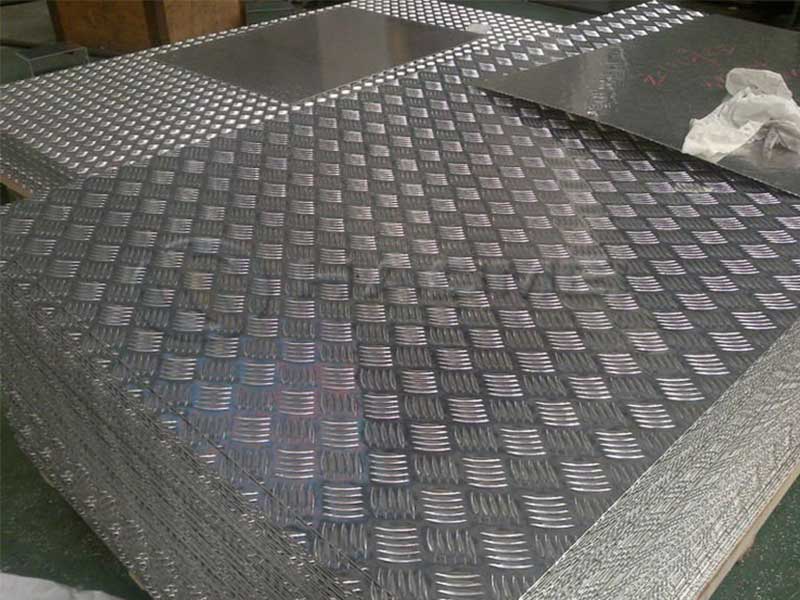

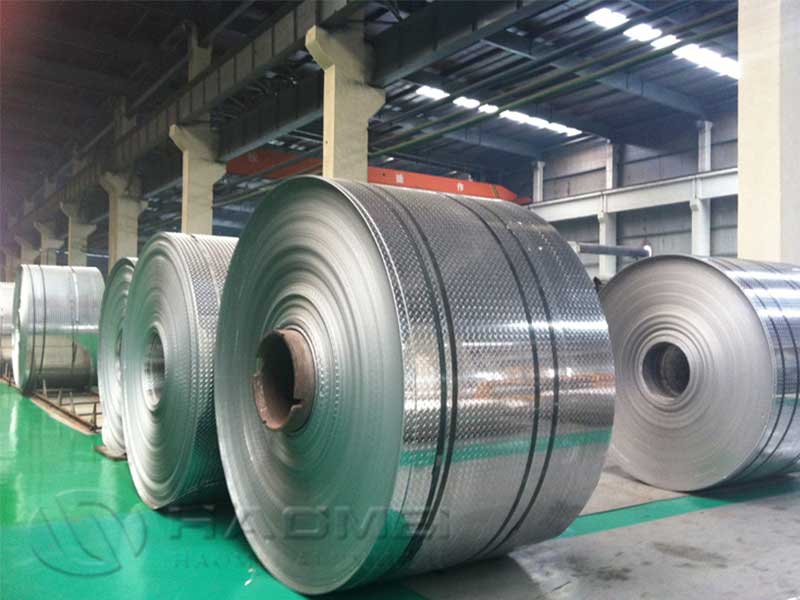

Diamond embossed aluminum sheet plate

Diamond embossed aluminum sheet plate (also known as diamond tread plate or checker plate) is a widely used functional and decorative aluminum product. Its raised diamond pattern not only enhances aesthetics, but more importantly, significantly improves slip resistance, impact resistance, and surface stiffness. This makes it ideal for flooring, walkways, protective cladding, vehicle interiors, and architectural decoration.

Diamond embossed aluminum sheet plate is produced by rolling a flat aluminum sheet through patterned rollers, creating a regular diamond-shaped raised texture on one side. The back side remains relatively smooth, allowing easy installation, welding, or bonding.

characteristics:

- One-side diamond raised pattern, other side flat

- Good anti-slip performance, even when wet or oily

- Lightweight compared to steel checker plate

- Corrosion-resistant and suitable for indoor and outdoor use

- Easy to cut, bend, weld, and form

Common base alloys include 1050/1100/3003/5052/5754/6061, chosen according to strength, corrosion resistance, and processing needs.

2. Typical Chemical Composition

Below are typical chemical composition ranges (mass %) for several frequently used alloys for diamond embossed sheet plate. Actual composition follows relevant standards (EN, ASTM, GB) and mill certificates.

2.1 Chemical Composition Table

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others (each) | Al (approx.) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | – | ≤0.05 | ≤0.03 | ≤0.03 | ≥99.50 |

| 1100 | ≤0.95(Si+Fe) | – | 0.05–0.20 | ≤0.05 | – | – | ≤0.10 | ≤0.05 | ≤0.03 | Balance |

| 3003 | ≤0.60 | ≤0.70 | ≤0.20 | 1.0–1.5 | – | – | ≤0.10 | – | ≤0.05 | Balance |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | ≤0.03 | ≤0.05 | Balance |

| 5754 | ≤0.40 | ≤0.40 | ≤0.10 | 0.30–0.60 | 2.6–3.6 | ≤0.30 | ≤0.20 | ≤0.15 | ≤0.05 | Balance |

| 6061 | 0.40–0.80 | ≤0.70 | 0.15–0.40 | 0.15 | 0.8–1.2 | 0.04–0.35 | ≤0.25 | ≤0.15 | ≤0.05 | Balance |

- 1xxx series (1050, 1100): High purity, excellent ductility, suitable for decorative and light-duty protective uses.

- 3xxx series (3003): Better strength and corrosion resistance than 1xxx, widely used for flooring and cladding.

- 5xxx series (5052, 5754): High corrosion resistance (marine environments), higher strength, suitable for heavy-duty and outdoor applications.

- 6xxx series (6061): Heat-treatable, high strength, used where structural performance is critical.

3. Technical Specifications

3.1 Dimensional Range

Typical standard ranges (custom sizes available):

| Item | Typical Range | Notes |

|---|---|---|

| Thickness (base) | 1.0 – 8.0 mm | Raised pattern adds ~0.3–1.0 mm |

| Width | 1000 – 2000 mm | Common: 1000 / 1220 / 1250 / 1500 mm |

| Length | 2000 – 8000 mm | Cut-to-length available |

| Pattern Height | ~0.7 – 1.5 mm | Depends on thickness and pattern |

| Pattern Type | Single bar / 3-bar / 5-bar / diamond | Diamond is most common |

| Tolerances | As per EN/ASTM/GB or customer drawing | Thickness/flatness/width |

3.2 Mechanical Properties (Typical Values)

Representative values at room temperature (non-design values):

| Alloy & Temper | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation A50 (%) | Brinell Hardness HBW |

|---|---|---|---|---|

| 1050 H14 | 100 – 145 | 60 – 120 | 5 – 12 | ~35 |

| 3003 H14 | 130 – 180 | 115 – 160 | 5 – 10 | ~40 |

| 5052 H32 | 215 – 265 | 160 – 215 | 7 – 12 | ~60 |

| 5754 H22 | 220 – 270 | 130 – 200 | 8 – 12 | ~65 |

| 6061 T6 | 260 – 310 | 240 – 280 | 8 – 12 | ~95 |

Note: Embossing slightly increases apparent surface stiffness but does not dramatically change bulk mechanical properties.

3.3 Physical & Performance Data

| Property | Typical Value (Al Alloys) | Impact on Application |

|---|---|---|

| Density | ~2.70 g/cm³ | About 1/3 weight of steel |

| Melting Range | ~580 – 660 °C | Not for high-temp structural use |

| Thermal Conductivity | 120 – 180 W/(m·K) | Good for heat dissipation, cold storage |

| Electrical Conductivity | 30 – 40 MS/m | Better than most structural metals |

| Coefficient of Expansion | ~23 × 10⁻⁶ /K | Needs allowance for thermal expansion |

| Corrosion Resistance | Good to excellent (esp. 5xxx) | Suitable for marine and outdoor service |

| Slip Resistance (dry/wet) | High (pattern-dependent) | Enhanced safety on walkways and steps |

4. Features & Benefits

4.1 Anti-Slip & Safety Performance

- Raised diamond pattern increases friction coefficient, particularly effective on wet, oily, or dusty surfaces.

- Reduces the risk of slips and falls in industrial environments, vehicle steps, machine platforms, and public traffic areas.

- Pattern geometry disperses water film and contamination, improving surface contact.

4.2 Lightweight Yet Strong

- Aluminum diamond plate offers similar stiffness to thicker flat sheets thanks to the embossed pattern, allowing thickness reduction without losing rigidity.

- Compared with steel checker plate, weight savings can reach 50–70%, lowering structural loads and transportation costs.

- Easier manual handling, reducing installation labor and need for heavy lifting equipment.

4.3 Excellent Corrosion Resistance

- Naturally formed aluminum oxide layer resists rusting without painting in many environments.

- 5xxx marine-grade alloys (5052, 5754) provide superior resistance in coastal, marine, and chemical plant atmospheres.

- Lower maintenance costs: reduced repainting, no rust scaling, and easier cleaning.

4.4 Good Processability

- Can be easily:

- Cut by shearing, sawing, laser, or plasma

- Bent and formed into ramps, covers, and step profiles

- Welded (TIG/MIG) to frames, supports, and structures

- Suitable for post-treatments: anodizing, powder coating, PVDF coating for enhanced appearance and additional protection.

4.5 Aesthetic & Functional Design

- Distinctive metallic appearance with patterned surface enhances visual impact in:

- Architectural facades

- Interior wall cladding

- Commercial counters and display fixtures

- Pattern hides minor scratches and dents better than flat surfaces, maintaining visual quality over longer periods.

5. Typical Applications

5.1 Transportation & Vehicle Industry

| Application Area | Function | Recommended Alloy |

|---|---|---|

| Truck/van flooring | Slip-resistant, wearable load surface | 3003 / 5052 / 5754 |

| Trailer and ramp decks | Anti-slip under load and in rain | 5052 / 5754 |

| Bus and coach steps | Safety steps and doorway sills | 3003 / 5052 |

| Toolboxes & compartments | Durable and decorative outer panels | 3003 / 5052 / 6061 |

| Railway walkway plates | Lightweight access ways and platforms | 5052 / 5754 / 6061 |

5.2 Construction & Architecture

- Flooring & Platforms: Industrial floors, mezzanines, catwalks, maintenance platforms.

- Stair Treads & Landings: Indoor and outdoor stairs, fire escapes, access ladders.

- Wall & Column Protection: Kick plates, corner guards, wall base protection in warehouses and commercial buildings.

- Facade & Interior Decoration: Feature walls, ceilings in public spaces, shopfitting, bar counters.

5.3 Industrial & Equipment Use

| Use Case | Purpose | Remarks |

|---|---|---|

| Machine platforms & walkways | Safe access for operators | Resistant to oil and coolant splashes |

| Equipment covers & guards | Mechanical protection & aesthetics | Light, removable panels |

| Cold rooms & freezers | Anti-slip walkways at low temp | Good performance at sub-zero temps |

| Chemical plants | Corrosion-resistant walkways | Prefer 5xxx alloys |

5.4 Marine & Offshore

- Ship decks (light-duty zones)

- Gangways and ramps

- Engine room platforms

- Dock and marina access steps

Prefer 5052/5754 due to superior resistance to seawater and marine atmosphere.

6. Surface Finish & Coatings

6.1 Standard Mill Finish

- Natural metallic gloss with rolled pattern.

- Suitable for most industrial and utility applications.

- Can be brushed or polished on request.

6.2 Anodized Finish

- Enhanced corrosion resistance and surface hardness.

- Attractive appearance with stable colors (silver, bronze, black, etc.).

- Recommended for architectural and interior design uses.

6.3 Painted / Powder-Coated

- Wide color selection for branding and design alignment.

- Additional protection in harsh chemical or urban environments.

- Often used in public areas where appearance and cleanability are key.

7. Selection Guidelines

When choosing a diamond embossed aluminum sheet plate, consider:

Load & Structural Requirements

- For heavy foot traffic or equipment loads, choose thicker sheets and higher-strength alloys (5052, 5754, 6061).

- For decorative cladding, thinner gauges and 1xxx/3xxx series may suffice.

Environment & Corrosion Conditions

- Indoor dry: 1050, 1100, 3003 are usually adequate.

- Outdoor urban/industrial: recommend 3003, 5052.

- Marine/coastal or chemical: 5052, 5754.

Forming & Fabrication Needs

- Complex bending or deep forming: softer tempers (O, H22, H32).

- Structural frames and welded components: 5052, 5754, or 6061 depending on strength needs.

Aesthetic Requirements

- Visible decorative areas: consider anodized or color-coated surfaces.

- High visibility traffic zones: brighter or contrasting colors for safety.

Diamond embossed aluminum sheet plate combines practical safety performance with attractive design and durability:

- Safety: High slip resistance for floors, ramps, steps, and platforms.

- Lightweight: Significant weight reduction versus steel, easing installation and reducing energy and transport costs.

- Durability: Good corrosion resistance and impact resistance; long service life with minimal maintenance.

- Versatility: Wide range of alloys, thicknesses, and surface finishes for transportation, construction, marine, and industrial applications.

- Processability: Easy fabrication, welding, and forming for customized solutions.

By carefully selecting alloy, thickness, and surface treatment, customers can tailor diamond embossed aluminum sheet plate to match both functional requirements and design expectations, achieving a high-performance, cost-effective, and visually appealing solution across diverse projects.

https://www.al-alloy.com/a/diamond-embossed-aluminum-sheet-plate.html