5083 5056 6003 6001 alloy Aluminum Sheet

Choosing between 5083, 5056, 6003 and 6001 aluminum sheet is rarely just about a datasheet comparison. In real projects, the decision is a negotiation between corrosion risk, forming behavior, welding strategy, fatigue life, surface appearance and even downstream coating or anodizing. Looking at these alloys side by side reveals four distinct personalities that solve very different engineering problems—especially once temper, microstructure and environment are considered together.

Four alloys, two families: 5xxx vs. 6xxx

All four designations fall into two core metallurgical families:

- 5083 and 5056 are Mg-based, non-heat-treatable 5xxx series alloys. Their strength arises from solid-solution strengthening of magnesium in aluminum, further boosted by cold work.

This fundamental difference explains much of the contrast in performance: weld behavior, response to elevated temperatures, paint-bake hardening potential, and stress-corrosion tendencies.

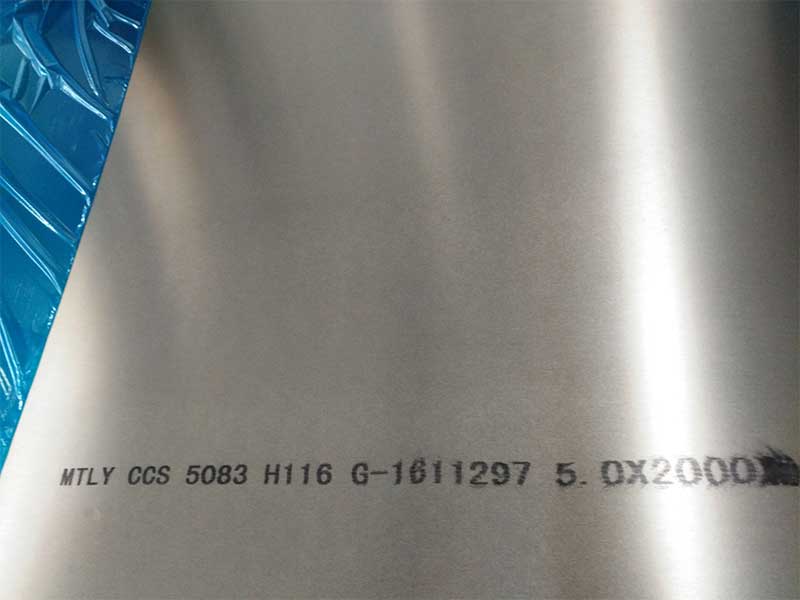

5083 Aluminum Sheet: Marine workhorse with structural ambition

Within the 5xxx family, 5083 is recognized as a high-magnesium, high-strength sheet alloy engineered for demanding environments, especially where seawater, salt spray or aggressive industrial atmospheres are unavoidable.

Typical chemical composition range for 5083 (mass percent, reference values):

- Magnesium: about 4.0–4.9

- Manganese: about 0.4–1.0

- Chromium: about 0.05–0.25

- Iron + Silicon: each typically below about 0.4

- Copper: usually below about 0.1 to protect corrosion resistance

- Remaining: aluminum and trace elements

The high magnesium content gives 5083 its structural capability without heat treatment. In H116 or H321 tempers, 5083 sheet exhibits high yield strength combined with excellent resistance to stress corrosion cracking in marine and chloride environments. Chromium and manganese refine the grain structure and stabilize corrosion behavior over time.

From a processing standpoint, 5083 is designed to be welded. Fusion welding by MIG or TIG produces joints that, while somewhat softer than the base material due to localized annealing, still retain adequate strength and corrosion performance. This is crucial for ship hulls, deck structures, LNG tanks, vehicle bodies and pressure-retaining cold storage units.

Because 5083’s strength depends on cold work rather than precipitates, exposure to elevated temperatures above about 65–70 °C for long periods can slowly relax strain hardening and reduce strength. This makes it ideal for cryogenic tanks and marine structures but less suitable for prolonged high-temperature service.

Applications where 5083 sheet tends to be the default choice include:

- Marine hull plating, superstructures and decks

- Offshore platform components and splash-zone structures

- LNG and low-temperature storage tanks

- High-strength, corrosion-resistant vehicle bodies and semi-trailers

Where designers want a structural sheet that can live in saltwater and survive decades of cyclic loading and welding, 5083 offers a well-known, well-characterized solution.

5056 Aluminum Sheet: Specialist in corrosion-critical joining and fasteners

5056 sits close to 5083 chemically but with its own optimization. It was traditionally developed to address demanding needs for rivets, fasteners and wire in corrosive environments, especially for joining magnesium-rich alloys or aluminum-magnesium structures.

Reference chemical composition for 5056 (mass percent, typical):

- Magnesium: about 4.5–5.6

- Manganese: up to about 0.3

- Chromium: up to about 0.3

- Iron + Silicon: generally low, typically below about 0.4

- Copper: very low, often below about 0.1

- Remaining: aluminum and trace elements

The slightly higher magnesium range compared to 5083 increases achievable strength in heavily cold-worked tempers, which is particularly useful for rivet wire and mechanical joining elements that must endure setting forces and long-term fatigue.

As sheet, 5056 is more of a niche but very valuable material. It is favored where galvanic relationships, rivet corrosion or joint life dominate the design envelope. For example, in marine and aircraft applications where a mismatch between fastener and sheet alloy can drive local pitting, 5056 provides a more compatible, corrosion-resistant joint material with surrounding 5xxx alloys and some magnesium alloys.

Its role in sheet form can be seen in:

- Corrosion-resistant cladding or liner sheets in combination with 2xxx or 7xxx structural alloys

- Specialized marine panels where both base sheet and joining elements are tailored as a system

- Components where later cold working is expected (deep drawing, complex bending) while keeping strong corrosion performance

Compared to 5083, 5056 is less prominent as a primary structural plate but more critical as a complementary material where joining, compatibility and galvanic balance are the main design drivers.

6003 Aluminum Sheet: Hidden performer in architecture and automotive trim

Moving to the 6xxx family changes the design philosophy. Here, Mg and Si are balanced to form the strengthening phase Mg₂Si through controlled solution heat treatment and aging.

6003 is a less publicized but technically interesting variant, tuned for good extrudability, moderate strength and excellent surface finish. While better known in extruded profiles, sheet products are increasingly used where:

- Anodizing appearance matters

- Medium strength is acceptable

- Formability and bendability must remain robust in thin gauges

A typical 6003 chemistry (mass percent, indicative):

- Magnesium: about 0.4–0.7

- Silicon: about 0.5–1.0

- Manganese: up to about 0.5

- Iron: typically below about 0.35

- Copper: usually very low, often below about 0.1

- Chromium and other modifiers: small additions as required

- Remaining: aluminum and trace elements

The moderate Mg and Si levels, combined with low copper, help 6003 maintain good corrosion resistance and a clean anodized finish. In T5 or T6 tempers, 6003 sheet can achieve yield strength suitably above standard building alloys like 6060 while still forming reliably in press-brake operations.

From a processing standpoint, 6003 belongs to the heat-treatable family, so its strength is tunable. Solution treatment followed by artificial aging generates a fine Mg₂Si precipitate structure that gives higher hardness and yield strength. In a paint-bake process, automotive panels may be supplied in a partly aged temper and then reach final properties during the customer’s coating bake.

Typical application fields for 6003 sheet include:

- Architectural cladding panels where anodized color consistency is critical

- Door and window framing sheet parts used with extruded sections of the same alloy family

- Automotive exterior trim and interior structural panels that benefit from paint-bake hardening

- Light structural components where a balance of surface finish, moderate strength and formability is desired

In essence, 6003 sheet fills the space between aesthetic-critical and strength-conscious design, marrying appearance and mechanical performance.

6001 Aluminum Sheet: Structural intent in the 6xxx sheet family

If 6003 is tuned for surface and formability, 6001 leans more structural within the same alloy family. It is often positioned as a medium-strength, good-weldability alternative to more widely known 6061, particularly in sheet and extrusion where certain processing advantages or specific temper responses are desired.

Indicative chemistry for 6001 (mass percent, typical):

- Magnesium: about 0.6–1.0

- Silicon: about 0.7–1.3

- Manganese: up to about 0.5

- Iron: typically below about 0.4

- Copper: generally low, often below about 0.15

- Chromium and other elements: small controlled additions

- Remaining: aluminum and trace elements

Compared with 6003, 6001 generally targets a slightly higher strength window through its Mg and Si levels, making it suitable for load-bearing frames and structural subcomponents. In T6 temper, 6001 sheet reaches higher yield and tensile strengths while maintaining good toughness and weld behavior.

Heat treatment is again central. Solution heat treatment across the Mg₂Si solvus, followed by rapid quenching and aging, produces a dense, fine precipitate structure that contributes to:

- High yield strength and stiffness

- Good fatigue resistance for structural members

- Predictable response to paint-bake cycles

6001 sheet is often chosen in systems thinking: it pairs naturally with 6001 or 6xxx extrusions in vehicle frames, trailers, building structures and industrial platforms. When welding, the heat-affected zone will soften compared with the T6 base material, a fundamental characteristic of 6xxx alloys, but the overall structural capacity often remains adequate with proper joint design.

Applications where 6001 sheet is particularly valuable include:

- Lightweight structural panels in vehicle or rail car bodies

- Load-bearing architectural elements and truss components

- Industrial platforms, walkways and machine frames requiring corrosion resistance and medium to high strength

- Integrated systems where sheet and extrusions share the same alloy for consistent weldability and mechanical behavior

Rather than asking which alloy is “best,” it is more productive to ask what system you are designing.

For saltwater-dominated structures and cryogenic tanks, the non-heat-treatable 5xxx alloys—with their solid-solution Mg strengthening and inherent resistance to stress corrosion cracking—take precedence. Here 5083 is the structural mainstay, while 5056 complements it as a specialist for corrosion-compatible fasteners, rivets and claddings.

Where surface finish, paint-bake response and controlled aging are vital—such as automotive body panels, architectural façades or refined interior structures—the 6xxx family enters. 6003 offers a harmonized balance of appearance and moderate strength; 6001 nudges toward higher structural performance while retaining 6xxx’s hallmark weldability and precipitation-hardening flexibility.

The real distinction emerges when you integrate temper selection, fabrication route and service environment:

- 5xxx sheet (5083, 5056) gains strength by cold work, loses it slowly with prolonged heat, and excels in chloride-rich service.

- 6xxx sheet (6003, 6001) gains strength by heat treatment, softens in the weld zone, and offers superior synergy with coating, anodizing and paint-bake processes.

Seen from this perspective, 5083, 5056, 6003 and 6001 are not competitors but coordinated tools. The optimal choice is not simply a matter of maximum strength or corrosion rating but of matching metallurgical mechanism to the real-world life of the component—from rolling mill, through forming and welding, all the way to decades in service.

https://www.al-alloy.com/a/5083-5056-6003-6001-alloy-aluminum-sheet.html