Aluminum Plate A1050, A1060, A1070, A1100

12/31 2025

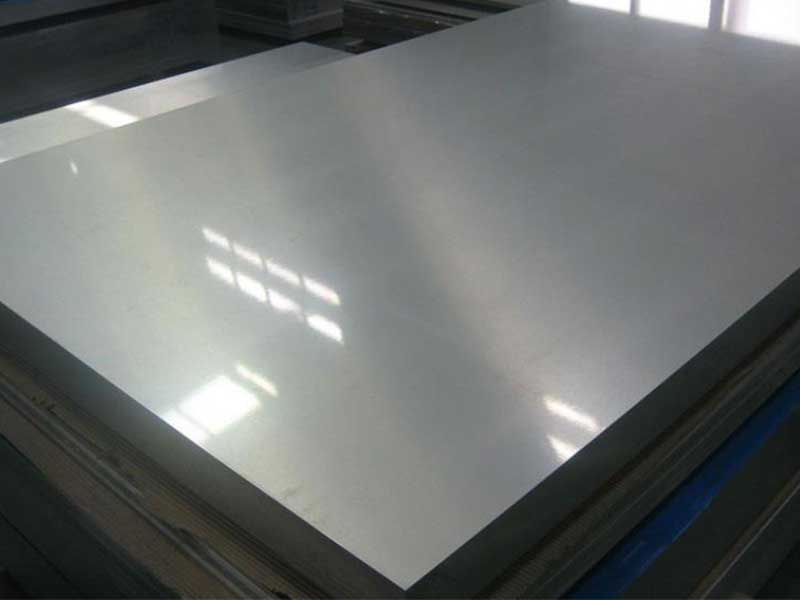

Aluminum plates A1050, A1060, A1070, and A1100 are classic “commercially pure” aluminum grades. They offer excellent corrosion resistance, high electrical and thermal conductivity, and outstanding formability. These properties make them ideal for applications where strength requirements are moderate, but cleanliness, conductivity, and workability are critical.

| Alloy | Aluminum Content (typical) | Series | Temper Range (common) | Characteristics |

|---|

| A1050 | ≥ 99.50% | 1xxx | O, H12, H14, H18 | Very high conductivity, excellent formability |

| A1060 | ≥ 99.60% | 1xxx | O, H14, H18 | Higher purity than 1050, better corrosion resistance |

| A1070 | ≥ 99.70% | 1xxx | O, H14, H16, H18 | Ultra-high purity, superior electrical performance |

| A1100 | ≥ 99.00% | 1xxx | O, H14, H16, H18, H24 | Slightly alloyed for better strength and machinability |

All four alloys belong to the non-heat-treatable 1xxx series, strengthened primarily by cold working (strain hardening).

Features

Core Performance Characteristics

| Feature | A1050 / A1060 / A1070 | A1100 |

|---|

| Purity | Very high (≥ 99.5 / 99.6 / 99.7% Al) | High (≥ 99.0% Al) |

| Corrosion Resistance | Excellent in most atmospheric & many chemical environments | Excellent; slightly influenced by minor Cu |

| Electrical Conductivity | Very high (up to ~60% IACS for A1070) | High (~55–57% IACS, depending on temper) |

| Thermal Conductivity | High for all grades | High |

| Formability (Cold) | Outstanding, suitable for deep drawing & spinning | Very good, slightly stronger than pure grades |

| Weldability | Excellent (TIG, MIG, resistance) | Excellent; often used in general fabrication |

| Machinability | Fair (gummy in soft tempers) | Better than ultra-pure thanks to minor alloying |

| Surface Finish Quality | Very good, suitable for anodizing & polishing | Very good, suitable for decorative finishes |

Chemical Composition

Typical chemical composition limits (wt. %) according to common standards (values are indicative; actual limits may vary slightly by standard and producer).

| Alloy | Si (max) | Fe (max) | Cu (max) | Mn (max) | Mg (max) | Zn (max) | Ti (max) | Others (Each) | Others (Total) | Al (min) |

|---|

| A1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 0.03 | 0.15 | 99.50 |

| A1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | 0.03 | 0.10 | 99.60 |

| A1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | 0.04 | 0.03 | 0.03 | 0.10 | 99.70 |

| A1100 | 0.95 (Si+Fe) | – | 0.05–0.20 | 0.05 | 0.05 | 0.10 | 0.05 | 0.05 | 0.15 | 99.00 |

The progression from A1050 → A1060 → A1070 represents increasing aluminum purity and correspondingly improved conductivity and corrosion resistance.

A1100 is slightly alloyed, chiefly with copper, for increased strength.

Mechanical & Technical Specifications

Typical mechanical properties at room temperature (reference values; vary by standard, thickness, and producer).

Mechanical Properties by Temper

| Alloy – Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Typical Use Focus |

|---|

| A1050-O | 60–100 | 20–35 | 25–40 | Deep drawing, forming, spinning |

| A1050-H14 | 95–125 | 70–90 | 10–20 | General panels, covers, enclosures |

| A1050-H18 | 125–145 | 110–130 | 4–10 | Where higher stiffness is required |

| A1060-O | 60–95 | 20–35 | 25–40 | Conduits, flexible components |

| A1060-H18 | 120–140 | 105–125 | 4–10 | Electrical bus bars, stiff plates |

| A1070-O | 55–90 | 15–30 | 30–40 | Ultra-conductive formed parts |

| A1070-H18 | 115–135 | 100–120 | 4–10 | High-conductivity flat stock |

| A1100-O | 60–110 | 20–35 | 25–40 | General forming, tanks, vessels |

| A1100-H14 | 110–145 | 95–125 | 10–20 | Building sheets, sign boards |

| A1100-H18 | 140–165 | 125–150 | 4–10 | Nameplates, stiff facings |

Physical Properties

| Property | Typical Value Range | Notes |

|---|

| Density | ~2.70 g/cm³ | All alloys similar |

| Melting Range | ~645–660 °C | Slight variations with minor alloying |

| Electrical Conductivity | ~55–62 % IACS | Higher for A1070, slightly lower for A1100 |

| Thermal Conductivity | ~220–235 W/m·K | High thermal efficiency for heat transfer |

| Coefficient of Thermal Expansion | ~23–24 ×10⁻⁶ /K | Typical for 1xxx series |

| Modulus of Elasticity | ~69 GPa | Common to most wrought aluminum alloys |

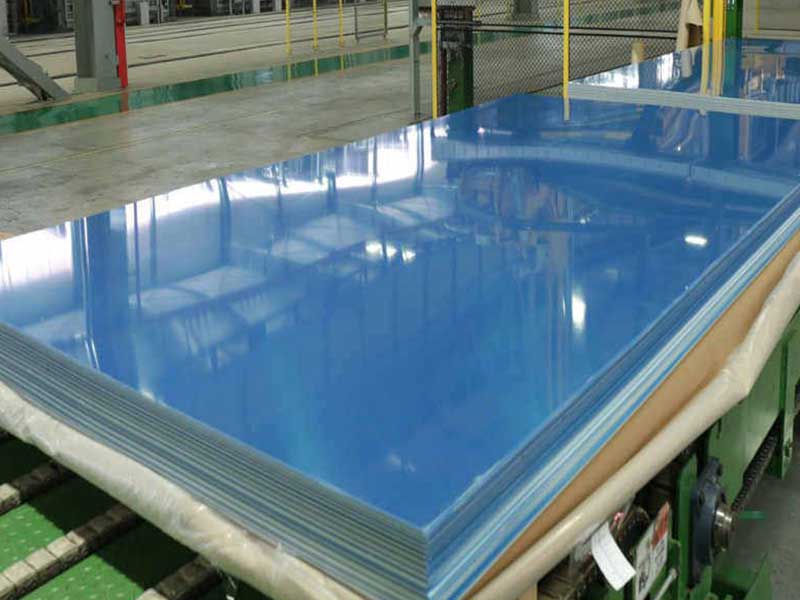

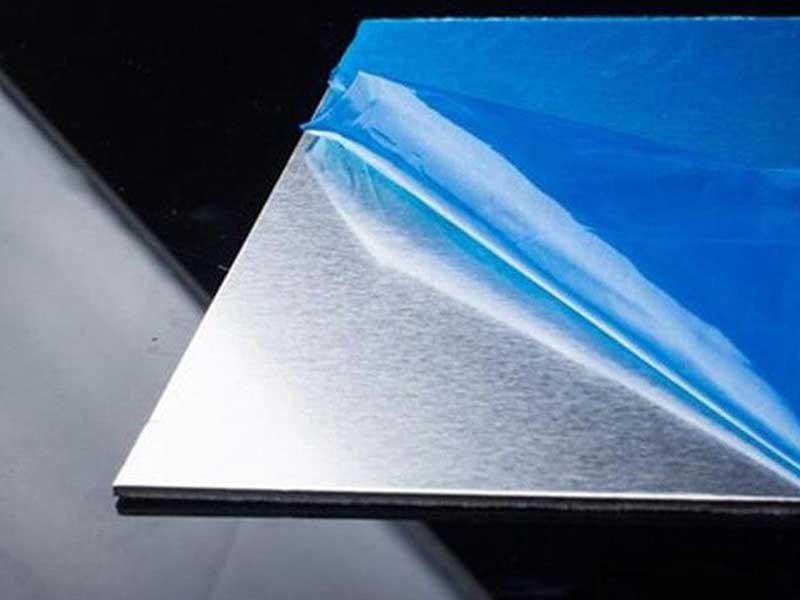

Available Dimensions & Surface Options

Typical supply range (can be customized depending on mill capability):

| Parameter | Typical Range |

|---|

| Thickness | 0.20 mm – 200 mm (sheet to heavy plate) |

| Width | Up to 2,000 mm or more |

| Length | Up to 8,000 mm or as per customer request |

| Surface Finish | Mill finish, brushed, embossed, anodized, PVC-coated |

| Edge Condition | Mill edge, slit edge |

Differences Between A1050, A1060, A1070, and A1100

| Requirement / Priority | Recommended Alloy | Reason |

|---|

| Maximum electrical conductivity | A1070 | Highest purity, minimal alloying elements |

| Balanced purity & cost | A1060 or A1050 | Good conductivity with cost-effective performance |

| Slightly higher strength | A1100 (H14, H18) | Minor Cu alloying for improved strength |

| Deep drawing, spinning | A1050-O / A1060-O | Excellent ductility and formability |

| Decorative anodizing | A1050 / A1060 / A1100 | Good surface finish, stable anodic film |

| Chemical equipment | A1050 / A1060 / A1070 | High purity, low contamination risk |

Main Applications

Electrical & Electronic

| Application Type | Preferred Grade(s) | Reason |

|---|

| Bus bars, current-carrying bars | A1060, A1070 | High conductivity, easy fabrication |

| Transformer windings (strip, plate) | A1070, A1060 | Ultra-high purity for low loss |

| Cable shielding and covers | A1050, A1060 | Good conductivity and formability |

| Electronic housings & chassis | A1100, A1050 | Good strength-to-weight, excellent workability |

Heat Transfer & HVAC

| Application | Preferred Grade(s) | Feature Highlights |

|---|

| Heat exchanger cladding | A1050, A1060 | High thermal conductivity, good bonding |

| Air conditioner fins | A1050, A1100 | Thin gauge formability, good thermal performance |

| Radiator & cooler plates | A1060, A1100 | Balance of strength and conductivity |

Building, Architecture & Signage

| Use Case | Preferred Grade(s) | Benefits |

|---|

| Roofing & façade panels | A1100-H14 | Adequate strength, corrosion resistance, formability |

| Indoor decorative panels | A1050, A1100 | Good surface finish, easy bending and cutting |

| Sign boards & nameplates | A1100-H18 | High rigidity, clean surface for printing |

| Curtain wall back plates | A1050, A1100 | Lightweight, good weldability |

Industrial, Chemical & Food Contact

| Application | Preferred Grade(s) | Remarks |

|---|

| Storage tanks (non-high-pressure) | A1050-O, A1100-O | Formable, corrosion resistant |

| Chemical equipment liners | A1060, A1070 | High purity, low contamination risk |

| Food processing trays & plates | A1050, A1060 | Non-toxic, easy to clean, good thermal response |

| Pharmaceutical packaging base sheet | A1070 | Ultra-clean, high purity surface |

General Fabrication & Consumer Products

| Product Type | Preferred Grade(s) | Highlights |

|---|

| Kitchen utensils | A1050, A1100 | Good stamping, clean surface, food-safe |

| Lighting reflectors | A1050, A1060 | High reflectivity after polishing/anodizing |

| Household appliances covers | A1100 | Better strength, attractive finish |

| Hardware, brackets, shields | A1050, A1100 | Easy cutting, punching, and bending |

Processing & Fabrication Notes

| Process | Suitability | Notes |

|---|

| Cold forming | Excellent | Suitable for deep drawing, spinning, bending |

| Welding | Excellent (TIG/MIG) | Use suitable filler alloys; minimal hot cracking risk |

| Machining | Fair to moderate | Use sharp tools, high rake angles to reduce gumming |

| Anodizing | Very good | Produces clear, hard coating; alloy selection affects color tone |

| Brazing & Soldering | Good (depending on filler) | Low melting point; temperature control is important |

Why Choose A1050, A1060, A1070, or A1100 Aluminum Plate?

| Advantage | How It Helps You |

|---|

| High purity & conductivity | Improves efficiency in electrical and thermal equipment |

| Excellent formability | Reduces forming force, tool wear, and scrap rate |

| Lightweight | Lowers structure weight and transportation costs |

| Corrosion resistance | Extends service life, especially in outdoor applications |

| Clean, smooth surface | Ideal for anodizing, painting, printing, and decoration |

| Stable and recyclable | Fully recyclable with minimal property loss |

These four alloys cover a broad range of needs: from ultra-pure conductive plate (A1070) to cost-effective, slightly stronger commercial sheet (A1100). By choosing the right alloy and temper, you can tailor the balance of strength, purity, formability, and surface quality to match your exact application.

1050

1060

1070

1100

https://www.al-alloy.com/a/aluminum-plate-a1050-a1060-a1070-a1100.html