Aluminum tread plate 1100 1060 3003 5052 H24 H26

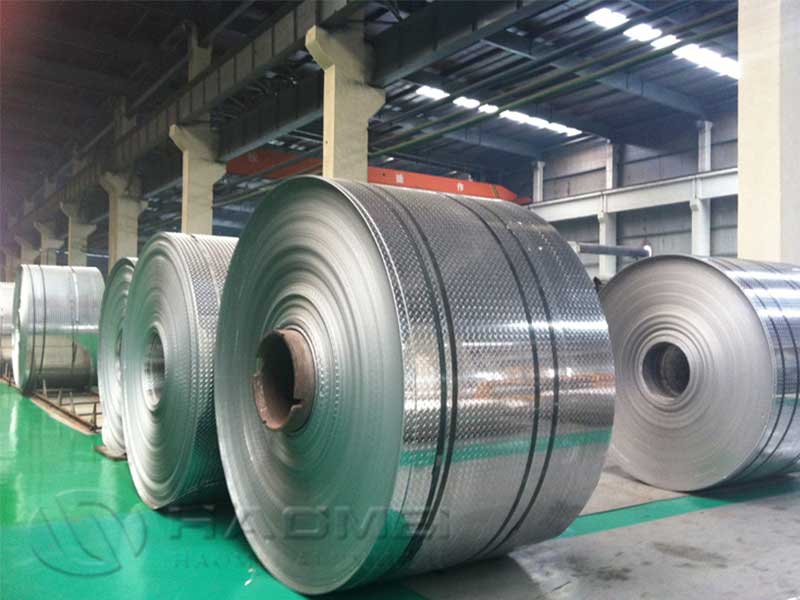

Aluminum tread plate, also known as aluminum checker plate or diamond plate, is an essential material widely used across various industries due to its durability, lightweight properties, and distinctive textured surface that offers slip resistance. Among the most common aluminum alloys employed in tread plates are 1100, 1060, 3003, and 5052. When combined with tempering conditions like H24 and H26, these alloys provide a balance of strength, corrosion resistance, and formability suitable for numerous applications.

Aluminum Tread Plate Alloys and Tempering

Aluminum tread plates feature raised patterns that increase grip, making them ideal for floorings, ramps, vehicle bodies, and various industrial surfaces that require enhanced safety.

Common Aluminum Alloy Families Used:

| Alloy | Primary Characteristic | Typical Uses |

|---|---|---|

| 1100 | Commercially pure aluminum (99%+), excellent corrosion resistance, high ductility | Decorative and architectural applications, chemical equipment |

| 1060 | Very high purity, excellent corrosion resistance and electrical conductivity | Electrical and food processing industries |

| 3003 | Alloyed with manganese, moderate strength, good corrosion resistance | Roofing, siding, and edging materials |

| 5052 | Alloyed with magnesium, high strength, excellent corrosion resistance, particularly in marine environments | Marine, automotive, and industrial applications |

Tempering States: H24 and H26

The temper codes reflect different mechanical and chemical conditioning after production:

| Temper | Description | Properties |

|---|---|---|

| H24 | Strain-Hardened and partially annealed | Medium strength, excellent formability, good weldability |

| H26 | Strain-Hardened and quarter annealed | Higher hardness and strength with moderate ductility |

Tempering directly affects properties like tensile strength and flexibility essential for choosing the right tread plate for your application.

Technical Specifications

The following table highlights essential mechanical properties relevant to aluminum tread plate alloys in temper H24 and H26 conditions.

| Property | 1100-H24 | 1100-H26 | 1060-H24 | 1060-H26 | 3003-H24 | 3003-H26 | 5052-H24 | 5052-H26 |

|---|---|---|---|---|---|---|---|---|

| Tensile Strength (MPa) | 105 - 120 | 130 - 145 | 105 - 115 | 125 - 135 | 145 - 160 | 160 - 175 | 240 - 275 | 260 - 290 |

| Yield Strength (MPa) | 55 - 65 | 70 - 78 | 50 - 60 | 65 - 75 | 105 - 115 | 115 - 125 | 170 - 200 | 190 - 215 |

| Elongation (%) | 10 - 18 | 6 - 12 | 12 - 20 | 7 - 14 | 10 - 15 | 4 - 10 | 7 - 12 | 4 - 9 |

| Hardness (Brinell) | 25 - 30 | 35 - 40 | 25 - 32 | 38 - 45 | 35 - 45 | 43 - 50 | 65 - 75 | 70 - 80 |

Chemical Composition (%) for Aluminum Tread Plate Alloys

Clear of chemical compositions ensures accurate selections concerning corrosion resistance, strength, and other performance indicators.

| Element | 1100 | 1060 | 3003 | 5052 |

|---|---|---|---|---|

| Aluminum (Al) | 99.0 min | 99.6 min | 96.8 min | 97.25 min |

| Copper (Cu) | 0.05 max | 0.05 max | 0.10 max | 0.10 max |

| Manganese (Mn) | 0.05 max | 0.05 max | 1.0 - 1.5 | 0.10 max |

| Magnesium (Mg) | 0.05 max | 0.03 max | 0.05 max | 2.2 - 2.8 |

| Silicon (Si) | 0.95 max | 0.20 max | 0.6 max | 0.25 max |

| Iron (Fe) | 0.95 max | 0.35 max | 0.7 max | 0.40 max |

| Zinc (Zn) | 0.10 max | 0.10 max | 0.10 max | 0.10 max |

| Titanium (Ti) | 0.03 max | 0.03 max | 0.10 max | 0.03 max |

| Others (Each) | - | - | 0.05 max | 0.05 max |

| Others (Total) | 0.05 max | 0.05 max | 0.15 max | 0.15 max |

Industry Standards & Implementation

Operators and fabricators typically refer to common standards that certify the size, thickness, pattern height, and alloy properties. The widely recognized standards include:

| Standard Code | Details |

|---|---|

| ASTM B785 | Specification for Aluminum Sheet and Plate with Marked Surface Patterns |

| AMS 4059B | Aluminum Alloy Product Specification |

| JIS 5051 / JIS 1231 | Japanese Industrial Standards for aluminum sheet products |

| EN AW – 1050, 3003, etc. | European Norm alloys for structural and chemical requirements |

Compliance with these codes guarantees the aluminum tread plate's metallurgical consistency, mechanical reliability, and finish quality necessary for demanding installations.

Common Functions and Features of Aluminum Tread Plates

- Anti-slip Surface: Raised patterns improve grip and minimize accidents, essential for walkways, staircases, vehicle floors.

- Corrosion Resistance: Superior corrosion resistance, especially in alloys like 5052, makes it excellent for marine and chemical environments.

- Lightweight Strength: Despite its reduced weight compared to steel, aluminum offers substantial structural durability and impact resistance.

- Ease of Fabrication: Easily cut, welded, rolled, and formed - broad tooling compatibility means versatile fixing and profiling.

- Aesthetic Appeal: Polished or brushed finishes meet decorative as well as protective requirements.

Typical Applications for Aluminum Tread Plate Alloys

| Application | Suitability by Alloy | Temper Preference |

|---|---|---|

| Vehicle & truck flooring | 3003, 5052 for toughness and anti-fatigue warp resistance | H24 (flexible), H26 (stronger) |

| Marine flooring and platforms | 5052 - exceptional corrosion resistance in saltwater | H24 for formability, H26 for operator durability |

| Industrial stair treads and ramps | 1060, 1100 for corrosion resistance in low-impact pedestrian areas | H24 |

| Architectural structures | 1100 due to excellent finishing and mild strength | H24 |

| Food processing & chemical units | 1100, 1060 resistant to chemical reactions | H24 (allows easier forming) |

| Outdoor equipment and facades | 3003 offers balancing corrosion resistance-purpose strength | H26 |

https://www.al-alloy.com/a/aluminum-tread-plate-1100-1060-3003-5052-h24-h26.html