Aluminum Foil for Drug Blister

When you pop a pill out of its blister pack, have you ever paused to think about that thin, shiny foil backing? That’s aluminum foil, playing a crucial role you might overlook.

Why Aluminum Foil? More Than Just a Pretty Face

At first glance, aluminum foil might seem simple and straightforward. But its technical features make it a superstar in protecting medicines:

- Barrier Power: Aluminum foil acts as a superb barrier against moisture, oxygen, and light—enemies of drug stability. This means medicines stay fresh, effective, and safe during storage and transport.

- Flexibility and Strength: It’s thin enough to be pressed into the right shape for blister packs but strong enough not to tear or puncture easily. This durability is because it keeps contaminants out and protects each dose.

- Non-Toxic and Safe: Since it's chemically inert, aluminum foil won’t react with drugs. This is critical because, in the world of pharmaceuticals, keeping medicine uncontaminated is a must.

- Easy to Break but Secure: The foil is designed for a delicate balance: strong enough to secure the medicine, yet easy enough for you to peel or push through when it’s pill time.

A Closer Look: Features That Matter in Aluminum Foil

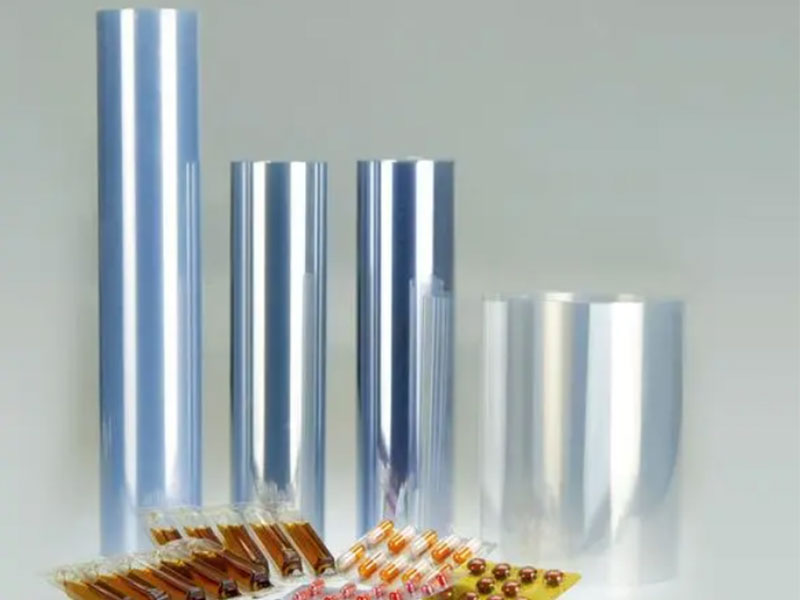

What makes aluminum foil for drug blister packs particularly unique is its exact composition and layering. It usually incorporates:

- Pure Aluminum Layer: Provides that excellent protection and flexibility.

- Coating or Lacquer: Sometimes, an extra coating is applied on the back to offer resistance against corrosion and enhance compatibility with printing or adhesion during manufacturing.

Advanced foil grades are carefully tailored to meet the strict hygiene and quality standards of the pharmaceutical industry, ensuring everything is safe for end-users.

Where and How is It Used?

You’ll find aluminum foil underpinning virtually all blister packs—from your everyday vitamins to critical prescription meds. It shines in applications where:

- Long Shelf Life is needed, particularly for sensitive formulations like antibiotics.

- Dose Precision is vital; individual pockets of the blister keep doses separate, fresh, and tamper-evident.

- Patient Convenience is considered: the foil helps designing easy-to-open yet intact packaging.

Pharmaceutical companies love aluminum foil for addressing these needs efficiently and cost-effectively.

Why Should Customers Care?

the vital role of aluminum foil in drug blister packaging makes it clear: next time you take a pill, that shine isn’t just for show. It’s a carefully engineered shield ensuring every dose you take is just as potent and safe as the day it was made.

Whether you're a pharma professional, a pharmacist, or just someone curious about what keeps your medicine safe, appreciating this foil’s technical brilliance helps you see medicine packaging in a whole new light.

In a Nutshell

Aluminum foil is the quiet guardian in drug blister packs. It combines high-tech barrier capabilities, chemical safety, physical strength, and user-friendly features—making it the perfect partner in safeguarding your medicine from factory to finger.

So next time you peel back that foil, remember: you’re unveiling a tiny masterpiece of material science, designed with your health in mind.

https://www.al-alloy.com/a/aluminum-foil-for-drug-blister.html