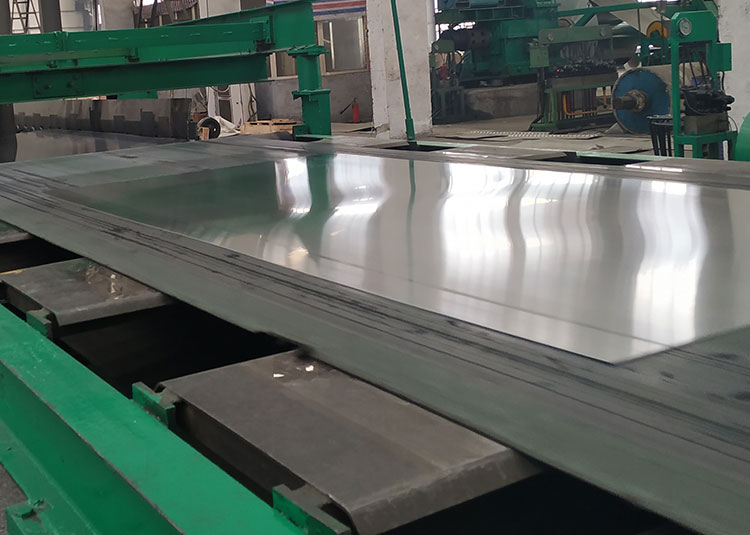

Aluminum sheets

Aluminum sheets are one of the most widely used semi-finished products in modern manufacturing. They combine low weight, good strength, excellent corrosion resistance, and outstanding formability, making them suitable for everything from household appliances to aerospace panels.

Aluminum sheets are flat-rolled products with thickness typically from 0.20 mm to 6.00 mm (above this range, products are often classified as plate). They are supplied in coils or cut-to-size sheets, with a variety of surface finishes and tempers.

Common alloy families used for sheets include:

- 1xxx series – Commercially pure aluminum (e.g., 1050, 1100)

- 3xxx series – Aluminum-manganese (e.g., 3003)

- 5xxx series – Aluminum-magnesium (e.g., 5052, 5083)

- 6xxx series – Aluminum-magnesium-silicon (e.g., 6061, 6082)

Each alloy family balances strength, corrosion resistance, and formability differently, supporting applications from decorative panels to structural components.

2. Features and Benefits

2.1 Core Features

Low Density

Approx. 2.70 g/cm³, about one-third the weight of steel, enabling lighter structures and reduced energy consumption in transportation.High Corrosion Resistance

Forms a stable oxide film that protects against atmospheric, marine, and many industrial environments, especially in 1xxx, 3xxx, and 5xxx series.Good Strength-to-Weight Ratio

Strength can be tailored via alloying and temper selection; 5xxx and 6xxx series provide medium to high strength at low weight.Excellent Formability and Workability

Well-suited for bending, deep drawing, roll forming, and stamping, especially in annealed tempers (e.g., O, H14).Superior Thermal and Electrical Conductivity

Ideal for heat exchangers, HVAC equipment, and electrical busbars (particularly 1xxx series).Recyclability

100% recyclable with minimal loss of properties, reducing environmental footprint and total lifecycle cost.

2.2 Benefits for Customers

- Reduced Structural Weight → Lower fuel consumption, improved handling, and easier installation.

- Long Service Life → Excellent corrosion resistance minimizes maintenance and repainting.

- Processing Flexibility → Compatible with cutting, punching, folding, welding, and coating.

- Consistent Quality → Controlled chemical composition and mechanical properties for stable forming and joining behavior.

3. Typical Chemical Composition (Representative Alloys)

The table below shows indicative chemical composition ranges for three commonly used sheet alloys (values in wt.%). Actual mill specifications may vary slightly.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others (each) | Al (approx.) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | – | ≤0.05 | ≤0.03 | ≤0.03 | ≥99.50 |

| 3003 | ≤0.60 | ≤0.70 | 0.05–0.20 | 1.0–1.5 | – | – | ≤0.10 | – | ≤0.05 | Balance |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | ≤0.03 | ≤0.03 | Balance |

| 6061 | 0.40–0.80 | ≤0.70 | 0.15–0.40 | 0.15–0.40 | 0.80–1.2 | 0.04–0.35 | ≤0.25 | ≤0.15 | ≤0.05 | Balance |

- 1050: High purity, very good conductivity and formability, low strength.

- 3003: Non-heat-treatable, improved strength via Mn, good corrosion resistance.

- 5052: Non-heat-treatable, Mg alloy, excellent corrosion resistance, medium strength.

- 6061: Heat-treatable, good strength and machinability, widely used in structural parts.

4. Mechanical Properties and Performance

4.1 Typical Mechanical Properties

Representative values for 1.0–3.0 mm thick sheets (room temperature):

| Alloy & Temper | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation A50 (%) | Notable Characteristics |

|---|---|---|---|---|

| 1050-H14 | 95–125 | 75–105 | 5–12 | Very high formability, low strength |

| 3003-H14 | 130–180 | 115–160 | 5–10 | Good balance of formability and strength |

| 5052-H32 | 210–260 | 130–180 | 7–14 | Good strength, excellent corrosion resistance |

| 5083-H111 | 275–345 | 125–215 | 10–18 | Marine grade, high corrosion resistance in seawater |

| 6061-T6 | 260–320 | 240–280 | 8–12 | High strength, good machinability and weldability |

Note: Property values are indicative and vary with thickness and exact processing conditions.

4.2 Physical and Thermal Properties

| Property | Typical Value (Al Alloys) | Notes |

|---|---|---|

| Density | ~2.70 g/cm³ | About 1/3 of steel |

| Melting Range | 580–660 °C | Depends on alloying content |

| Thermal Conductivity | 120–220 W/m·K | 1xxx > 5xxx > 6xxx in general |

| Electrical Conductivity | 30–60 % IACS | 1050, 1100 are highest |

| Coefficient of Thermal Expansion | ~23 × 10⁻⁶ /K | Important for joint and assembly design |

| Modulus of Elasticity (E) | ~69–72 GPa | Lower than steel; relevant for stiffness |

5. Technical Specifications

5.1 Available Dimensions

Typical commercial ranges (custom sizes available on request):

| Parameter | Standard Range | Remarks |

|---|---|---|

| Thickness | 0.20 – 6.00 mm | Below 0.20 mm usually foil |

| Width | 600 – 2000 mm | Wider sheets on request |

| Length (cut sheets) | 1000 – 6000 mm | Longer lengths per project |

| Coil Inner Diameter | 405 / 505 / 610 mm | Depends on mill equipment |

| Coil Outer Diameter | Up to 2000 mm | Subject to handling limitations |

| Coil Weight | 1 – 10 tons | Tailored to customer’s process |

5.2 Standard Surface Conditions

| Surface Finish | Description | Typical Applications |

|---|---|---|

| Mill finish | As-rolled surface | General fabrication, further coating |

| Brushed | Unidirectional, decorative texture | Interior panels, appliances, signage |

| Embossed (stucco, diamond, etc.) | Patterned surface for aesthetics and slip resistance | Cladding, flooring, toolboxes |

| Anodized | Electrochemically oxidized, colored or clear | Architectural, decorative, corrosion-critical |

| Painted / Pre-coated | Organic coating (PE, PVDF, etc.) | Building facades, roofing, appliances |

5.3 Dimensional Tolerances (Indicative)

Conforming typically to EN, ASTM, or GB standards:

| Thickness (mm) | Tolerance (mm) |

|---|---|

| 0.20–<0.50 | ±0.03 to ±0.04 |

| 0.50–<1.00 | ±0.04 to ±0.05 |

| 1.00–<3.00 | ±0.05 to ±0.07 |

| 3.00–6.00 | ±0.07 to ±0.12 |

Actual tolerances depend on standard and product grade.

6. Processing and Fabrication

Aluminum sheets are compatible with a wide set of fabrication processes:

| Process | Suitability | Notes |

|---|---|---|

| Shearing / Blanking | Excellent | Clean edges with proper clearance |

| Bending / Folding | Very good (esp. 1xxx, 3xxx, 5xxx) | Bend radius depends on alloy & temper |

| Deep Drawing | Excellent for 1xxx, 3xxx series | Used in cookware, automotive parts |

| Welding (MIG/TIG) | Good for 5xxx, 6xxx alloys | Filler selection critical |

| Resistance Welding | Good for thin sheets | Common in automotive body-in-white |

| Machining | Good, best in 6xxx series | Use sharp tools and appropriate lubricants |

| Coating / Painting | Very good; pre-treatment recommended | Compatible with anodizing and organic coats |

7. Major Applications

7.1 Construction and Architecture

- Exterior wall cladding and curtain wall panels

- Roofing and gutters

- Ceiling systems and internal wall panels

- Window sills, flashing, and decorative elements

advantages: low maintenance, weather resistance, wide color range via anodizing/painting, and ease of on-site fabrication.

7.2 Transportation

- Body panels for trucks, trailers, buses, and rail cars

- Floor and side panels for refrigerated vehicles

- Marine applications (decks, hull plating with marine alloys)

Benefits: weight reduction → higher payload and lower fuel consumption; good corrosion resistance in road-salt and marine environments.

7.3 Industrial and Mechanical

- Machine guards, covers, and panels

- Heat exchangers, HVAC ducting, evaporator plates

- Storage tanks (especially 5xxx series for non-pressurized tanks)

Benefits: good heat transfer, easy maintenance, and high resistance to many industrial atmospheres.

7.4 Electrical and Consumer Products

- Enclosures for electrical and electronic equipment

- Appliance panels (refrigerators, ovens, washing machines)

- Lighting reflectors (using high-reflectivity aluminum sheets)

Benefits: excellent thermal management, decorative appearance, and high reflectivity for lighting.

8. Selection Guidance

When selecting aluminum sheets, consider:

| Requirement | Recommended Alloy Family | Notes |

|---|---|---|

| Maximum formability | 1xxx, 3xxx | For deep drawing, spinning, complex bends |

| High corrosion resistance (marine) | 5xxx | For marine, coastal, and chemical use |

| Higher structural strength | 5xxx, 6xxx | 5083, 5754, 6061, 6082, etc. |

| High thermal / electrical conductivity | 1xxx | For busbars, heat sinks, reflectors |

| Decorative / architectural finish | 3xxx, 5xxx | Compatible with anodizing and coating |

Align alloy, temper, thickness, and surface finish with the end-use environment and forming requirements.

Aluminum sheets offer a combination of low weight, versatile strength levels, corrosion resistance, and excellent processability. With a broad spectrum of alloys, tempers, thicknesses, and finishes, they provide reliable solutions for:

- Building and architectural facades

- Transportation and marine structures

- Industrial equipment and heat transfer systems

- Appliances, electrical enclosures, and decorative components

By the chemical composition, mechanical performance, and processing behavior of different aluminum sheet alloys, customers can choose the most cost-effective and technically sound solution for their specific application.