Polished customized thickness aluminum plate 10 mm

12/11 2025

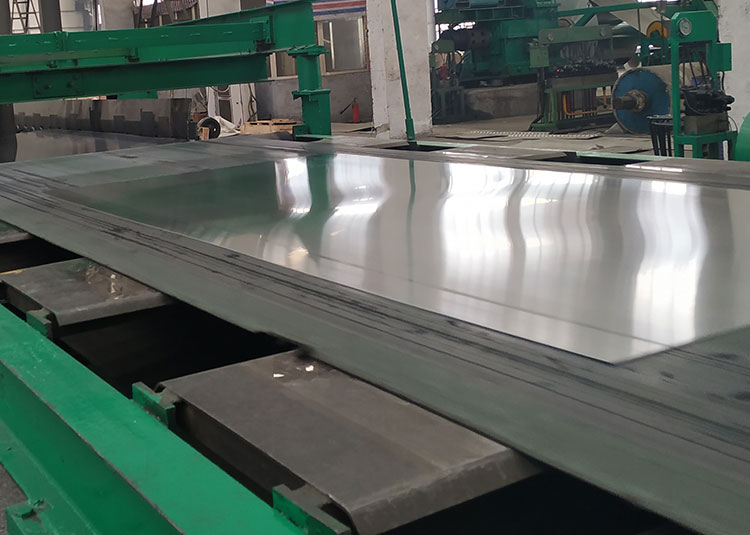

The polished customized thickness aluminum plate 10 mm is a versatile, high‑quality aluminum product designed for applications that require both excellent surface finish and stable mechanical performance. It is commonly produced from popular alloys such as 1050 / 1060 / 3003 / 5052 / 6061, depending on the customer’s strength and corrosion‑resistance requirements.

1. Features

- Precise thickness: 10 mm (other thicknesses customizable)

- Polished surface: Bright, smooth, and visually attractive

- Excellent flatness and dimensional stability

- Good corrosion resistance (especially 5xxx/6xxx series)

- Low density & lightweight compared with steel

- Good machinability and formability

- Available in multiple alloys and tempers

- Custom cutting & size according to drawings

2. Typical Available Alloys

| Alloy Series | Common Grade | Main Feature | Typical Use |

|---|

| 1xxx | 1050 / 1060 | Very high purity, soft, highly workable | Decoration, signage, reflectors |

| 3xxx | 3003 | Better strength, good corrosion | HVAC, panels, architectural parts |

| 5xxx | 5052 | Strong, excellent corrosion | Marine, transportation, cabinets |

| 6xxx | 6061 | High strength, heat‑treatable | Structural parts, frames, tooling |

Specific alloy is chosen based on required strength, corrosion resistance, and forming or machining needs.

3. Chemical Composition (Typical)**

Below is a typical reference for widely used alloy options (wt.%). Actual composition follows the relevant standards (e.g., ASTM, EN, GB) and customer requirements.

3.1 Alloy 1050

| Element | Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

|---|

| % max | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.07 | 0.05 | Balance |

3.2 Alloy 3003

| Element | Si | Fe | Cu | Mn | Mg | Zn | Others | Al |

|---|

| % max | 0.60 | 0.70 | 0.05–0.20 | 1.0–1.5 | 0.05 | 0.10 | 0.15 | Balance |

3.3 Alloy 5052

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Al |

|---|

| % max | 0.25 | 0.40 | 0.10 | 0.10 | 2.2–2.8 | 0.15–0.35 | 0.10 | Balance |

3.4 Alloy 6061

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|

| % max | 0.4–0.8 | 0.70 | 0.15–0.40 | 0.15 | 0.8–1.2 | 0.04–0.35 | 0.25 | 0.15 | Balance |

4. Dimensions & Tolerances

| Parameter | Typical Range / Value |

|---|

| Thickness | 10 mm (customizable from ~1–200 mm) |

| Width | 500–2,500 mm (or as per order) |

| Length | 500–12,000 mm (fixed length / cut‑to‑size) |

| Thickness Tolerance | ±0.10–0.20 mm (depending on standard) |

| Flatness | As per EN / ASTM; improved by leveling |

| Edge Type | Mill edge, saw‑cut, or machined edge |

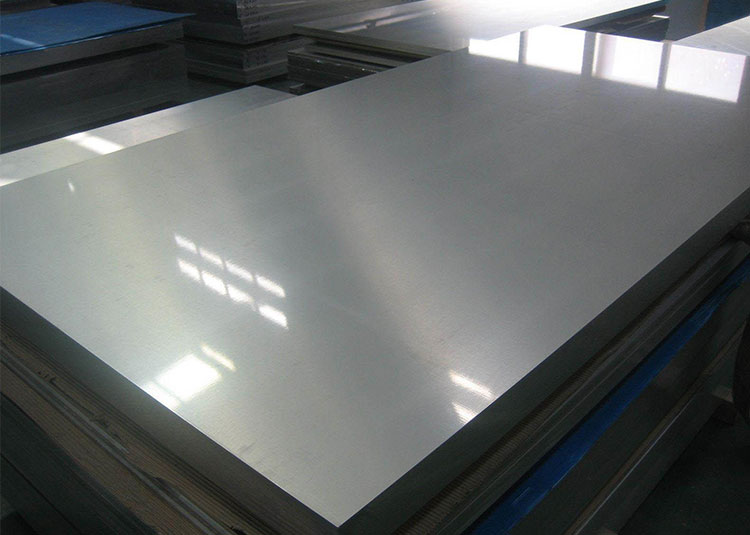

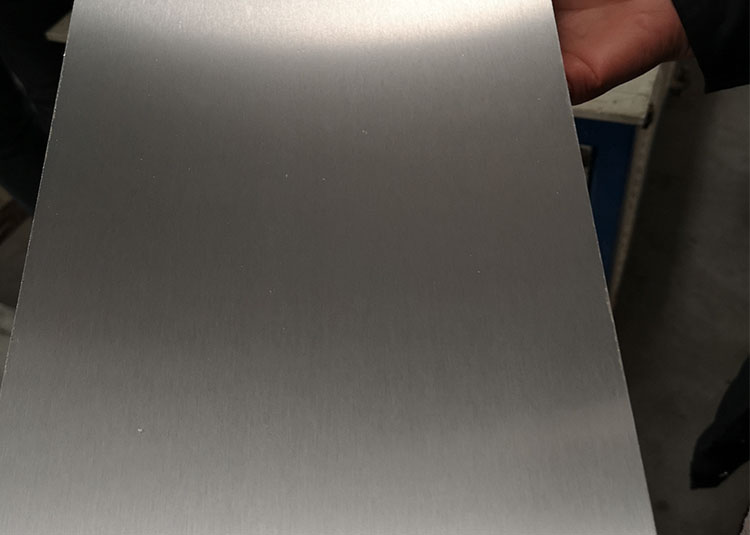

5. Surface Finish & Options

The plate is delivered with a polished surface; additional options are available:

| Surface Option | Description | Typical Use |

|---|

| Mechanical polished (bright) | Smooth reflective finish | Decorative panels, display, interior design |

| Brushed / hairline | Linear texture | Architectural cladding, appliances, signage |

| Mirror‑like polish* | High reflectance, near‑mirror | Lighting reflectors, aesthetic applications |

| Protective PE film | One or both sides | Protect against scratches during transport & process |

*Mirror level depends on alloy, base plate quality, and polishing process.

6. Mechanical Properties (Reference Values)

Properties vary with alloy and temper. Below are typical values for common choices at room temperature (not guaranteed; final data per test certificate).

| Alloy & Temper | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation A50 (%) |

|---|

| 1050 H14 | 110–145 | 95–120 | 3–8 |

| 3003 H14 | 145–195 | 115–160 | 2–10 |

| 5052 H32 | 215–265 | ≥ 160 | 7–12 |

| 6061 T6 | 260–310 | ≥ 240 | 8–12 |

7. Physical Properties

| Property | Typical Value |

|---|

| Density | ~2.70 g/cm³ |

| Melting Range | ~580–660 °C (depending on alloy) |

| Thermal Conductivity | ~120–180 W/m·K |

| Electrical Conductivity | ~35–60 % IACS (high for 1xxx series) |

| Coefficient of Expansion | ~23–24 × 10⁻⁶ /K (20–100 °C) |

8. Processability

| Operation | Performance | Notes |

|---|

| Cutting | Excellent (sawing, shearing, CNC cutting) | Suitable for custom shapes and profiles |

| Bending | Good (better with 1xxx/3xxx/5xxx soft tempers) | 6061‑T6 requires larger bending radius |

| Welding | Good, especially for 5xxx series | TIG/MIG commonly used |

| Machining | Good (6061 best; 1xxx softer for high‑precision) | Use proper coolant and tools |

| Surface treat | Anodizing, painting, powder coating possible | Polished base improves final appearance |

9. Main Advantages for Customers

| Advantage | Customer Benefit |

|---|

| Polished, attractive surface | Ready for visible applications without heavy re‑finishing |

| Stable 10 mm thickness | Easy design calculation and structural reliability |

| Custom size & alloy | Reduces scrap and secondary cutting costs |

| Lightweight yet strong | Easier handling, reduced transport weight |

| Good corrosion resistance | Longer service life, lower maintenance |

| Easy to process | Compatible with common machining/welding equipment |

10. Typical Applications

10.1 Construction & Architecture

| Application | Reason for Use |

|---|

| Wall cladding panels | Light, corrosion‑resistant, decorative |

| Interior decorative panels | Smooth polished finish, easy cleaning |

| Stair, balcony panels | Strong yet light, can be anodized/painted |

| Ceiling elements | Low weight, good flatness |

10.2 Transportation

| Application | Reason for Use |

|---|

| Vehicle flooring | 10 mm thickness gives stiffness & durability |

| Truck sideboards | Corrosion resistance, weight reduction |

| Ship interior panels | 5052 grade resists marine environments |

10.3 Machinery & Industrial Use

| Application | Reason for Use |

|---|

| Machine base plates | Flat, stable, easy to machine |

| Jigs & fixtures | 6061‑T6 provides strength and machinability |

| Control cabinets panels | Corrosion‑resistant, good appearance |

| Equipment covers & doors | Polished surface, acceptable strength |

10.4 Advertising & Decoration

| Application | Reason for Use |

|---|

| Sign boards | Smooth surface for printing & film lamination |

| Display stands | Attractive surface, customizable shapes |

| Retail decoration | Polished, modern metallic appearance |

11. Packaging & Delivery

| Item | Description |

|---|

| Surface Protection | PE film, paper interleaving as required |

| Edge Protection | Corner protectors, protective wrapping |

| Bundling | Steel or plastic straps, palletized |

| Documentation | Mill test certificate, packing list, CO |

| Lead Time | Based on quantity, alloy, and processing |

12. Ordering Information

When inquiring or ordering polished customized thickness aluminum plate 10 mm, please provide:

| Required Information | Example |

|---|

| Alloy & temper | 6061‑T6, 5052‑H32, 3003‑H14, etc. |

| Thickness | 10 mm |

| Width × Length | e.g., 1500 mm × 3000 mm |

| Surface requirement | Polished one side / both sides; brushed, etc. |

| Tolerance & standard | ASTM / EN / GB; normal or special tolerance |

| Quantity | Number of sheets / total metric tons |

| Further processing | Cutting, CNC machining, bending, drilling |

By clearly defining your requirements, we can supply the most suitable 10 mm polished aluminum plate with stable quality, efficient delivery, and optimal cost performance.

https://www.al-alloy.com/a/polished-customized-thickness-aluminum-plate-10-mm.html

Related Products

Related Blog