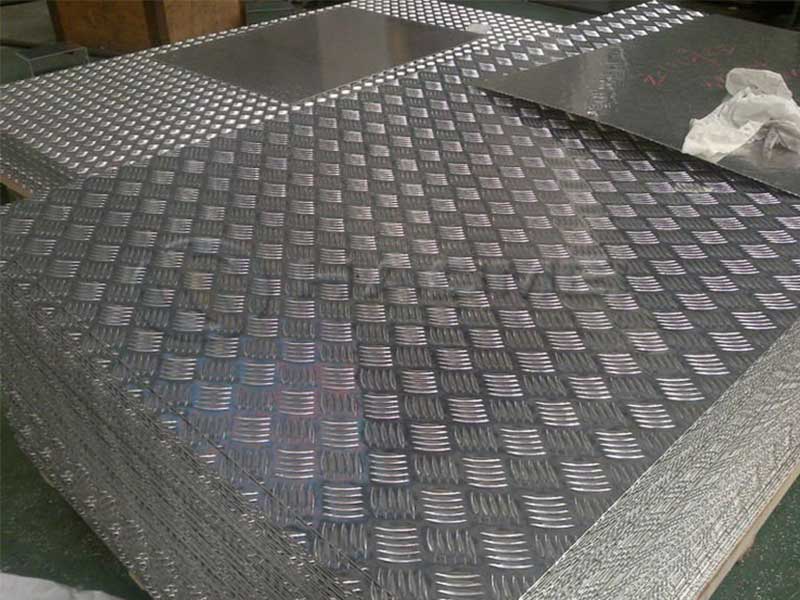

Chequer aluminum plate flooring

Chequer aluminum plate flooring, often referred to as aluminum tread plate or diamond plate, is an exceptional material widely used in various industries due to its distinct combination of durability, lightweight nature, and anti-slip properties. Its uniquely textured surface proves vital for ensuring safety and aesthetic appeal across numerous environmental conditions and applications.

Chequer aluminum plate flooring primarily serves a safety function, offering slip resistance in both indoor and outdoor environments. The “chequered” or “tread” pattern embossed on the surface increases the friction coefficient, effectively reducing slip and fall hazards. Besides safety, this flooring option is highly valued for its strength-to-weight ratio, corrosion resistance, and easy maintenance, making it suitable for industrial, commercial, and decorative purposes.

- Slip Resistance: The raised pattern enhances traction, significantly improving footing on wet, oily, or greasy surfaces.

- Corrosion and Weather Resistance: Aluminum’s natural oxide layer shields it against rust, ideal for harsh chemical environments and humid conditions.

- Lightweight but Strong: Reduces structural load and makes installation relatively simple without compromising strength.

- Impact and Pressure Resistance: Maintains integrity under heavy foot traffic or vehicle movement.

- Aesthetic Appeal: The polished or brushed finish supports modern architectural designs and vehicle outfitting.

Common Applications of Chequer Aluminum Plate Flooring

Because of the robust and functional properties, chequer aluminum plates have found widespread use across diverse applications:

- Industrial and Factory Flooring: High anti-slip assistance in manufacturing plants and workshops.

- Transport Vehicles: Floors and steps on buses, trucks, ambulances, trailers, and trains.

- Loading Ramps and Stairs: Provides safe walking surfaces under heavy infrastructural strain.

- Commercial Kitchens: Combines hygiene standards with proven slip-proof safety.

- Architectural Projects: Modern decor indoors or in outdoor public spaces, like bridges and walkways.

- Marine Applications: Deck flooring exposed to moisture and salt environments.

- Elevated Platforms and Catwalks: Safety flooring where critical access and maintenance are required.

Technical Specifications and Standards

Chequer aluminum plate flooring adheres to international and regional quality standards to ensure consistent performance and manufacturing accuracy. Below is a overview of technical parameters:

| Parameter | Details |

|---|---|

| Standard | ASTM B209, EN 485-2, JIS H4000 |

| Product Type | Aluminum tread/chequer plate flooring |

| Thickness Range | 1.5 mm to 10 mm |

| Width | Up to 1500 mm (customizable based on client need) |

| Length | Available in customized sheets or coils |

| Weight | Typically 2.7 g/cm³ (aluminum density) |

| Alloy Series | 1XXX, 3XXX, 5XXX (commonly used alloys) |

| Temper | H14, H22, H24 (strain-hardened tempers, varying strengths) |

| Surface Finish | Polished, brushed, or mill-finish with injected tread pattern |

Alloy and Tempering Conditions

The performance properties highly depend on the aluminum alloy used and its tempering. Using the correct combination affects mechanical properties such as hardness, ductility, and yield strength.

| Alloy Series | Main Element | Temper Codes | Remarks |

|---|---|---|---|

| 1050 | 99.5% Al | H14, H24 | Excellent corrosion resistance, good electrical conductance |

| 3105 | Al + Si + Mg | H14 | Good corrosion resistance, improved strength |

| 5052 | Al + Mg | H32, H34 | High strength, great corrosion resistance, marine integrity |

Temper notes:

- H14: Half hard, strain-hardened to moderate strength.

- H24: Strain-hardened then partially annealed for increased firmness with flexibilities.

- H32/H34: Strain-hardened then stabilized, offering good combination of strength and toughness.

Chemical Composition of Common Aluminum Alloys in Chequer Plate Flooring

alloy composition helps predict applications and machining characteristics.

| Alloy | Al (min%) | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1050 | 99.5 | 0.25 | 0.40 | 0.05 | 0.03 | 0.03 | — | 0.03 | 0.03 |

| 3105 | 97.3-99.0 | 0.6-0.9 | 0.6 | 0.1 | 0.2-0.6 | 0.05-0.20 | — | 0.2 | 0.05 |

| 5052 | 97.25 | 0.40 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 | 0.03 |

Mechanical Properties

| Property | 1050-H14 | 3105-H14 | 5052-H32 |

|---|---|---|---|

| Tensile Strength (MPa) | 90-110 | 140-165 | 228-284 |

| Yield Strength (MPa) | 35-60 | 90-110 | 193-241 |

| Elongation (%) | 20-35 | 10-18 | 10-12 |

| Hardness (HV) | ~40 | ~55 | ~75 |

Implementation Standards and Quality Control

Chequer aluminum plates conform strictly to ASTM B209 / EN 485 for dimensions and mechanical performance. Additionally, inspection for thickness tolerance, surface quality (pattern uniformity), and oxidative treatment is standard practice, ensuring consistency.

Quality certifications often include:

- ISO 9001 - Quality Management Systems

- RoHS Compliant - Hazardous Substance-Free

- REACH Compliant - Chemical Safety Regulation

https://www.al-alloy.com/a/chequer-aluminum-plate-flooring.html