, PVDF, PU | 15–30 (up to 35–40 as required) | Color, weather resistance, UV & chemical barrier |

| Primer | Epoxy / polyester | 5–10 | Adhesion to pretreatment, corrosion resistance |

| Chromate-free Pretreatment* | Conversion coating | ~0.5–2 (conversion film) | Corrosion resistance, adhesion improvement |

| Aluminum substrate | 1050/3003/5005 etc. | Thickness 0.02–3.0 mm | Structural, mechanical, and corrosion properties |

*Modern lines generally use chromium-free systems.

6.2 Typical Backside Coating

Table 4 – Typical Backside Coating

| Backside Layer | Thickness (µm) | Role |

|---|---|---|

| Backcoat (if visible) | 8–15 | Basic corrosion resistance, color recognition |

| Service lacquer / primer | 3–8 | Adhesion, protection in non-visible zones |

7. Coating Types & Performance

7.1 Common Topcoat Types

Table 5 – Comparison of Common Coating Systems

| Type | Weather Resistance | Flexibility | Chemical Resistance | Typical Warranty (Exterior) | Common Use |

|---|---|---|---|---|---|

| PE (Polyester) | Good (standard) | Good | Medium | 10–15 years* | Interior, standard exterior |

| HDP (High-Durability Polyester) | Very good | Good–very good | High | 15–20 years* | Exterior facade, roofing |

| PVDF (70% fluorocarbon) | Excellent | Good–very good | Very high | 20–30+ years* | Premium facade, severe climates |

| PU (Polyurethane-modified) | Very good | Very good | High | 15–20 years* | Industrial, facade, roofing |

| Epoxy (usually primer/back) | Moderate–Good | Good | High (chemicals) | – | Backside, primer only |

*Indicative; depends on environment, color, thickness, and system design.

7.2 Performance Indicators

Table 6 – Typical Coating Performance Test Values

| Property / Test | Standard Example | Typical Value / Result |

|---|---|---|

| Color difference (ΔE) within batch | Internal QA | ΔE ≤ 1.0–1.5 (same coil segment) |

| Gloss (60°) tolerance | ASTM D523/EN ISO 2813 | ±5 gloss units from target value |

| Pencil hardness | ASTM D3363 | HB–2H (depending on system) |

| Adhesion (cross-hatch, dry) | ASTM D3359 | Classification 0–1 |

| Impact resistance | ASTM D2794 | 50–80 cm·kg (no cracking/peel, typical) |

| T-bend (coating flexibility) | ASTM D4145 | 0T–3T (no cracking; depends on coating) |

| Salt spray resistance (neutral) | ASTM B117 | ≥500 h to ≥2000 h (system-dependent) |

| Humidity resistance | ASTM D2247 | ≥1000 h (blister size ≤8, few) |

| UV/Weathering (QUV / natural exposure) | ASTM G154 / ISO 2810 | Gloss retention & color change as per system (PVDF > 80% gloss retention in 20+ years typical) |

8. Technical Specifications

8.1 Dimensional Range

Table 7 – Standard Dimensional Parameters

| Item | Range / Spec (Typical) |

|---|---|

| Thickness | 0.02–3.0 mm |

| Thickness tolerance | ±0.02–0.05 mm (depending on gauge & standard) |

| Width | 20–1600 mm custom (commonly 600–1250 mm) |

| Coil ID (inner diameter) | 150/300/405/508/610 mm (as ordered) |

| Coil OD (outer diameter) | Usually 1000–1600 mm (equipment-dependent) |

| Coil weight | 0.5–8.0 tons; typical 3–5 tons per coil |

| Topcoat thickness | 15–30 µm standard (up to 40 µm on request) |

| Primer thickness | 5–10 µm |

| Backcoat thickness | 5–15 µm |

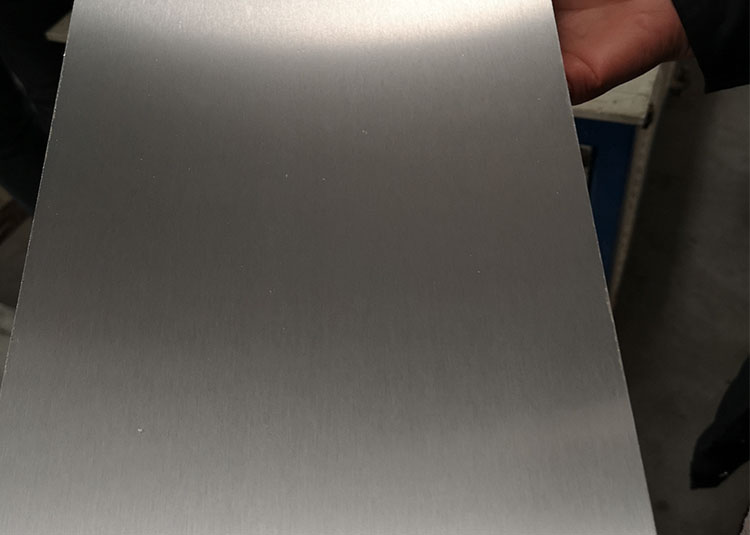

8.2 Flatness & Surface Quality

| Item | Typical Requirement |

|---|---|

| Flatness (wave height) | ≤ 1–3 mm/m depending on thickness and spec |

| Edge camber | ≤ 1–2 mm/m |

| Surface defects | No visible roll marks, dents, pinholes, large inclusions at standard viewing distance |

| Coating continuity | No bare substrate, no significant scratches or blisters |

Inspection performed according to buyer/producer agreed standards (e.g., EN 1396 or internal standards).

9. Performance Advantages vs. Alternatives

9.1 Aluminum vs. Steel (PPGI/PPGL)

| Aspect | Prepainted Aluminum | Prepainted Steel |

|---|---|---|

| Density | ~2.7 g/cm³ (light) | ~7.8 g/cm³ (heavy) |

| Corrosion resistance | Very good; better in many atmospheres | Depends heavily on zinc/aluzinc layer |

| Repair after cut edge | Generally better natural oxide | Requires careful edge protection |

| Magnetic properties | Non-magnetic | Magnetic |

| Lifecycle cost | Lower maintenance typical (facades, coastal) | Lower initial cost, higher maintenance outdoors |

10. Application Fields

Prepainted aluminum sheets in 0.02–3.0 mm thickness are widely used across many industries.

10.1 Building & Architecture

- Exterior wall cladding and facade cassette systems (1.0–3.0 mm, PVDF/HDP)

- Soffits, fascias, eaves, roof edge trims (0.5–1.2 mm)

- Standing seam roofing, roofing tiles, shingles (0.5–1.0 mm)

- Ceiling systems; baffle, clip-in, lay-in ceilings (0.3–0.7 mm)

- Gutter, downspout, flashing (0.5–1.0 mm, often 3003/3105)

- Window and door trims, curtain wall shading components

Selection example:

| Application | Recommended Thickness (mm) | Alloy | Coating Type | Notes |

|---|---|---|---|---|

| Exterior facade panel | 1.5–3.0 | 3004, 5005 | PVDF / HDP | High color stability and corrosion |

| Indoor ceiling panel | 0.4–0.7 | 1100, 3003 | PE | Interior use, non-aggressive env. |

| Roofing strip | 0.5–0.8 | 3003, 3105 | HDP / PU | Requires stain & chalking resistance |

10.2 Household Appliances & Electrical

- Front and side panels of refrigerators, freezers, washing machines (0.4–1.0 mm)

- Microwave, oven and range hood external covers (0.5–1.0 mm)

- Small home appliances: air cleaner, fan housings, coffee machines (0.4–0.8 mm)

- Electrical cabinet and distribution boxes (0.8–2.0 mm, mainly interior use)

Selection attributes:

- Good impact resistance & hardness

- Color and decorative appearance (metallic, solid color, matte, high gloss)

- Resistance to detergent, cleaning agents, mild chemicals

10.3 Transportation

- Interior panels and trims for buses, trains, metro (0.6–1.5 mm)

- Truck body panels, box panels, doors (0.8–1.5 mm)

- Caravan/motorhome/exhibition vehicle box and interior partitions

Aluminum’s light weight reduces the mass of vehicles, improving fuel efficiency or battery range (for EVs).

10.4 Packaging & Decorative

- Ultra-thin decorative sheet for blinds and louvers (0.16–0.25 mm)

- Label stock, nameplates (0.2–0.5 mm)

- Lampshades, lighting reflectors (0.3–0.8 mm, often high-gloss / white coatings)

- Honeycomb panel face sheets (0.5–1.0 mm, 3003/5052)

10.5 Industrial & Other

- HVAC ducts, ventilation ducts, air diffusers (0.5–0.8 mm)

- Clean-room panels, machine covers (0.7–1.2 mm)

- Solar frame components, shading systems, louvers

- Marine furniture, cabin walls (where good corrosion resistance is needed)

11. Design & Selection Guidelines

11.1 Choosing Alloy & Temper

Table 8 – Alloy/Temper Selection

| Requirement | Recommended Alloy & Temper |

|---|---|

| Max formability / deep drawing | 1050/1100 O or H12 |

| General building cladding | 3003/3004/3105 H14–H24 |

| Higher strength / marine influence | 5005, 5052 H14–H32 |

| Flat roofing & roll forming | 3003/3105 H24 |

Thinner gauges (<0.4 mm) usually in softer tempers for forming; thicker gauges (≥1.0 mm) may use harder tempers for panel rigidity.

11.2 Choosing Coating System

| Environment / Requirement | Recommended Coating |

|---|---|

| Interior, non-aggressive | Standard PE, epoxy-PE hybrid |

| General outdoor (suburban) | HDP or high-solid PE |

| High UV / high humidity | PVDF, high-durability PU |

| Industrial pollution exposure | PVDF or PU with strong chemicals resistance |

| Coastal / marine environment | PVDF, Al–Mg alloy (5005/5052) + robust pre-treatment |

11.3 Color & Surface Options

- Solid RAL or custom corporate colors

- Metallic effects (aluminum grain, metallic mica)

- Surface textures: smooth, embossed (orange peel, stucco), matte / low-gloss, or high-gloss

- Special systems: anti-graffiti, scratch-resistant, antibacterial and anti-fingerprint (on request)

12. Processing & Fabrication Notes

12.1 Recommended Bending & Forming

To prevent coating cracking:

| Bending Parameter | Typical Recommendation |

|---|---|

| Minimum inner bending radius | ≥ 1–1.5 × sheet thickness for normal PE coatings; larger for harder systems |

| Bending direction | Preferably perpendicular to rolling direction when feasible |

| Operating temperature | Avoid forming at very low temperatures (<5–10 °C) |

Edge protection may be needed for very aggressive environments (e.g., sealing cut edges on facade elements).

12.2 Cutting Methods

- Shearing and slitting: Standard method; ensure sharp tooling to minimize burrs and coating chipping.

- Punching: Applies primarily for hole patterns in panels and ventilated facades.

- Laser cutting: Possible but requires control to prevent local burning and discoloration of coating (often deep drawing or shearing is preferred before coating; for prepainted sheets, parameter optimization is important).

13. Quality Control & Standards

Prepainted aluminum sheets are commonly produced to comply with:

- EN 485 / EN 573 – Wrought aluminum sheets and plates

- EN 1396 – Aluminium and aluminium alloys — Coil coated sheet and strip

- ASTM B209 / B209M – Aluminum and Aluminum-Alloy Sheet and Plate

- Enterprise or project-specific specifications for:

- Color tolerances (e.g., ΔE)

- Gloss level & distribution

- Mechanical properties

- Coating thickness & adhesion

- Corrosion and weathering resistance

Regular quality control steps:

- Online coating weight/thickness measurement

- Offline cross-cut adhesion test

- Gloss and color checking (spectrophotometer)

- Salt spray and QUV accelerated weathering (periodically)

Prepainted aluminum sheet with 0.02–3.0 mm thickness delivers a combination of:

- Optimized weight and mechanical strength through appropriate alloy-temper selection

- Good weather and corrosion resistance significantly reducing repainting and maintenance

- Stable, high-quality appearance across large building and equipment surfaces

- High formability and easy processing, adaptable to numerous profile and design needs

Through fine control of alloy, dimension, coating type, color, and film thickness, customers can tailor the product precisely to their application—whether for high-end building facades, light roofing and ceilings, doors and cabinets, appliances, or vehicle body components.

https://www.al-alloy.com/a/prepainted-aluminum-sheet-with-002-3mm-thickness.html