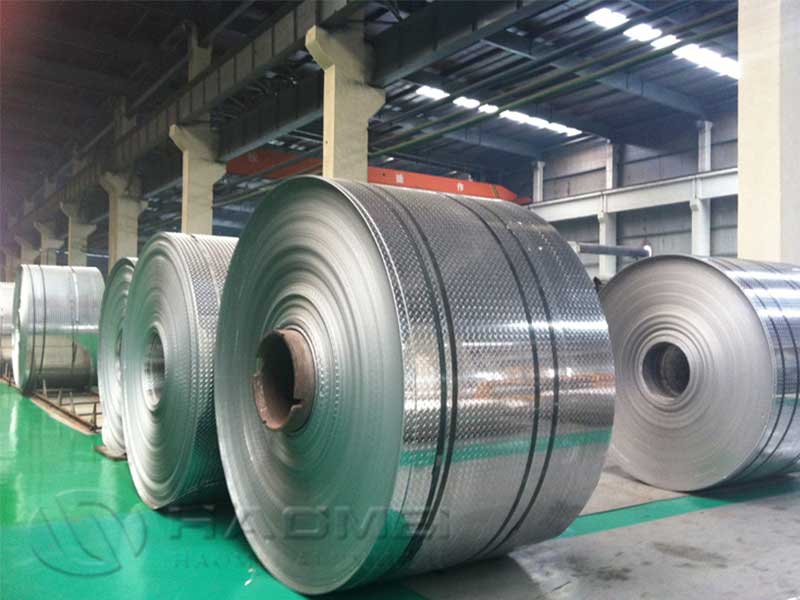

Aluminium chequered plate

Aluminium Chequered Plate: A "Surface Engineering" Material That Solves More Than Slip

Aluminium chequered plate (also called aluminium tread plate or aluminium diamond plate) is often purchased for one obvious reason: traction. Yet its real value is broader. From a surface-engineering viewpoint, chequered plate is a pre-built performance layer that combines grip, visual guidance, and impact tolerance with the low mass and corrosion resistance of aluminium. The raised pattern is not decoration; it's a functional geometry that changes how people walk, how loads slide, how water drains, and how a panel resists local denting.

When customers evaluate aluminium chequered plate only by thickness and price, they miss what it is actually "doing" in service: controlling friction, wear, and usability in harsh environments while remaining easy to fabricate and maintain.

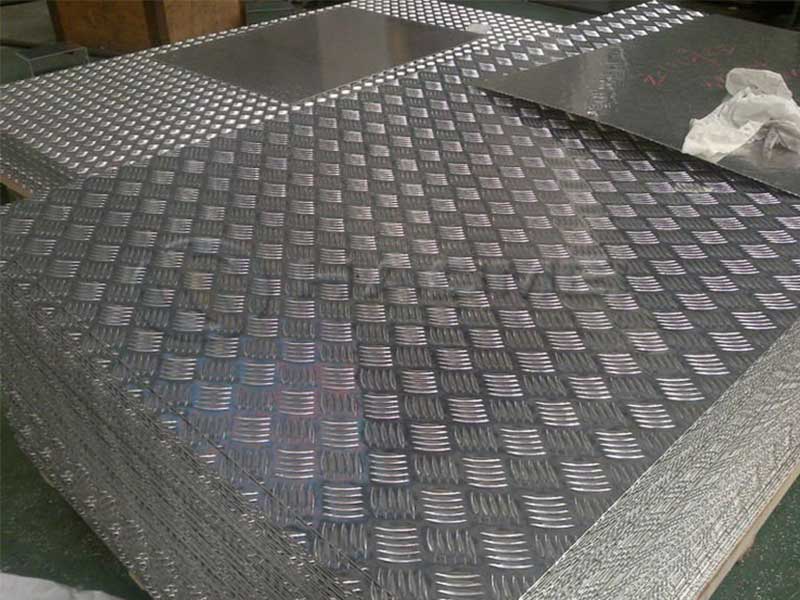

What the pattern really does: friction, drainage, and stiffness in one move

The defining feature is the raised chequer pattern, typically five-bar, diamond, or similar variations. This geometry increases the coefficient of friction under foot and under cargo, especially when surfaces are wet or oily. It also disrupts continuous water film formation, helping drainage and reducing hydroplaning-like effects for shoes and wheels.

The raised ribs also behave like micro-stiffeners. Compared with a flat sheet of the same nominal thickness, chequered plate can show improved resistance to localized denting and scuffing because the peaks absorb first contact. In practical terms, that can reduce visible wear in high-traffic areas like truck steps, maintenance platforms, and trailer floors.

Another underrated function is visual signaling. The texture reads as "walkway," "step," or "access panel" at a glance. In industrial sites and commercial vehicles, that instant recognition supports safer movement without additional labels.

Why aluminium for chequered plate: corrosion behavior and weight economics

Aluminium's advantage is not only that it doesn't rust. Many common alloys form a stable oxide film that protects the surface in atmospheric exposure. In marine and de-icing salt conditions, selecting a marine-grade alloy can substantially improve service life. The weight reduction versus steel is often the quiet cost saver: lighter floors, steps, and enclosures can increase payload capacity and reduce fuel consumption, while also making installation faster and safer.

Chequered plate is also easy to work with using standard sheet fabrication methods. It can be cut, drilled, bent, and fastened with typical shop equipment. Welding is possible for many alloys, although the best alloy choice depends on whether the final structure is welded, bolted, or bonded.

Common alloys and tempers: choosing "how it behaves" under load and in fabrication

Alloy selection determines corrosion resistance, strength, formability, and weldability. Temper describes how the material achieved its properties, which matters when you bend it, weld it, or expose it to fatigue.

Typical selections include:

- 1xxx series (such as 1050, 1100): excellent corrosion resistance and formability, lower strength. Suitable for light-duty coverings, decorative panels, and environments where easy forming matters more than structural strength.

- 3xxx series (such as 3003): a classic choice for general-purpose tread plate. It offers better strength than 1xxx while keeping good corrosion resistance and workability. Often supplied in H22/H24 tempers for a balance of strength and formability.

- 5xxx series (such as 5052, 5083, 5754): higher strength and strong corrosion resistance, especially in marine and chloride-rich settings. Common in vehicle bodies, ship fittings, offshore platforms, and washdown areas. Tempers like H114 or H32 are widely used for plate products.

Temper guidance from a practical, "in-service" viewpoint:

- H22/H24: strain-hardened and partially annealed. Often chosen when you need forming (bending around framing) without sacrificing too much strength.

- H32: stabilized strain-hardened. Good for parts that see moderate forming and want consistent mechanical behavior.

- H114: commonly used for tread plate products; it indicates a plate/strip condition with specified properties suitable for forming and service use.

Parameters customers actually use on-site

Chequered plate is ordered by a few core parameters that determine fit, performance, and installation speed:

- Thickness: commonly around 1.5–6.0 mm for flooring, steps, and panels, with heavier gauges for ramps and truck bodies. Some specifications reference "base thickness" excluding pattern height; confirm whether thickness includes the raised bars.

- Pattern type: five-bar is popular for walking surfaces; diamond patterns are common for cargo and vehicle applications.

- Sheet size: common widths include 1000, 1220, 1250, 1500 mm; common lengths include 2000, 2440, 3000 mm, often customizable.

- Surface finish: mill finish is typical; bright or anodized finishes may be used for aesthetics or easier cleaning.

- Flatness and tolerances: important for flooring and door panels where fit-up matters.

Standards and implementation: speaking the language of projects and procurement

Different regions and industries use different standards. Aluminium chequered plate is typically produced and inspected under recognized specifications such as:

- EN 485 (Europe) for aluminium and aluminium alloy sheet/strip: mechanical properties and tolerances

- EN 573 for chemical composition

- ASTM B209 (commonly referenced internationally) for aluminium and aluminium-alloy sheet and plate

- EN 1386 may be referenced for tread plate in some procurement contexts depending on product category and market practice

In real projects, the implementation standard is also the installer's standard: ensuring correct fastener selection, isolation from dissimilar metals to limit galvanic corrosion, and using anti-slip orientation consistently across walk paths.

Applications: where the chequer pattern pays for itself

Aluminium chequered plate is best understood as a "wear layer" that also carries load.

Transportation and logistics commonly use it for truck floors, trailer ramps, step plates, toolboxes, and cargo area linings. The pattern helps prevent pallet and equipment sliding, and the aluminium base reduces vehicle weight.

Industrial access and maintenance areas use it for platforms, catwalks, stairs, machine room walkways, and removable service covers. The texture improves footing, and the plate is easier to lift than steel when panels must be removed frequently.

Marine and coastal infrastructure often adopts 5xxx alloys for gangways, dock walkways, and boat steps because the combination of corrosion resistance and grip performs well in wet, salty air.

Architecture and commercial interiors use chequered plate as a durable, contemporary finish for wall protection, kick plates, ramps, and back-of-house floors where cleaning and impact resistance are priorities.

Chemical composition table (typical ranges)

Actual limits depend on the exact standard and mill certification. The table below summarizes widely used typical composition limits for common alloys used in aluminium chequered plate procurement.

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) | Al (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1100 | ≤0.95 (Si+Fe) | - | 0.05–0.20 | ≤0.05 | - | - | ≤0.10 | - | ≥99.0 |

| 3003 | ≤0.60 | ≤0.70 | 0.05–0.20 | 1.0–1.5 | - | - | ≤0.10 | - | Balance |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | - | Balance |

| 5754 | ≤0.40 | ≤0.40 | ≤0.10 | ≤0.50 | 2.6–3.6 | ≤0.30 | ≤0.20 | ≤0.15 | Balance |

| 5083 | ≤0.40 | ≤0.40 | ≤0.10 | 0.4–1.0 | 4.0–4.9 | 0.05–0.25 | ≤0.25 | ≤0.15 | Balance |

The distinctive takeaway: it's a "human-interface" plate

Aluminium chequered plate succeeds because it sits at the boundary between people, equipment, and environment. The raised pattern manages slip and motion. The alloy manages corrosion and strength. The temper manages how the sheet behaves when fabricated and how reliably it performs in service.