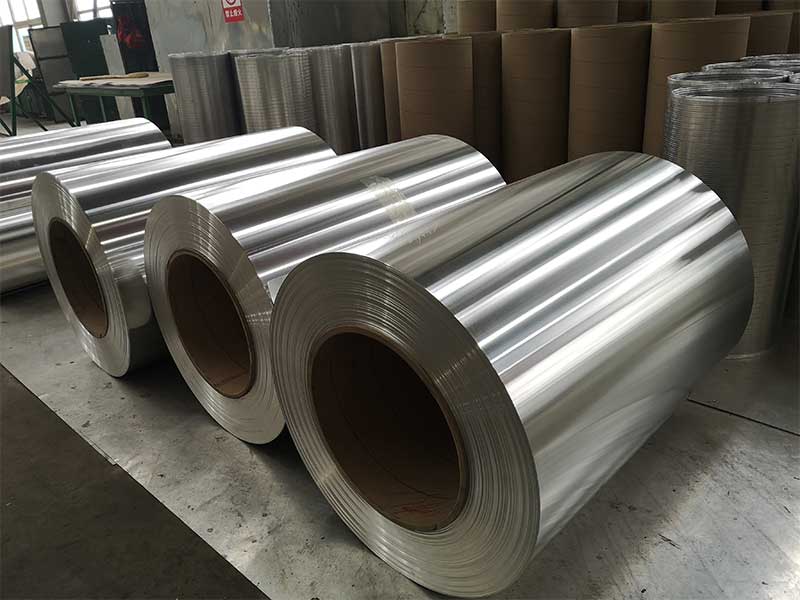

Aluminium coils 3mm

Aluminium coils with a 3mm thickness occupy a sweet spot between strength, formability, and weight. They are widely used across construction, transport, machinery, and decorative industries where flatness, corrosion resistance, and efficient processing are important.

What Are 3mm Aluminium Coils?

A 3mm aluminium coil is a continuous strip of aluminium alloy rolled to a nominal thickness of 3.0 mm and supplied in coil form.

Typical width range:

- Narrow strip for fabrication and profiles

- Medium width for roofing and facade panels

- Wide coil for large-format cladding and industrial sheets

Common tempers include:

- O (annealed, soft)

- H14 / H24 (semi‑hard, work‑hardened)

- H32 / H34 (stronger, controlled strain‑hardened)

- T4 / T6 (solution heat treated and age hardened, mostly for 6xxx series)

Common Alloy Grades for 3mm Coils

Different industries demand different balances of strength, corrosion resistance, and formability. Below is a quick comparison of typical alloy choices for 3mm coils.

Typical Alloy Options

| Alloy Series | Representative Grades | Characteristics | Typical Uses at 3mm Thickness |

|---|---|---|---|

| 1xxx | 1050, 1100 | Very high purity, excellent corrosion resistance, very good formability, low strength | Chemical equipment, decorative trim, reflectors |

| 3xxx | 3003, 3105 | Manganese alloyed, good corrosion resistance, moderate strength, good weldability | Roofing, facades, gutters, insulation jacketing |

| 5xxx | 5005, 5052, 5754 | Magnesium alloyed, high corrosion resistance, good strength, marine capable, weldable | Marine panels, transport, structural cladding |

| 6xxx | 6061, 6082 (coil-plate) | Mg–Si alloyed, heat‑treatable, higher strength, good machinability | Structural parts, machined components, frames |

Example Chemical Composition (Typical)

Exact composition depends on the selected alloy. The following tables show approximate reference compositions for common grades used at 3mm.

Alloy 3003 (Typical Composition, wt%)

| Element | Si | Fe | Cu | Mn | Mg | Zn | Others (each) | Al |

|---|---|---|---|---|---|---|---|---|

| % | ≤0.6 | ≤0.7 | 0.05–0.20 | 1.0–1.5 | – | ≤0.10 | ≤0.05 | Balance |

Alloy 5052 (Typical Composition, wt%)

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Others (each) | Al |

|---|---|---|---|---|---|---|---|---|---|

| % | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | ≤0.05 | Balance |

Alloy 1100 (Typical Composition, wt%)

| Element | Si + Fe | Cu | Mn | Zn | Others (each) | Al |

|---|---|---|---|---|---|---|

| % | ≤0.95 | 0.05–0.20 | ≤0.05 | ≤0.10 | ≤0.05 | ≥99.00 |

These compositions ensure repeatable mechanical performance and excellent surface quality when processed into 3mm coils.

Technical Specifications for 3mm Aluminium Coils

Parameters can be customized, but the following ranges are typical for commercial 3mm coils.

Dimensional Specifications

| Parameter | Typical Range / Value |

|---|---|

| Thickness | 3.0 mm (tolerance usually ±0.05–0.10 mm) |

| Width | 200 – 2,500 mm (standard: 1,000 / 1,250 / 1,500 mm) |

| Coil Inner Diameter | 508 mm or 610 mm |

| Coil Outer Diameter | Usually 1,000 – 1,800 mm (depending on weight) |

| Coil Weight | 1 – 10 metric tons per coil (customizable) |

| Edge Condition | Mill edge or slit edge |

| Surface Finish | Mill finish, brushed, anodized, coated, embossed |

Mechanical Properties (Indicative)

| Alloy / Temper | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation A50 (%) | Typical Use Focus |

|---|---|---|---|---|

| 1100-H14 | 110 – 145 | 95 – 125 | 4 – 10 | Non‑strength, decorative |

| 3003-H14 | 140 – 190 | 120 – 160 | 4 – 12 | General construction |

| 5052-H32 | 210 – 260 | 130 – 180 | 7 – 12 | Marine & transport |

| 5754-H22 | 190 – 240 | 120 – 170 | 8 – 14 | Structural cladding |

Values vary by standard (EN, ASTM, GB) and by supplier; they serve as guidance rather than guaranteed figures.

Physical Properties

| Property | Typical Value Range |

|---|---|

| Density | ~2.70 g/cm³ |

| Melting Point | 580–660 °C (depending on alloy) |

| Thermal Conductivity | 120–160 W/m·K |

| Electrical Conductivity | 28–40 MS/m (higher for 1xxx, lower for 5xxx, 6xxx) |

| Coefficient of Thermal Expansion | ~23 × 10⁻⁶ /K |

| Modulus of Elasticity | ~70 GPa |

Features of 3mm Aluminium Coils

Balanced Strength and Formability

At 3mm thickness, aluminium coils deliver enough rigidity for panels and structural skins while remaining easy to shear, punch, bend, and roll‑form.

- Softer tempers allow deep drawing and complex shaping

- Harder tempers offer better load‑bearing and dent resistance

Excellent Corrosion Resistance

Alloys such as 3003 and 5052 form a dense, self‑healing oxide layer:

|-------------------------|--------------------------------------------------------|| Urban / industrial | Very good, especially with paint or anodizing || Marine / coastal | Excellent with 5xxx series (5052, 5754) || Chemical / process | Good; alloy selection depends on specific medium || Outdoor weathering | Long service life with minimal maintenance |

Lightweight with High Efficiency

Compared with steel at the same thickness, 3mm aluminium can reduce component weight by roughly one‑third:

| Material | Density (g/cm³) | Relative Weight at Same Volume |

|---|---|---|

| Steel | ~7.85 | 100% |

| Aluminium | ~2.70 | ~34% |

This weight advantage is vital for transportation, suspended ceilings, facade systems, and equipment that needs easier handling during installation.

Versatile Surface Options

3mm aluminium coils are available in multiple surface treatments:

| Treatment Type | Description / Benefit |

|---|---|

| Mill finish | As‑rolled, suitable for further processing |

| Anodized | Hard, wear‑resistant, decorative oxide layer, various colors |

| PVDF coated | High‑durability architectural coating, excellent UV resistance |

| Polyester coated | Cost‑effective color coating for general outdoor use |

| Embossed | Stucco, orange‑peel, and other textures for aesthetics & stiffness |

| Brushed / polished | Decorative, high‑end appearance and improved reflectivity |

Typical Applications of 3mm Aluminium Coils

Building and Architectural Uses

3mm is a favored thickness in building envelopes and decorative elements:

| Application Area | Role of 3mm Aluminium Coil |

|---|---|

| Facade cladding panels | Base material for flat or cassette panels, perforated panels |

| Roofing and soffits | Durable, lightweight sheets for roofs and eaves |

| Curtain wall back panels | Structural backing for composite or glass systems |

| Rainwater systems | Gutters, downpipes, flashings, valley trays |

| Interior decoration | Ceilings, wall panels, column covers, screen panels |

Advantages in construction include corrosion resistance, ease of cutting on‑site, and compatibility with common fastening and sealing systems.

Transportation and Automotive

3mm coils are widely processed into parts for trucks, trailers, buses, and rail:

| Component Type | Function of 3mm Aluminium Material |

|---|---|

| Body side panels | Lightweight but stiff outer skins |

| Floor and step plates | When combined with tread patterns for higher stiffness |

| Toolboxes and enclosures | Corrosion‑resistant housings for equipment |

| Interior linings | Protects structure, easy to clean |

Weight reduction directly supports higher payload, lower fuel consumption, and easier handling.

Marine and Offshore

Marine‑grade alloys in 5xxx series are especially suited for salty environments:

| Marine Use Case | Features of 3mm Alloy Coil in Service |

|---|---|

| Boat hull skins (small craft) | Good formability for curved shapes and hull plating |

| Deck sheathing | Slip‑resistant patterns possible, high corrosion resistance |

| Superstructures | Weight saving in upper structures, improved stability |

| Dockside equipment | Long‑lasting protection against spray and splash zones |

Industrial and Equipment Fabrication

In general fabrication, 3mm coils are cut and formed into parts with predictable behaviour:

| Sector | Example Products |

|---|---|

| HVAC & insulation | Ducting, cladding for tanks and pipes |

| Electrical enclosures | Boxes, cabinets, covers |

| Machinery guards | Protective covers, panels, safety guards |

| Signage and display | Signboards, light box panels, exhibition structures |

Processing and Fabrication Notes

Working with 3mm aluminium coils is straightforward with standard metalworking equipment.

Forming and Bending

| Operation Type | Suitability at 3mm Thickness |

|---|---|

| Shearing | Clean cuts with standard guillotine shears |

| Punching | Efficient for holes and slots; use proper clearance and tooling |

| Bending | Air‑bending and bottoming common; inner radius set by alloy/temper |

| Roll‑forming | Widely used for long panels, profiles, and channels |

Softer tempers (O, H14) allow tighter radii; harder tempers require larger bend radii to avoid cracking.

Welding and Joining

| Joining Method | Comments for 3mm Aluminium |

|---|---|

| TIG / MIG | Suitable for 3xxx and 5xxx alloys; choose appropriate filler wire |

| Resistance welding | Possible for thin sections; mainly for specific applications |

| Riveting | Common in construction panels and transport structures |

| Adhesive bonding | Effective in facade, signage, and composite panel systems |

Pre‑cleaning of the oxide layer and good joint design are critical for reliable welded connections.

Quality, Standards, and Customization

3mm aluminium coils are typically produced in accordance with international standards such as:

| Standard Family | Examples |

|---|---|

| ASTM | ASTM B209, B209M |

| EN / ISO | EN 485, EN 573, EN 13523 (for coatings) |

| GB / JIS | GB/T 3880, JIS H4000 series |

Common custom options include:

| Customization Aspect | Available Choices |

|---|---|

| Alloy & temper | 1100, 3003, 5052, 5754, 6061; O to H36, T4/T6 |

| Coil width & weight | Cut‑to‑width slitting, specific coil masses |

| Surface finish | Mill, anodized, color coated, embossed, protective film |

| Tolerances | Tight thickness, flatness, and width control |

Aluminium coils in 3mm thickness offer a well‑balanced combination of formability, mechanical strength, low weight, and corrosion resistance. Proper alloy and temper selection allows these coils to serve roles ranging from architectural facades and roofing, through transport bodywork and marine applications, to industrial enclosures and decorative elements.

With appropriate surface treatments and precise fabrication, 3mm aluminium coils provide long‑lasting, visually appealing, and cost‑effective solutions across numerous industries.