Aluminum slugs for collapsible tube

In the dynamic landscape of packaging solutions, the humble aluminum slug exhibits astonishing versatility and impeccable utility, especially in the realm of collapsible tubes. Often overshadowed by flashier packaging materials, aluminum slugs offer a host of benefits that appeal to manufacturers and consumers alike.

What are Aluminum Slugs?

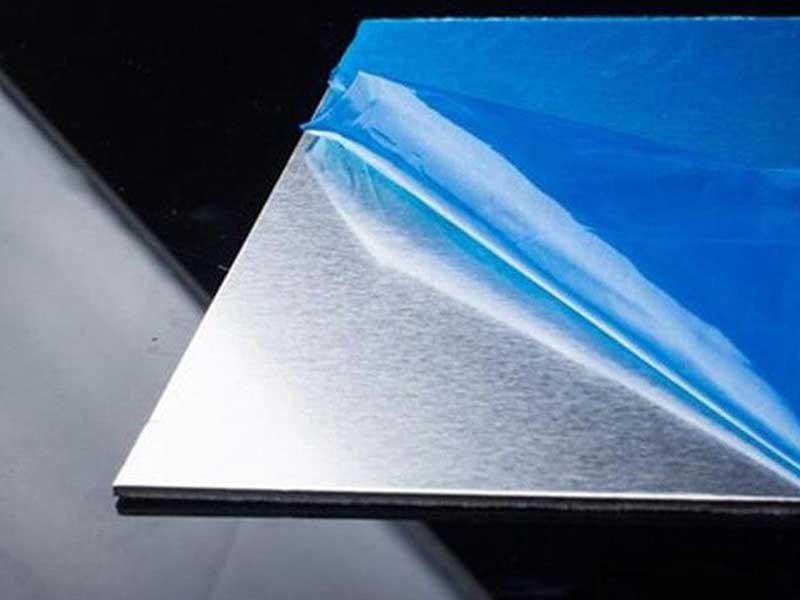

Aluminum slugs are disc-shaped blanks produced from heated aluminum coils, typically in a rolling mill or die-cutting process. More than mere metal disks, these slugs evolve into effective and efficient resources for packaging applications. Most notably, they serve as the very foundation for collapsible aluminum tubes, which are commonly used for everything from cosmetics to pharmaceuticals.

The Sustainable Edge

In a world increasingly gravitating towards sustainability, aluminum points directly at the shining beacon of possibility. Aluminum is 100% recyclable, making it an eco-friendly option that appeals to manufacturers seeking to align with environmental values. When crafting collapsible tubes, using aluminum slugs enables recyclability while ensuring that the end product remains lightweight yet sturdy. Not to mention, the ability of aluminum to resist corrosion guarantees product security and longer shelf-life, which is crucial for items like ointments and adhesives.

Features That Spell Usage

Superior Formability: Aluminum slugs can be easily formed into various shapes without jeopardizing the integrity of the material. This plays a crucial role in simplifying the production of collapsible tubes, allowing for uniform thickness and smooth surfaces, which enhances printing capabilities for branding.

Lightweight Nature: In packaging, weight is a big deal. Consumers are now more cognizant of waste and the overall ecological footprint, making lightweight materials not just a modern-day trend but a keen expectation. Aluminum slugs contribute to this weight-saving game, bolstering transport efficiency and lowering shipping costs.

Excellent Barrier Properties: An often-overlooked aspect! Aluminum's natural metal barrier assists in blocking moisture, light, and oxygen. Such properties ensure that products inside collapsible tubes maintain their efficacy over time, which is especially vital in the pharmaceutical sector.

Manufacturing Processes and Parameters

The journey of aluminum slugs involves specific parameters and standards that are pivotal for consistent quality in collapsible tube production:

Material Specifications: 1100-H14 and 1050-H24 are two commonly used aluminum alloys for manufacturing slugs due to their excellent formability and bright visual appeal.

- 1100-H14: Commercial aluminum with good corrosion resistance.

- 1050-H24: Known for superb ductility and workability, often preferred for tubes that require precise shapes.

Thickness and Size Considerations: The thickness of the slugs typically falls between 0.5 mm to 1.5 mm, depending on the design and purpose of the collapsible tube, while diameter specifications can range based on specific product requirements – usually between 25 mm to 80 mm.

- Guideline: A consistent thickness also aids in a smooth manufacturing process, ensuring seals remain intact once tubes are filled and packaged.

Quality Control Standards: Compliance with standards like ASTM B649 (Standard Specification for Aluminum Direct Investment Casting Alloys) ensures that slugs used fulfill stringent quality requirements. Other metrics fluctuate based on application, but tensile strength and elongation are critical indicators always examined during quality inspections.

Tempering Choices

Aluminum undergoes various tempering processes to attain the desired hardness, ductility, and strength characteristics. The two primary tempering conditions of interest in manufacturing collapsible tubes from aluminum slugs are:

- H14 (Strain-Hardened): Imparts improved yield and tensile strength while maintaining manageable formability;

- H24 (Strain-Hardened and Partially Annealed): Balances ductility with tensile strength; often the choice for tubes needing efficient crimping or closing processes.

Final Thoughts: Why Choose Aluminum Slugs for Collapsible Tubes?

From ecological agendas to engineering excellence, the choice of aluminum slugs for creating collapsible tubes emerges as a bona fide winner in contemporary packaging solutions. Its combination of sustainability, formability, and protective properties positions it directly in the sweet spot of modern consumer demands.

In essence, the next time you twist open a collapsible tube, take a moment to appreciate the masterpiece inside—the aluminum slug. It isn’t just a structure; it’s a carefully designed solution representing innovation, reliability, and a pledge toward a sustainable future for products that matter. The simplicity and effectiveness of this metal marvel are reminders that ingenuity often lies beneath the surface of everyday items, shaping our packaging experience in ways we often neglect—but no longer need to!

https://www.al-alloy.com/a/aluminum-slugs-for-collapsible-tube.html