Aluminum plate grades

When it comes to aluminum plates, there’s no one-size-fits-all. Think of aluminum plates like coffee beans—each grade has its own flavor, perfect for different tastes and purposes. To put it simply, an aluminum plate grade is a way of categorizing the metal based on its composition and properties. These tiny differences in the recipe change what the plate can do, how strong it is, how well it resists rust, and even how easy it is to work with. these grades isn’t just for engineers; it helps you pick the right material for your projects — whether you're building a boat, fabricating car parts, or crafting sleek architectural panels.

The Basics: What Are Aluminum Plate Grades?

Aluminum alloys are split into two major families: 1xxx-series, which is essentially pure aluminum, and the rest like 2xxx, 5xxx, 6xxx, and 7xxx, which mix in other metals like copper, magnesium, silicon, and zinc. These “grades” come from these alloys combined with different heat treatments or tempers, changing how tough, bendy, or corrosion-resistant the plate is.

Breaking It Down: What Do Different Grades Do?

1xxx Series (Pure Aluminum): Think of this as the vanilla base. It's soft and highly corrosion-resistant, so it’s great for chemical or food-processing industries. Not the strongest out there, but it’s super workable and won’t rust—the go-to for when durability takes a backseat to cleanliness and flexibility.

2xxx Series (Aluminum-Copper): These guys are the muscle, often the strongest and used where weight-saving matters—like in aircraft. However, they’re a bit like that strong but sensitive friend—they don’t tolerate moisture or salty conditions well, leading to corrosion issues.

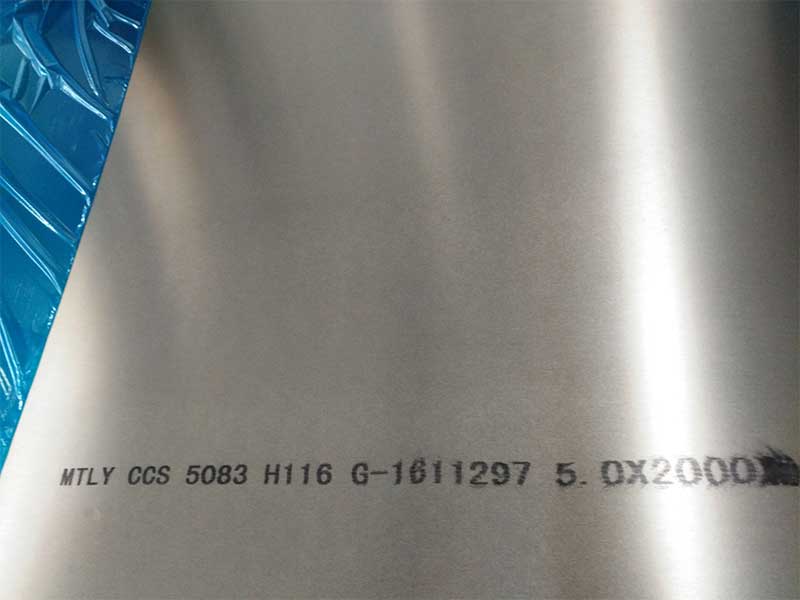

5xxx Series (Aluminum-Magnesium): A strong contender for marine environments. Imagine the rugged outdoorsman – tough, resistant to rust and fatigue, ideal for boats, trailers, and tanks where saltwater exposure is a daily test.

6xxx Series (Aluminum-Magnesium-Silicon): The multitasker appliance. Good strength and excellent corrosion resistance make this grade perfect for architectural structures, automotive parts, and even some aerospace uses requiring moderate strength with formability.

7xxx Series (Aluminum-Zinc): The ultimate powerhouse champions of high strength in the aluminum world, usually hanging out in high-tech aerospace frames. But their tendency to corrode makes them less suited to wet environments without protective coatings.

How Does Knowing Grades Help You?

Picking the right aluminum grade avoids surprises down the road. Got a project needing bending and shaping? Choosing 1xxx or 6xxx series will Save you headaches. Building a boat? Jump on the 5xxx series bandwagon for peace of mind. Aerospace applications? Look closely at strength thresholds, and 7xxx or 2xxx grades will be your friends under the hood.

A Closer Look at Technical Features

Every aluminum plate grade tells a story in numbers—yield strength (how much force before it deforms), tensile strength (how much pulling-before-it-snaps strength it has), elongation (how much it stretches before breaking), and corrosion resistance habits.

Take the popular 6061-T6 (a 6xxx series), for example. It strikes a neat balance: reasonably strong (~45,000 psi tensile strength), corrosion-resistant, weldable, and formable. That’s why you see it everywhere—from bike frames to highway guardrails.

On the flip side, 2024-T3 (a 2xxx grade) is tougher and less corrosion-friendly, shining in aerospace frames where weight and strength out-rank rust because those parts are carefully maintained.

Wrapping It Up

Aluminum plates aren’t just flat, shiny sheets. They’re versatile materials, shaped by the tiny variations in grade that give them life in different roles. Learning a bit about aluminum plate grades isn’t rocket science—it’s just picking ingredients that work for your recipe. Whether your job needs flexibility, strength, or rust-resistance, there’s a grade ready to step up.

So next time you’re staring at a stack of aluminum plates, don’t see just metal—see a toolbox full of options, each grade sharing a unique skill set just waiting for its job. That’s the beauty—and the power—of aluminum plate grades.