Embossed aluminum sheeting

Embossed aluminum sheeting is a textured aluminum sheet engineered with a raised pattern that improves grip, hides surface wear, and adds visual character while preserving aluminum's light weight and corrosion resistance. It is widely chosen for transportation interiors, architectural cladding, insulation jacketing, cold-room panels, appliances, and packaging-related equipment-anywhere a durable, easy-to-clean surface with better scratch masking is valuable.

Unlike plain sheet, embossed sheet "works smarter" in daily service: the pattern disrupts reflections, reduces the appearance of dents and handling marks, and can improve stiffness-to-weight in certain directions. The result is a material that feels more robust in the hand and performs better in busy, high-touch environments.

What Makes Embossed Aluminum Different

Embossing is a rolling process that imprints a pattern into the sheet surface. The pattern may be applied on one side with the opposite side showing a corresponding "male/female" effect, or managed to meet a specific visual/functional preference.

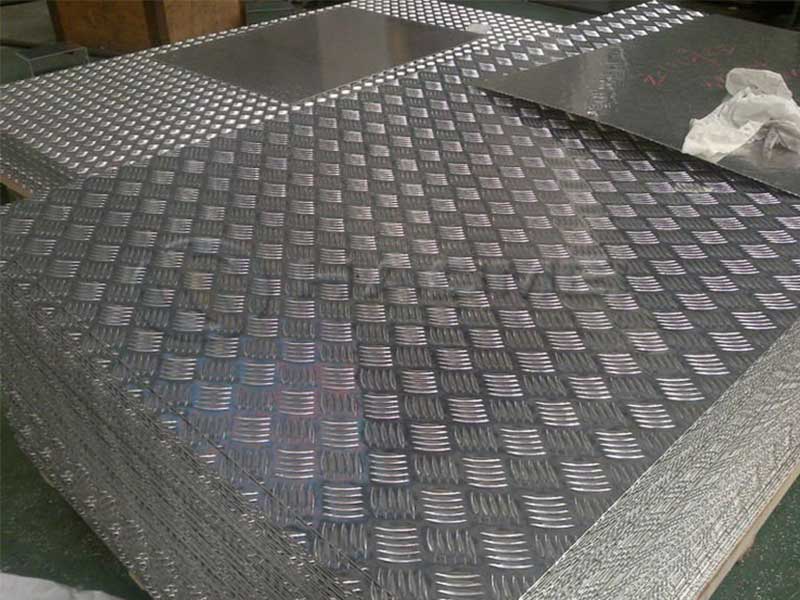

Common pattern families include:

- Stucco embossed: irregular, dimpled texture; excellent for insulation jacketing and appliance panels because it hides scratches well

- Diamond (tread) patterns: high-friction texture used for floors, steps, ramps, and vehicle walkways

- Five-bar tread: popular in transportation flooring due to stable traction and strong appearance

- Custom decorative emboss: architectural panels, signage backers, branded surfaces

Features Customers Notice Immediately

- Scratch and dent masking: the raised texture breaks up light reflections and makes handling wear less visible

- Improved grip: safer footing and better hand traction compared with smooth sheet

- Easy to clean: patterns like stucco shed fingerprints and minor smudges better than bright smooth finishes

- Better visual uniformity in large panels: texture reduces "oil canning" visibility and specular glare

- Lightweight corrosion resistance: aluminum's natural oxide layer plus optional coatings support long outdoor service

- Formability and fabrication options: can be cut, bent, riveted, and fastened with standard sheet-metal practices, while pattern choice influences bend appearance

Typical Alloy Options and Why They're Used

Embossed sheet can be produced from multiple aluminum alloy families. Selection is usually driven by corrosion environment, strength needs, forming requirements, and finishing route.

| Alloy Series | Common Alloys | Typical Strength Level | Advantages | Common Use Cases |

|---|---|---|---|---|

| 1xxx | 1050, 1060, 1100 | Low | Excellent corrosion resistance, high reflectivity, good forming | Insulation jacketing, decorative panels, appliance liners |

| 3xxx | 3003, 3004, 3105 | Medium | Very good corrosion resistance, good formability, better strength than 1xxx | Stucco sheet for HVAC, roofing accessories, cladding, cabinets |

| 5xxx | 5052, 5754 | Medium–High | Stronger, excellent marine/industrial corrosion resistance | Transport interiors, coastal architectural panels, equipment covers |

Chemical Composition (Typical Reference Ranges)

Actual chemistry varies by standard (ASTM/EN/JIS) and supplier practice. The table below offers typical ranges used in commercial production for common embossed-sheet alloys.

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Ti (%) | Al (%) |

|---|---|---|---|---|---|---|---|---|

| 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.03 | Balance |

| 1060 | ≤0.25 | ≤0.35 | ≤0.05 | ≤0.03 | ≤0.03 | ≤0.05 | ≤0.03 | Balance |

| 1100 | ≤0.95 (Si+Fe) | - | 0.05–0.20 | ≤0.05 | - | ≤0.10 | ≤0.05 | Balance |

| 3003 | ≤0.60 | ≤0.70 | 0.05–0.20 | 1.00–1.50 | - | ≤0.10 | - | Balance |

| 3105 | ≤0.60 | ≤0.70 | ≤0.30 | 0.30–0.80 | 0.20–0.80 | ≤0.40 | ≤0.10 | Balance |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.20–2.80 | ≤0.10 | - | Balance |

Notes: "-" indicates not commonly specified beyond incidental limits. Use mill test certificates for purchase-critical chemistry.

Technical Specifications Customers Commonly Request

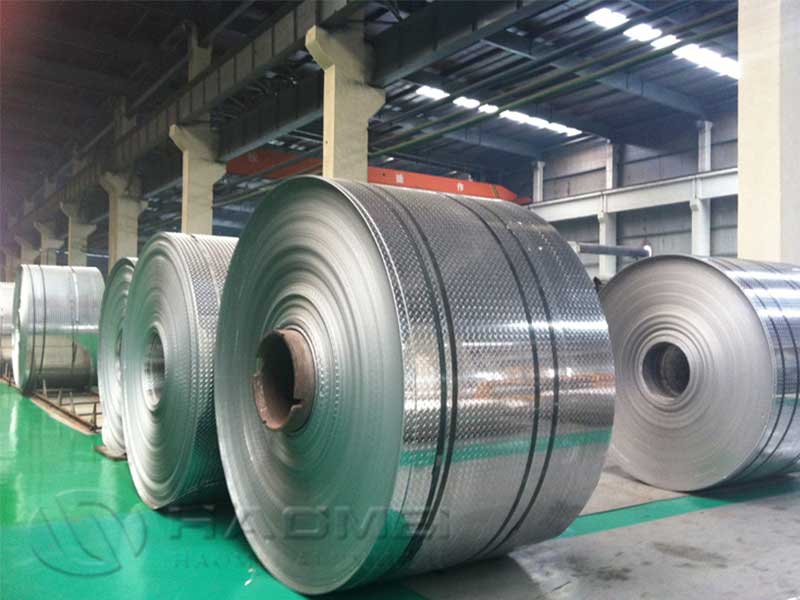

Embossed aluminum is typically supplied in coil or sheet, with temper selected for forming vs. stiffness. Pattern depth and surface finish influence both appearance and forming behavior.

| Parameter | Typical Range / Option | Customer Value |

|---|---|---|

| Thickness | 0.3–3.0 mm (typical), thicker for tread plate | Balances rigidity, weight, and forming |

| Width | 1000–1500 mm common, wider on request | Panel efficiency and fewer seams |

| Length | Cut-to-length or coil | Reduces fabrication time |

| Temper | O, H12/H14, H22/H24, H32 (alloy-dependent) | Controls strength and bendability |

| Surface | Mill finish, anodizing-ready, painted (PVDF/PE), laminated | Appearance and corrosion performance |

| Emboss pattern | Stucco, diamond, five-bar, custom | Grip, scratch masking, design |

| Pattern height | Pattern-dependent; controlled by emboss rolls | Visual depth and functional traction |

| Protective film | Optional | Prevents handling scratches during fabrication |

| Standards | ASTM B209, EN 485/573 (common) | Ensures consistent quality and compliance |

Performance Snapshot (Practical, Shop-Floor Relevant)

Mechanical properties depend strongly on alloy and temper. The values below are typical ranges used for quick comparison.

| Alloy & Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Fabrication Notes |

|---|---|---|---|---|

| 1050-O | 60–100 | 20–35 | 25–40 | Excellent forming; best for deep bends |

| 3003-H14 | 130–180 | 110–160 | 3–10 | Good balance of strength and formability |

| 3105-H24 | 150–200 | 120–170 | 4–10 | Common for painted architectural sheet |

| 5052-H32 | 210–260 | 160–215 | 6–12 | Strong; use appropriate bend radius |

Important: Embossing can slightly alter perceived stiffness and may influence bend appearance. For cosmetic parts, align bend direction with pattern and confirm on a trial piece.

Applications Where Embossed Aluminum Excels

Insulation jacketing and HVAC

Stucco embossed aluminum is a staple for pipe and vessel jacketing, duct cladding, and cold-room insulation covers. The texture reduces glare, hides handling marks from installation, and performs well in outdoor exposure when paired with proper joint sealing.

Transportation interiors and cargo areas

Embossed sheets are used for bus and rail interior panels, van linings, kick plates, and protective covers. Diamond and five-bar patterns are also chosen for floors and steps where slip resistance matters and cleaning needs to be straightforward.

Architectural cladding and rain-screen details

Embossed sheet adds depth to façades, soffits, column wraps, and feature bands. With a PVDF coating or anodizing, it delivers long-term color stability while the texture reduces "flat-panel" monotony and helps conceal minor site damage.

Appliances, equipment housings, and enclosures

For refrigerator liners, washing machine panels, food-service equipment covers, and industrial enclosures, embossed aluminum provides a premium look with better scratch masking than smooth sheet-useful in high-touch, high-cleaning environments.

Packaging equipment and cleanable work areas

Where wash-down, chemical exposure, or frequent wiping is expected, aluminum's corrosion resistance and the sheet's easy-maintenance texture are beneficial. Alloy choice should match the cleaning chemicals and contact environment.

Selection Tips That Reduce Cost and Rework

| Decision Point | What to Consider | Practical Recommendation |

|---|---|---|

| Pattern choice | Grip vs. cleanability vs. aesthetics | Stucco for scratch hiding; diamond/five-bar for traction |

| Alloy | Corrosion environment and strength | 3xxx for general use; 5xxx for marine/industrial |

| Temper | Forming vs. stiffness | O/H12 for heavy forming; H14/H24 for stable panels |

| Coating | UV, chemicals, and color consistency | PVDF for exterior architecture; PE for interior |

| Thickness | Dent resistance and flatness | Increase thickness for large unsupported spans |

| Protective film | Handling and fabrication flow | Use film for cosmetic panels and painted surfaces |

Why Customers Keep Choosing It

Embossed aluminum sheeting offers a rare combination: it looks purposeful, handles real-world wear gracefully, and remains easy to fabricate and maintain. Whether your priority is traction underfoot, a durable architectural texture, or a jacketing material that stays presentable after installation, embossed aluminum provides dependable performance with an upgraded surface that works as hard as the metal beneath it.