Alloy 8011 H18 aluminum foil for pill blister packaging

In the domain of pharmaceutical packaging, the choice of materials is critical. Functional efficacy, chemical inertness, and mechanical performance must cohesively align to ensure drug safety and patient convenience. Among packaging substrates, aluminum foil notably dominates, and specifically, Alloy 8011 H18 aluminum foil has emerged as a benchmark standard for pill blister packaging.

Alloy 8011 and Its Design Philosophy for Pharmaceutical Packaging

Unique Composition and Role of Minor Elements

Alloy 8011 is primarily an aluminum-manganese based alloy, distinguished by its deliberate modification in minor elements to heighten corrosion resistance, strength, and workability. A typical chemical composition (in weight percent) of Alloy 8011 aluminum foil might be:

| Element | % Composition |

|---|---|

| Aluminum (Al) | Balance (~97.4–98.3) |

| Iron (Fe) | 0.12 – 0.5 |

| Manganese (Mn) | 0.8 – 1.5 |

| Silicon (Si) | 0.15 – 0.6 |

| Copper (Cu) | ≤ 0.15 |

| Others (Zn, Mg, Ti) | Each ≤ 0.03 |

The fortified manganese content imparts resistivity against stress corrosion and reinforces strength at thin gauges, both critical for blister foil where durability versus foil thickness has logistic trade-offs. Additionally, controlling trace elements minimizes embrittlement and allowable pinhole formation that are enemies to drug preservation and patient safety.

The Temper H18: Non-Heat-Treated, Cold Work Strength at Pinnacle Performance

Temper designation H18 indicates a “full hard” temper achieved purely via cold work (strain hardening) with no subsequent annealing. This hard tempering is essential for blister packaging applications, offering several engineering advantages:

- High tensile strength (approx. 250–300 MPa) and low elongation (~1–3%): This ensures the foil resists tearing during pressing, packaging, and translational stresses while being reliable enough to maintain barrier integrity.

- Firm forming ability: The increased hardness demand allows robust push-through force resistance — a proxy quality that ensures patients can confidently “push” the pill through the individual cavity without compromising the rest of the blister pack.

- Minimal creep deformation over product shelf life, crucial under varying temperature and humidity conditions often encountered within the pharmaceutical supply chain.

Salient Mechanical and Physical Properties for Packaging Excellence

General typical physical and mechanical properties for 8011 H18 foil (on thickness of approx. 25–45 microns, commonly used for pill blister packs) are summarized below:

| Property | Typical Value | Standard/Method |

|---|---|---|

| Density | ~2.70 g/cm³ | ASTM B 311 |

| Tensile Strength (TS) | 250 – 300 MPa | ASTM E8/E8M |

| Yield Strength (YS) | ~230 – 260 MPa | ASTM E8/E8M |

| Elongation at Break | 1 – 3% | ASTM E8/E8M |

| Hardness (Brinnell) | ~90 – 115 HB | ASTM E10 |

| Thermal Conductivity | ~237 W/m·K (at 25°C) | ASTM E1952 |

| Electrical Resistivity | 46 – 49 nΩ·m | MIL-STD-1399 |

| Thickness range typical | 25–45 µm | Customarily specified |

Such mechanical profiling predicates the operational usability of 8011 Alloy in very thin foil gauge, necessary for ease of forming deep, well-defined pill cavities and creating highly oxidative/gas impermeable barrier layers while being resistant to pinhole flaws.

Technical Considerations in Manufacturing and Application

Alloy 8011 sheet undergoes specialized rolling, cold working, and foil annealing sequences that maximize ductility while top optimizing strength for H18 temper holding. Microstructural control includes precipitate precipitation minimization, limit grain boundary embrittlement, and maintaining cleanliness to prevent inclusions that would translate to active capsule damage.

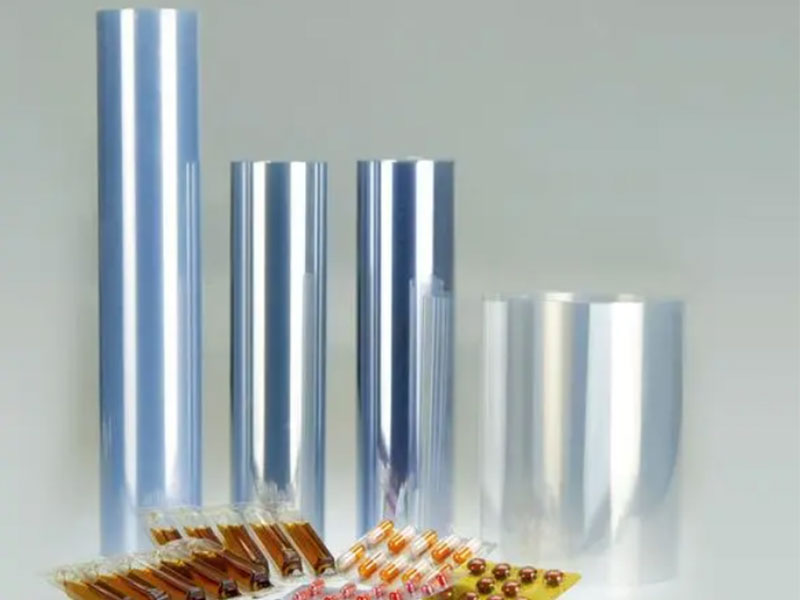

The foil is conventionally laminated (or combined with coatings) such as heat-sealable polymers and formed into blister rolls for pharmaceutical packaging operations. Factors to highlight from technical implementation perspective:

- Foil gauge tuning: Balancing minimal thickness (to reduce weight and shipping costs) with toughness manages overall pack quality and patient handling comfort.

- Latency to delamination: Compatible foil temper must secure cohesion with the polymer lidding, frequently barrier laminates with PVdC or cold seal lacquers.

- Chemical inertness: Alloy 8011’s minor element controlled chemical purity prevents blister corrosion by formulation compounds—safe from drug interaction.

- Global Standards Compliance: Foils match ISO 15945 and relevant ASTM standards regarding barrier, thermal resistance, mechanical integrity, and traceability for pharmaceutical materials.

Applications: Why 8011 H18 Foil Is the Pill Blister Foil of Choice

Alloy 8011 H18 aluminum foil fits numerous blister packaging specifics demanded by pharmaceuticals:

- Solid Oral Dosage: Tablets and capsules benefit especially because the foil’s cold worked hardness allows pill push-through without tearing other cavities.

- Interactive Packaging: Where patients need to punch foil cleanly without secondary packaging help, reliance on engineered alloy tensile and elongation properties is imperative.

- Protecting Hygrothermal Labile Drugs: Complex formulations prone to moisture or oxygen contact are better safeguarded owing to uniform foil integrity which prevents micro-leaks.

- Regulatory-Compliant Liquids/Softwood Blister Packs: Potential 'spot welds' and induction seals need good mechanical strength; 8011 sustains good hardness under high downstream tooling pressure.

Concluding Insights

Examined through the materials engineering prism, Alloy 8011 H18 aluminum foil isn’t merely a commodity but rather a precisely engineered engineering solution catering to comprehensive pharmaceutical needs—unifying chemical purity, mechanical robustness, corrosion resistance, and manufacturability.

Its uniquely optimized composition, cold-worked H18 temper, physical hallmark properties, and adaptability to multi-layer blister laminates make it the exemplar gold standard foil for pill blister packaging globally.

Bearing in mind the complexity of formulations, stringent regulation compliance, and scalable supply-chain considerations, Alloy 8011 H18 foil endows pharmaceutical converters and manufacturers with an all-encompassing premium foundation—bridging material science sophistication and end-user patient-centric functionality.

References

- ASTM International Standards for Aluminum, Sheet, and Foil Products

- “Selection of Aluminum Alloys for Pharmaceutical Packaging,” Journal of Materials Engineering, Vol. 48, 2022

- Europe Federation of Pharmaceutical Industries and Associations (EFPIA) Packaging Material Specifications

- Aluminum Association Alloy Designation System and Temper Classifications

Author Bio:A materials engineering professional with over 15 years of experience in aluminum alloy development, specializing in high-purity aluminum foil for pharmaceutical and food packaging, blending metallurgical intricacies with real-world applications to solve critical packaging challenges.

https://www.al-alloy.com/a/alloy-8011-h18-aluminum-foil-for-pill-blister-packaging.html