Embossed aluminum circle sheet

Embossed aluminum circle sheet is a lightweight, non-slip and decorative aluminum disc widely used for cookware, lighting reflectors, traffic signs and decorative panels. Available in alloys like 1050, 1060, 1100, 3003 and 5052, it offers excellent formability, corrosion resistance, and a patterned surface that enhances appearance and performance in both household and industrial applications.

What Is Embossed Aluminum Circle Sheet?

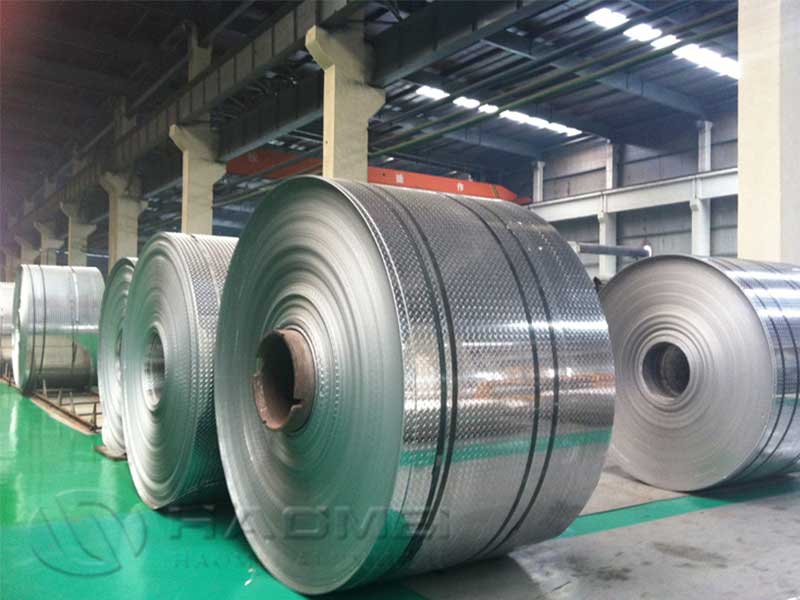

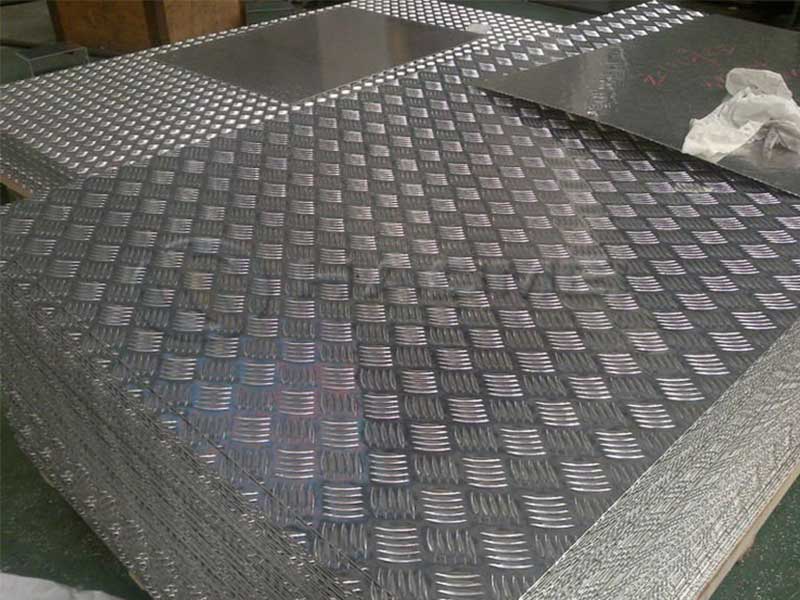

Embossed aluminum circle sheet is a round aluminum blank with a textured surface produced by passing aluminum coil through patterned rollers. Instead of a flat, smooth disc, the surface displays a regular raised pattern (such as stucco, orange peel, or hammer finish).

These textured aluminum circles combine the forming advantages of standard aluminum discs with improved grip, scratch masking, and decorative appeal. They are supplied in various diameters and thicknesses, ready for deep drawing, spinning, pressing, or stamping.

Features and Advantages

- Embossed surface improves grip, reduces slip, and hides minor scratches

- Excellent formability suitable for deep drawing and spinning processes

- Good corrosion resistance in both indoor and outdoor environments

- Attractive textured finish for decorative or branding purposes

- Lightweight with a high strength-to-weight ratio

- Easy to clean and maintain for food-contact and sanitary uses

- Compatible with anodizing, powder coating, and other surface treatments

Typical Alloys and Tempers

Embossed aluminum circle sheets are usually manufactured from non-heat-treatable alloys with good formability:

| Alloy Series | Common Alloys | Typical Tempers | Main Characteristics |

|---|---|---|---|

| 1xxx | 1050, 1060, 1100 | O, H12, H14 | High purity, excellent ductility, good conductivity |

| 3xxx | 3003, 3004 | O, H14, H16 | Higher strength than 1xxx, better corrosion resistance |

| 5xxx | 5052, 5754 | O, H12, H14 | Medium strength, strong corrosion resistance, marine capable |

For cookware and lighting reflectors, 1050, 1060, 1100, and 3003 in temper O or H14 are often preferred. For traffic and exterior applications, 5052 or 5754 offers improved strength and durability.

Chemical Composition (Typical Ranges)

Below are typical composition ranges according to common international standards; exact values vary by alloy and specification.

1xxx Series (Example: 1050, 1060, 1100)

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Others (%) | Al (%) |

|---|---|---|---|---|---|---|---|---|

| 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | — | ≤0.05 | ≤0.03 | ≥99.50 |

| 1060 | ≤0.25 | ≤0.35 | ≤0.05 | ≤0.03 | — | ≤0.05 | ≤0.03 | ≥99.60 |

| 1100 | ≤0.95* | ≤0.95* | 0.05–0.20 | — | — | ≤0.10 | ≤0.05 | ≥99.00 |

*Combined Si + Fe for 1100.

3xxx Series (Example: 3003)

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Others (%) | Al (%) |

|---|---|---|---|---|---|---|---|---|

| 3003 | ≤0.60 | ≤0.70 | 0.05–0.20 | 1.0–1.5 | — | ≤0.10 | ≤0.15 | Balance |

5xxx Series (Example: 5052)

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Others (%) | Al (%) |

|---|---|---|---|---|---|---|---|---|---|

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | ≤0.15 | Balance |

Surface Patterns and Finishes

The embossing pattern is selected according to function and aesthetic needs.

| Pattern Type | Appearance | Typical Uses |

|---|---|---|

| Stucco | Irregular, diffuse texture | Insulation cladding, decorative panels |

| Orange Peel | Fine, dimpled surface | Cookware, food trays, non-slip bases |

| Hammer / Pebble | Irregular hammered look | Decorative covers, interior design |

| Custom Logo | Branded or special pattern | OEM cookware, promotional products |

Finish and post-treatment options:

| Treatment | Description | Benefit |

|---|---|---|

| Mill finish | As-rolled, slightly matte | Cost-effective, suitable for further processing |

| Anodized | Electrochemical oxide layer | Harder surface, color options, improved corrosion |

| Color coated | Polyester or PVDF coating | Enhanced decoration and weather resistance |

| Clear lacquer | Transparent organic coating | Stain resistance for cookware and containers |

Applications

Because of their round shape and embossed surface, these sheets are widely used across multiple sectors.

Cookware and Kitchenware

- Non-stick cookware bases

- Frying pans, woks, and saucepans

- Lids, pot bottoms, and hot plates

- Food-service trays and warming platters

The embossed texture helps distribute heat more evenly, improves grip on stovetops or racks, and hides minor scuffs from repeated washing.

Lighting and Reflectors

- Lamp shades and reflector plates

- LED housing components

- Interior decorative lighting discs

Embossed finishes can diffuse light, reducing glare while maintaining high reflection efficiency, especially in high-purity alloys.

Traffic and Industrial Signage

- Reflective sign blanks

- Marker plates and tags

- Road safety devices and barrier panels

Embossed patterns help minimize visual defects, enhance durability, and provide a distinctive look for regulatory or branding purposes.

Decorative and Architectural Elements

- Ceiling medallions and rosettes

- Wall and column cladding discs

- Interior design accents and furniture details

The textured surface adds depth and character, especially when anodized or color coated.

Technical Specifications

Typical supply ranges can be customized according to project or OEM requirements.

Dimensional Range

| Parameter | Standard Range |

|---|---|

| Diameter | 80 mm – 1,200 mm (custom up to ~1,500 mm) |

| Thickness | 0.4 mm – 6.0 mm |

| Thickness Tolerance | ±0.02 mm – ±0.10 mm (depending on gauge) |

| Diameter Tolerance | ±0.5 mm – ±1.0 mm |

| Flatness | ≤0.5% of diameter (typical) |

| Edge Type | Sheared or deburred, as specified |

Mechanical Properties (Reference Values)

Values vary with alloy and temper; typical ranges are shown below.

| Alloy / Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Notes |

|---|---|---|---|---|

| 1050-O | 60–100 | 20–30 | ≥30 | Excellent deep drawability |

| 1060-O | 60–110 | 20–30 | ≥30 | High ductility |

| 1100-H14 | 95–125 | 60–100 | ≥10 | Good strength, formability |

| 3003-O | 80–130 | 30–55 | ≥25 | Better strength vs 1xxx |

| 3003-H14 | 130–180 | 115–145 | ≥7 | Higher strength, moderate formability |

| 5052-O | 110–150 | 55–95 | ≥20 | Good marine and outdoor performance |

| 5052-H14 | 180–230 | 130–180 | ≥7 | Strong, still formable |

Physical and Performance Data

| Property | Typical Value |

|---|---|

| Density | ~2.70 g/cm³ |

| Melting Point | ~650 °C |

| Coefficient of Thermal Expansion | ~23 × 10⁻⁶ /K |

| Thermal Conductivity | 130–235 W/m·K (alloy dependent) |

| Electrical Conductivity | 35–60 % IACS (higher for 1xxx) |

| Corrosion Resistance | Good to excellent in most environments |

Processing and Forming

Embossed aluminum circle sheets are designed to run smoothly on standard metal-forming lines.

| Process | Suitability | Notes |

|---|---|---|

| Deep drawing | Very good in O and soft tempers | Common for cookers, pots, and pans |

| Spinning | Excellent, especially in 1xxx and 3xxx | Allows complex shapes and flared profiles |

| Stamping / Blanking | Suitable across all alloys | Embossing does not significantly affect cut quality |

| Bending | Good; tighter radii possible in softer tempers | Edge cracking minimized with proper alloy choice |

| Welding | Good with 1xxx, 3xxx, 5xxx (MIG/TIG) | Keep cleanliness and alloy compatibility in mind |

| Surface Finishing | Anodizing, brushing, coating | Embossed pattern remains visible under finish |

Quality Control and Standards

Manufacturers typically produce embossed aluminum circle sheet in compliance with widely recognized standards:

| Standard / Code | Scope |

|---|---|

| ASTM B209 | Aluminum and aluminum-alloy sheet and plate |

| EN 485 / EN 573 | Aluminum and aluminum alloys, sheets, chemical composition |

| ISO 6361 | Wrought aluminum sheets, strips, and plates |

| Food-contact regulations | On request, for cookware grades |

Dimensional checks, surface inspection, mechanical testing, and, where necessary, food-contact or corrosion tests are applied to each batch to ensure consistent performance.

Packaging and Supply Options

To prevent damage to the embossed surface, special attention is given to packaging and logistics.

| Option | Description |

|---|---|

| Stacked on pallets | Interleaved with paper or film |

| Shrink-wrapped | Moisture-resistant outer protection |

| Wooden cases | Export-ready, enhanced edge protection |

| Protective film | PE film on one or both sides optional |

Custom labeling, barcoding, and palletization are available for OEM and large-volume customers.

Choosing the Right Embossed Aluminum Circle Sheet

When selecting material for your application, consider:

- Alloy and temper based on forming depth and strength required

- Diameter and thickness suited to final product geometry

- Embossing pattern for slip resistance, light diffusion, or aesthetic effect

- Surface finish (mill, anodized, color coated) according to environment and design

- Certification and regulatory requirements for food-contact or outdoor use

By matching these factors with your production process and end-use conditions, embossed aluminum circle sheets provide a durable, light, and visually appealing solution for both functional and decorative applications.

https://www.al-alloy.com/a/embossed-aluminum-circle-sheet.html