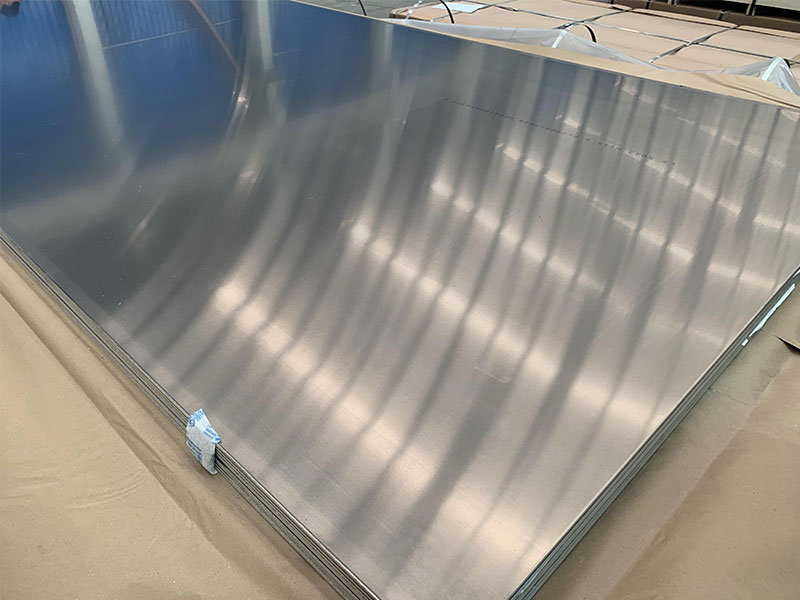

Astm Standard Marine Grade Aluminium Sheet

12/05 2025

ASTM standard marine grade aluminium sheet offers high corrosion resistance, excellent weldability, and optimal strength-to-weight ratio for shipbuilding, offshore platforms, marine structures, and coastal applications. Available in popular alloys like 5083, 5086, 5456, and 5052, it meets ASTM B928/B928M and B209 standards, ensuring reliable performance in seawater and harsh marine environments.

ASTM standard marine grade aluminium sheet is specially designed and certified for use in maritime and coastal environments. Compared with general-purpose aluminium sheet, marine grade materials are optimized for:

- Extended seawater corrosion resistance

- High strength-to-weight ratio for hull and superstructure designs

- Excellent weldability (especially with MIG/TIG welding)

- Fatigue resistance and impact toughness in dynamic wave conditions

- Compliance with leading marine classification and ASTM standards

These sheets are commonly delivered in alloy families 5000 (Al-Mg) and 6000 (Al-Mg-Si), with 5000 series being the dominant choice for direct seawater exposure.

2. Relevant ASTM Standards

2.1 Primary Standards for Marine Aluminium Sheet

| ASTM Standard | Title / Scope | Relevance to Marine Use |

|---|

| ASTM B928 / B928M | Standard Specification for High Magnesium Aluminum-Alloy Sheet and Plate for Marine Service and Similar Environments | Main standard for 5xxx marine alloys with low SCC risk |

| ASTM B209 / B209M | Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate | General spec including 5xxx and 6xxx alloys—often referenced with marine classification rules |

| ASTM B928 Annex | Additional requirements on microstructure & exfoliation corrosion | Critical to ensure long-term anti-corrosion performance |

Many classification societies (DNV, ABS, LR, BV etc.) cross-reference these ASTM standards in their own rules.

3. Marine Alloys for ASTM Sheet

While many alloys exist, the core marine grades are:

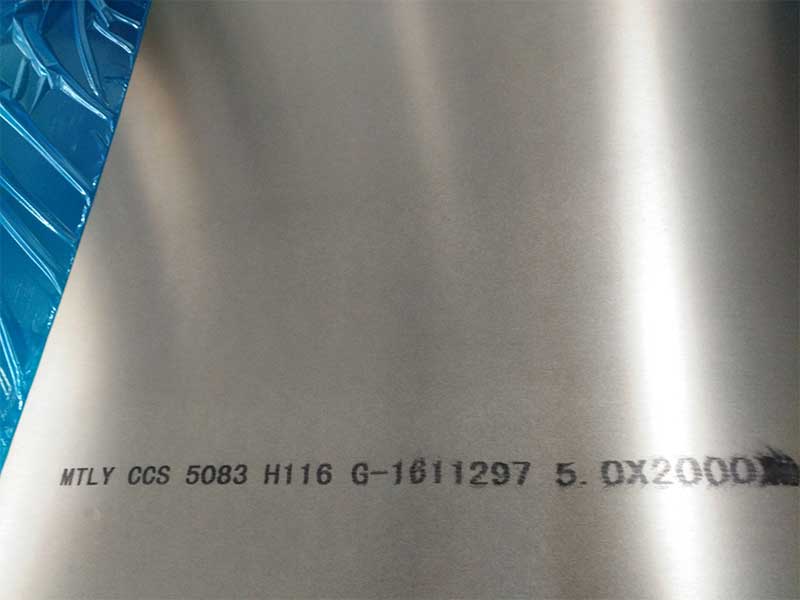

- 5083 – High strength, outstanding seawater corrosion resistance, hulls and decks

- 5086 – High strength, good toughness, very good weldability, hulls, side shell, decks

- 5456 – Higher strength than 5083/5086; typically used in heavily stressed structures

- 5052 – Good corrosion resistance, moderate strength; used for internal panels, fittings, housings

- 6061 (selected applications) – High strength 6xxx, used mainly in structural components not in constant seawater immersion

3.1 Typical Mechanical Properties (Room Temperature)

Representative values – actual mill certificates should be consulted for design

| Alloy | Temper | Thickness Range (mm) | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation (A50, %) |

|---|

| 5083 | H116 | 3.0 – 25 | 305 – 345 | ≥ 215 | ≥ 10 – 12 |

| 5083 | H321 | 3.0 – 50 | 275 – 330 | ≥ 215 | ≥ 10 – 12 |

| 5086 | H116 | 3.0 – 25 | 275 – 315 | ≥ 205 | ≥ 10 – 12 |

| 5086 | H116 | 25 – 50 | 260 – 300 | ≥ 200 | ≥ 10 |

| 5456 | H116 | 3.0 – 25 | 330 – 370 | ≥ 240 | ≥ 10 |

| 5052 | H32 | 1.0 – 6 | 215 – 265 | ≥ 160 | ≥ 7 – 10 |

4. Chemical Composition (Typical Ranges)

Below are typical ASTM composition limits for core marine alloys (mass %):

4.1 Alloy 5083

| Element | Min (%) | Max (%) |

|---|

| Mg | 4.0 | 4.9 |

| Mn | 0.4 | 1.0 |

| Cr | 0.05 | 0.25 |

| Si | – | 0.40 |

| Fe | – | 0.40 |

| Cu | – | 0.10 |

| Zn | – | 0.25 |

| Ti | – | 0.15 |

| Others (each) | – | 0.05 |

| Others (total) | – | 0.15 |

| Al (remainder) | – | Balance |

4.2 Alloy 5086

| Element | Min (%) | Max (%) |

|---|

| Mg | 3.5 | 4.5 |

| Mn | 0.20 | 0.70 |

| Cr | 0.05 | 0.25 |

| Si | – | 0.40 |

| Fe | – | 0.50 |

| Cu | – | 0.10 |

| Zn | – | 0.25 |

| Ti | – | 0.15 |

| Others (each) | – | 0.05 |

| Others (total) | – | 0.15 |

| Al (remainder) | – | Balance |

4.3 Alloy 5456

| Element | Min (%) | Max (%) |

|---|

| Mg | 4.7 | 5.5 |

| Mn | 0.5 | 1.0 |

| Cr | 0.05 | 0.20 |

| Si | – | 0.25 |

| Fe | – | 0.40 |

| Cu | – | 0.10 |

| Zn | 0.25 | 0.50 |

| Ti | – | 0.20 |

| Others (each) | – | 0.05 |

| Others (total) | – | 0.15 |

| Al (remainder) | – | Balance |

4.4 Alloy 5052

| Element | Min (%) | Max (%) |

|---|

| Mg | 2.2 | 2.8 |

| Cr | 0.15 | 0.35 |

| Si | – | 0.25 |

| Fe | – | 0.40 |

| Cu | – | 0.10 |

| Mn | – | 0.10 |

| Zn | – | 0.10 |

| Ti | – | 0.03 |

| Others (each) | – | 0.03 |

| Others (total) | – | 0.10 |

| Al (remainder) | – | Balance |

5. Features & Performance Advantages

5.1 Main Product Features

| Feature | Description / Benefit |

|---|

| High corrosion resistance | Optimized for continuous seawater and splash zone exposure; resistant to pitting, crevice and exfoliation corrosion when produced to ASTM B928 |

| Low density & high strength | ~2.66–2.70 g/cm³ density with mechanical properties suitable for weight-critical designs (vessels, high-speed crafts) |

| Excellent weldability | Compatible with MIG/TIG processes using common marine filler metals (e.g., ER5183, ER5356) |

| Good fatigue performance | Important for hull bottom, side shell, decks, and cyclic wave loading zones |

| Non-magnetic and non-sparking | Advantage in naval, offshore and special handling environments |

| Good formability & machinability | Readily formed to hull curvature, stiffeners, bulkheads, and structural profiles |

| Fire behavior | Does not propagate flames; forms an oxide layer; commonly used where fire resistance is required per marine rules (with proper insulation) |

| Long service life & low maintenance | Reduced repainting and repair frequency compared with carbon steel hulls |

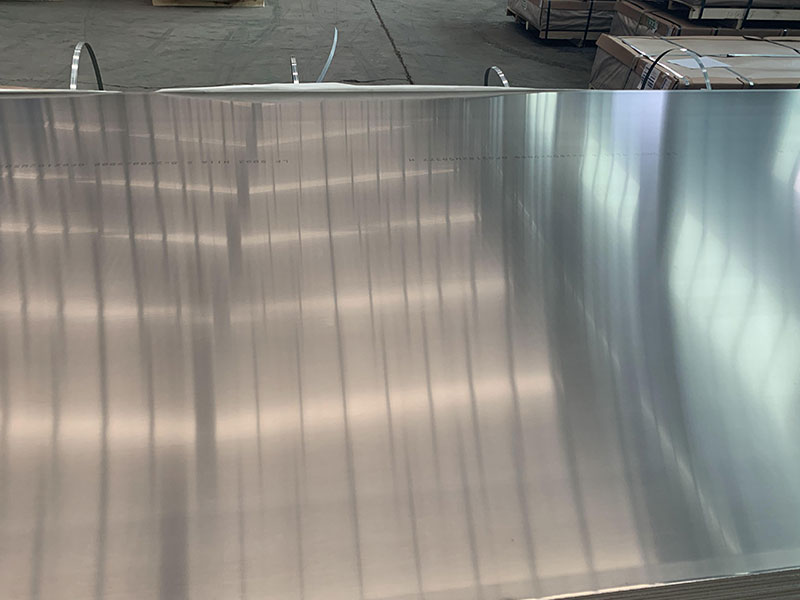

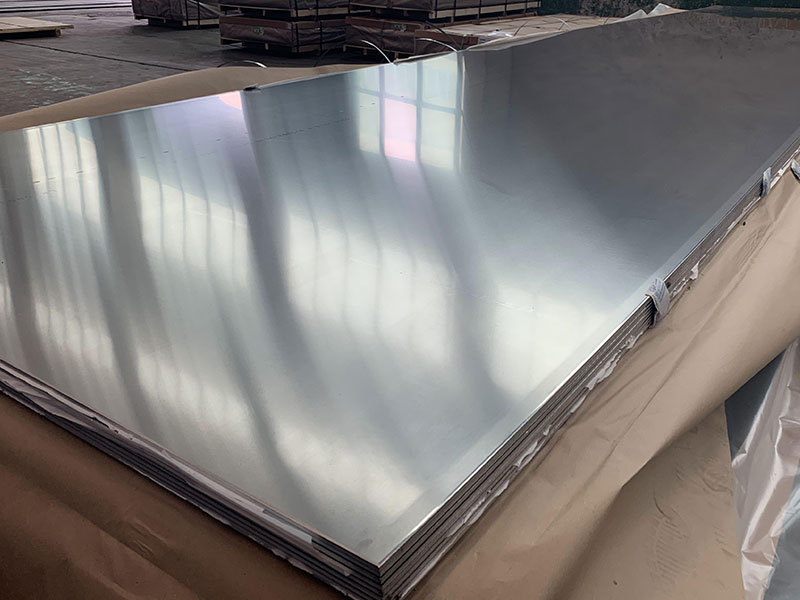

5.2 Surface & Finish Options

| Surface Condition | Description | Typical Use |

|---|

| Mill finish | As-rolled, light rolling lines | Internal structures, welded panels |

| Brushed / Ground | Mechanically finished | Visible structural parts, interiors |

| Anodized (where used) | Thickened oxide film for enhanced corrosion & aesthetics | Superstructure, exposed plates (mainly 5xxx in non-immersed zones) |

| Painted / Coated | Marine paint systems per ISO/IMO guidelines | Hulls, decks, topsides, offshore structure |

6. Typical Applications

6.1 Shipbuilding & Boatbuilding

| Ship Area / Component | Typical Alloys | Remarks |

|---|

| Hull bottom & side shell | 5083-H116, 5086-H116 | Major structural parts in constant seawater exposure |

| Decks & platforms | 5083-H321, 5086-H116 | Strength plus good slip-resistance after coating |

| Bulkheads (watertight & non-watertight) | 5083, 5052 | Used as flat plates, stiffened panels |

| Superstructures & wheelhouses | 5083, 5052, 6061 | Weight reduction improves stability & speed |

| Floors, linings, furniture | 5052-H32 | Light, corrosion-resistant interior components |

| Ramps and doors | 5083, 5086 | High load areas requiring fatigue resistance |

6.2 Offshore, Coastal & Port Infrastructure

| Application | Typical Alloys | Notes |

|---|

| Offshore platforms (walkways, helidecks, living quarters) | 5083, 5086 | Weight savings and installation ease |

| Gangways & access bridges | 5083, 6061 | Al-alloy reduces deadweight and corrosion risk |

| Harbor and ferry terminals | 5083, 5052 | Service in saline atmosphere and splash zones |

| Fender panels & protective cladding | 5083 | High corrosion resistance in exposed seaspray |

6.3 Other Marine & Coastal Uses

| Segment | Example Components |

|---|

| Aquaculture & fish farms | Cages, frames, workboat structures |

| Yacht & leisure boats | Hull plating, decks, cabins |

| Marine equipment housings | Pump enclosures, control boxes |

| Transportation & trailers in coastal regions | Boat trailers, tankers, cargo bodies |

7. Temper Designations & Conditions

Marine sheets are supplied in specific tempers to ensure appropriate mechanical properties and stress-corrosion resistance:

| Temper | Applicable Alloys | Description | Typical Use |

|---|

| O | 5xxx, 6xxx | Annealed, lowest strength, max ductility | Deep drawing, heavy forming |

| H111 | 5xxx | Slightly strain-hardened | General structural plates |

| H116 | 5xxx | Specially strain-hardened, controlled mechanical & SCC resistance | Hull plating, high-load plates |

| H321 | 5xxx | Strain-hardened and thermally stabilized | Decks, bottom, and side shell |

| H32/H34 | 5052 | Half- to ¾-hard strain-hardened | Formed and welded components |

| T6 | 6xxx | Solution heat-treated and artificially aged | Non-immersed structural components |

For critical hull components, H116 and H321 tempers per ASTM B928 are typically preferred.

8. Technical Specifications

8.1 Size Range & Dimensional Tolerances

Specific size availability depends on mill capability, but a typical production range:

| Parameter | Typical Range |

|---|

| Thickness (sheet) | 1.0 – 6.0 mm |

| Thickness (plate) | >6.0 – 50 mm or more |

| Width | 1000 – 2500 mm (custom up to ~3000) |

| Length | 2000 – 12000 mm (custom on request) |

8.2 Dimensional Tolerances (Indicative)

Values vary with standard and thickness; always refer to supplier data.

| Thickness (mm) | Thickness Tolerance (± mm) | Flatness (mm/m, typical) |

|---|

| 1.0 – 3.0 | 0.05 – 0.10 | ≤ 3.0 |

| 3.0 – 6.0 | 0.08 – 0.15 | ≤ 3.0 |

| 6.0 – 12 | 0.20 – 0.30 | ≤ 2.5 |

| 12 – 25 | 0.25 – 0.40 | ≤ 2.0 |

9. Physical and Thermal Properties

9.1 Typical Physical Properties

| Property | 5xxx Marine Alloys (approx.) |

|---|

| Density | 2.66 – 2.70 g/cm³ |

| Melting range | 570 – 640 °C |

| Modulus of elasticity E | ~70 GPa |

| Poisson’s ratio ν | ~0.33 |

| Coefficient of thermal expansion (20–100 °C) | ~23–25 × 10⁻⁶ /K |

| Electrical conductivity | ~28–32 % IACS |

| Thermal conductivity | 110 – 130 W/m·K |

10. Welding, Fabrication & Joining

10.1 Weldability

| Aspect | Notes |

|---|

| Welding processes | GMAW (MIG), GTAW (TIG), friction stir welding (FSW) frequently used |

| Common filler wires | ER5183, ER5356 (compatible Mg levels and corrosion behavior) |

| Preheat requirement | Generally not required; limit interpass temperature for consistency |

| Post-weld heat treatment | Not usually applied for 5xxx; mechanical properties mainly from cold work |

10.2 Forming & Bending

| Property | 5083 / 5086 | 5052 |

|---|

| Bendability | Good in O / H111 / H321 | Excellent in O / H32 |

| Minimum bend radius* | 1 – 3 × t (depends on direction & temper) | 0.5 – 2 × t |

* t = thickness; exact values depend on alloy, temper, and rolling direction.

11. Corrosion Resistance & Service Life

Marine grade aluminium sheets under ASTM B928 are engineered to mitigate:

- General and localized corrosion in seawater

- Exfoliation corrosion (through controlled microstructure and composition)

- Stress corrosion cracking (SCC) risk (important in high-Mg alloys)

Enhancements often applied:

| Protection Method | Purpose |

|---|

| Proper surface cleaning prior to coating | Ensures adhesion, reduces defects |

| Epoxy or polyurethane marine coatings | Extends service life, color & aesthetics |

| Cathodic protection (where applicable) | Extra safety on submerged sections |

| Correct alloy pairing in joints | Reduces galvanic potential and corrosion |

12. Quality Assurance & Certification

Marine-grade sheets are typically supplied with:

| Document / Test | Content |

|---|

| Mill Test Certificate (MTC) | Chemical analysis, mechanical properties, standards compliance |

| Ultrasonic testing (UT) | Verification of internal soundness for thicker plates |

| Bending & flattening tests | Verification of ductility and formability |

| Corrosion test (e.g., exfoliation) | For ASTM B928 compliance where applicable |

| Class certification (optional) | DNV, ABS, LR, BV or other society stamp as required |

13. Selection Guide – Choosing the Right Alloy

| Design Requirement | Recommended Alloy / Temper |

|---|

| Maximum corrosion resistance under immersion | 5083-H116, 5086-H116, 5456-H116 |

| High strength hull structures vs. mild steel replacement | 5083-H321, 5086-H116 |

| Light internal panels and non-immersed parts | 5052-H32 |

| Complex formed parts with good appearance | 5052-O / H32 |

| Structural members not continuously immersed, requiring machining or threading | 6061-T6 (with caution in seabed exposure and adequate protection) |

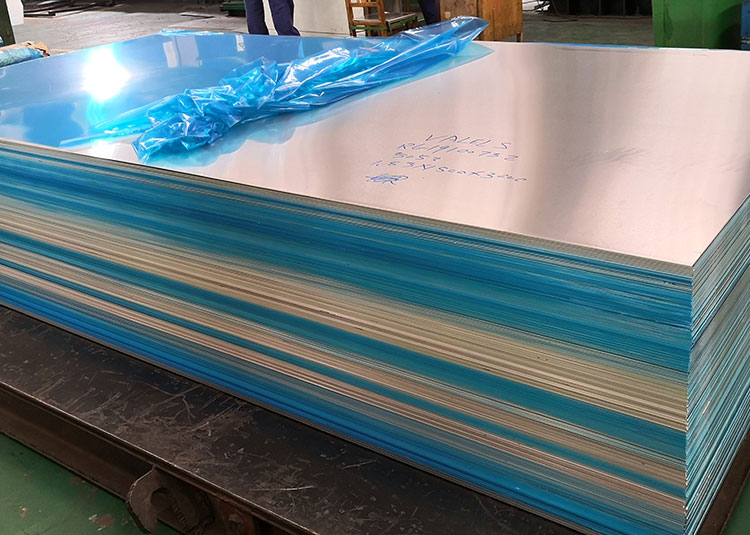

14. Packaging, Handling & Storage

| Aspect | Practice |

|---|

| Packaging | Poly-wrapped, interleaved with paper or plastic films, strapped to wooden pallets |

| Edge protection | Plastic or cardboard edge strips to prevent damage |

| Handling | Use soft slings / vacuum lifters; avoid sharp forks, point loading |

| Storage | Dry, ventilated area; avoid prolonged contact with moisture & chlorides; store off ground with spacers |

https://www.al-alloy.com/a/astm-standard-marine-grade-aluminium-sheet.html