Orange Peel Pattern Aluminum Sheet Coil Plate

In the realm of aluminum fabrication, surface texture is no longer a mere aesthetic appendage but a critical determinant of function. One interesting and often underappreciated format that links texture with multifaceted utility is the Orange Peel Pattern Aluminum Sheet Coil Plate. More than just a quaint design trademark, this patterned aluminum coil represents a synthesis of material science and design innovation tailored for modern industrial and architectural applications.

the Orange Peel Pattern: Beyond Texture

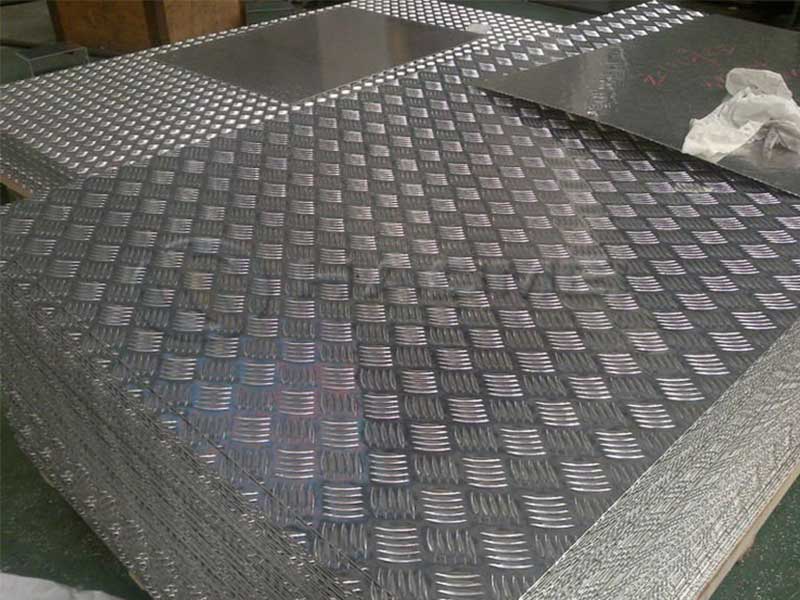

At first glance, the term “orange peel” might call to mind just a cosmetic resemblance: a pebbled, undulating surface similar to the pith of an orange peel. Technically, this is an embossed surface pattern imparted onto aluminum coil plates through calibrated rolling or pressing techniques during manufacturing. Unlike smooth aluminum surfaces that reflect light uniformly and tend to emphasize minor imperfections, orange peel-textured sheets scatter incident light in multiple directions, producing a visually diffuse finish.

From an engineering standpoint, the pattern is achieved by altering the die rolls or calibrated embossing rollers, which create a proprietary topographical fingerprint across the sheet’s surface. Typically, the raised cone- or dimple-shaped undulations range in micro-micron to sub-millimeter scale—minuscule elevations sufficient to disrupt reflective glare but subtle enough to maintain the metal’s structural integrity. Such precise texturizing requires advanced cold-rolling technology combined with stringent material surface conditioning, ensuring that the mechanical properties of aluminum alloys remain consistent post-processing.

Features Emanating from the Orange Peel Texture

Anti-Glare PropertyThe fragmented reflection diffuses direct sunlight and artificial illumination, significantly diminishing glare. This feature is invaluable in setups requiring visual comfort and suppressing eye strain from intense reflections—such as transportation terminals, control rooms, and certain architectural dazzlers.

Enhancement of Paint AdhesionThe pattern increases the effective surface roughness which aids in the mechanical bonding of finishes and primers. Paint or powder-coated finishing adheres more robustly on orange peel sheets compared with slick smooth sheets—resulting in enhanced corrosion resistance, longevity, and maintenance-friendly surfaces.

Improved Material Rigidity and Tactile GripWhile thin gauge aluminum sheets typically are prone to minor warping and bending, the embossed texture marginally increases stiffness by introducing micro reinforcement structures. The three-dimensional texture also provides improved tactile grip wherever panel handling or manual erection matters, for example in architectural facade panels or equipment housings.

Distinctive Visual and Haptic AppealApart from utility, the stylish textured effect energy imbues products with quality appearance elevating aluminum from industrial raw-product into advertising, display, and premium-grade architecture themes. This discreetly incorporates tactile legacy preserving channels hampering visual fatigue and unavoidable dust/dirt marking.

Applications Driven by Functional Texturing

Architectural Cladding and Roofing: Orange peel patterned aluminum coils offer a balanced combination of aesthetic charm and protective outdoor resistance. Facades benefit both from reduced surface glare for viewers’ eyes and stronger resistance to abrasion during maintenance and environmental wear.

Automotive Componentry: Traditionally focusing on abrasion facets, the orange peel pattern finds roles particularly on inner panel trims, dashboards, and embellishment trims where durability melded with a matte finish avoids fingerprint smudging and glare-induced distractions.

Appliance Manufacturing: Household and commercial appliances incorporate orange peel aluminum plates to mask fingerprints, improve paint bonding quality, and elevate overall product resilience under continuous handling and wipe-clean routines.

Furniture Industry: Profiled aluminum sheets provide a modern industrial finish desirable in veneer or hardware. The functional texture means easier cleaning and wear resistance, factors much prized in healthcare, laboratory, or commercial interior stadium recoveries.

Technical Considerations When Selecting Orange Peel Aluminum Sheets

the aluminum base properties complemented by the orange peel pattern is critical:

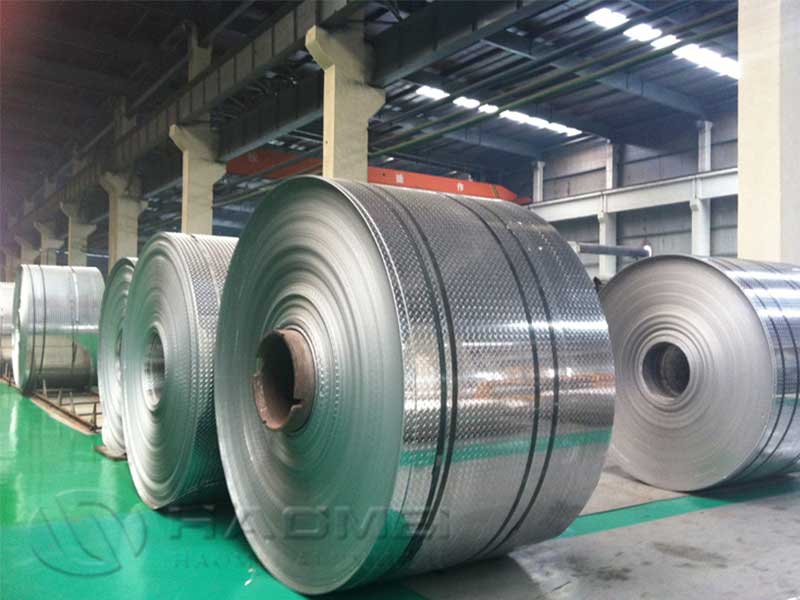

Alloy Grade: Predominantly, 3003H14 or 5052H32 alloys find widespread thermomechanical adaptation owing to their well-balanced properties—corrosion resistance coupled with excellent formability fitting embossing machinations.

Coil Thickness and Temper: Common coil thickness ranges from 0.2mm up to 3mm according to application load demands. Typical tempers such as H14 and H18 ensure work-hardening levels amenable to induced patterns while sustaining tensile strength targets.

Surface Treatment Preprocessing: Pre-embossing surface cleaning, degreasing, and optional conversion coating preparation are pivotal steps impacting coating adhesion and textural uniformity post embossment.

Color and Coating: Options include anodizing or PVDF-based painting which further leverage surface roughness and direct UV resistance supported by subtle microstructures.

https://www.al-alloy.com/a/orange-peel-pattern-aluminum-sheet-coil-plate.html