Coated 8011 Ptp Aluminum Foil

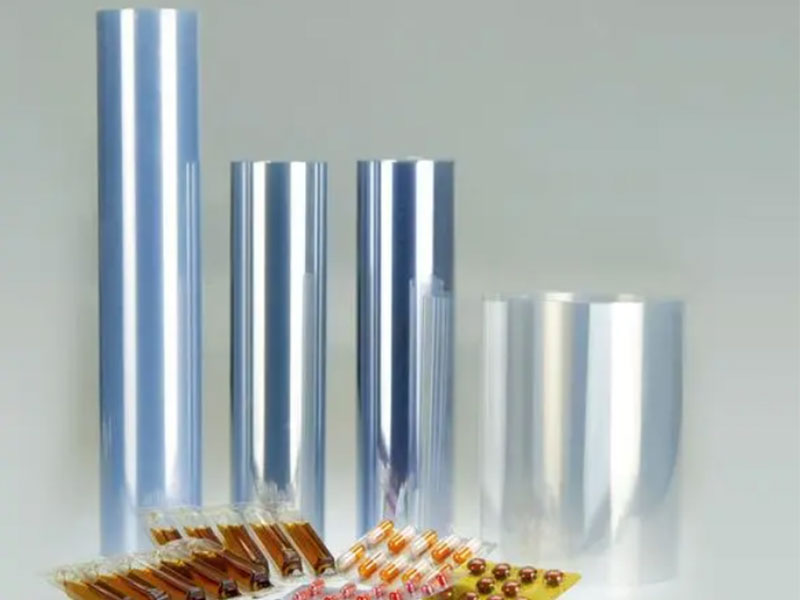

Aluminum foil is a versatile material widely used in various industries, and one of its specialized variants is 8011 PTP (Pharmaceutical Blister) Aluminum Foil. With its unique features that align with pharmaceutical safety and durability, coated 8011 PTP aluminum foil plays a critical role in the modern pharmaceutical packaging industry.

What is 8011 PTP Aluminum Foil?

8011 PTP aluminum foil is a type of aluminum packaging film that meets stringent chemical and physical properties, essential for products that require precise control over contamination, humidity, and light exposure. The “PTP” in its name stands for “Press Through Pack”, indicating its functionality in creating blister packs.

Features

- Barrier Protection: Offers superior protection against air, moisture, and light, ensuring the medicines remain effective throughout their shelf life.

- Heat Sealing Properties: Designed for efficient heat sealing packaging processes, making it easy to adhere to a range of forming materials.

- Biomedical Stability: It maintains the integrity of the packaging in environments with varying atmospheric conditions.

Application Areas

Coated 8011 PTP aluminum foil's psi make it ideal for numerous applications like:

- Pharmaceutical Packaging: Most commonly used for blister packs for tablets and capsules. Ensures dosage integrity.

- Food Packaging: Projects a protective barrier for moisture-sensitive food items.

- Cosmetics: Often used for packaging creams and ointments sensitive to oxidation and contamination.

Technical Specifications

The materials used in coated 8011 PTP aluminum foil undergo strict regulatory standards to ensure safety and efficacy in its application. Here are the technical compositions and parameters of the 8011 PTP aluminum foil:

Technical Data Table

Chemical Composition

| Material | Composition (%) |

|---|---|

| Aluminum | 98.0 - 99.3 |

| Iron | ≤ 0.05 |

| Silicon | ≤ 0.25 |

| Copper | ≤ 0.05 |

| Manganese | ≤ 0.15 |

| Zinc | ≤ 0.10 |

Technical Specifications

| Property | Value |

|---|---|

| Alloy Grade | 8011 |

| Structure | Single-layer |

| Thickness | 0.02mm - 0.4mm |

| Width | Customized |

| Surface Coating | Yes |

| Tensile Strength | ≥ 150 MPa |

| Elongation | ≥ 2% |

Implementation Standards

- ASTM B449: Covers the specifications regarding aluminum and aluminum-alloy sheets & plates.

- ISO 15378: Specifies requirements for a quality management system specifically regarding materials for packaging in medicinal products, emphasizing its property of preventing contamination.

Alloy Tempering Conditions

The major tempering conditions for 8011 PTP aluminum foil include:

| Condition | Parameter |

|---|---|

| Ambient Temp | -10°C to 40°C |

| Annealing Temp | 300°C - 550°C |

| Cooling Rate | Moderate cooling (1°C/min) |

Chemical Properties

Coated 8011 aluminum foil is reactive under certain chemical conditions and hence possesses some essential chemical properties that guarantee its structural safety in pharmaceutical usage:

| Property | Value |

|---|---|

| Corrosion Resistance | High |

| Reaction with Acids | Not reactive |

| Reaction with Bases | Not reactive |

| pH Stability | 4.5 to 9 |

Advantages of Using Coated 8011 PTP Aluminum Foil

- Efficiency in Production: Adapts well to high-line speeds of pharmaceutical manufacturing.

- Cost-effective: Due to its considerable resource-efficiency in production, reducing operational costs.

- Eco-friendly: Recycling practices for aluminum assist in reducing landfill waste.

https://www.al-alloy.com/a/coated-8011-ptp-aluminum-foil.html