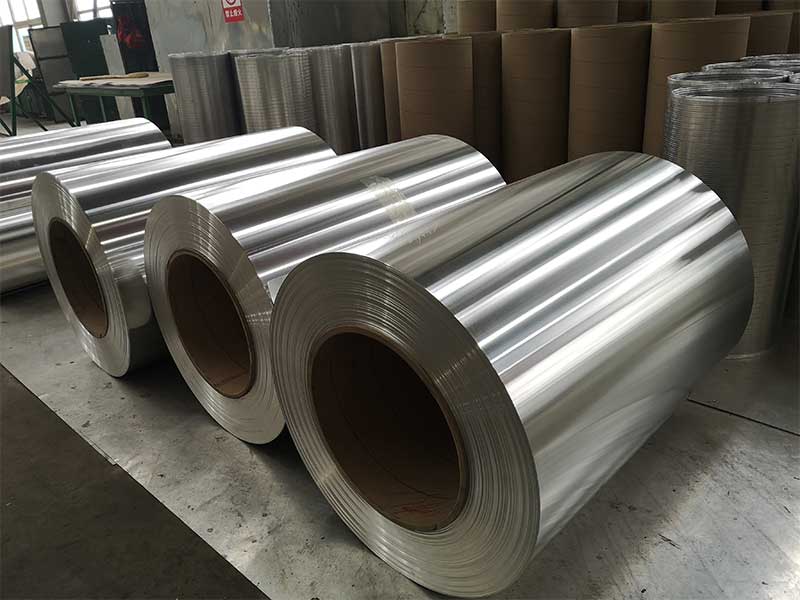

Mill Finished Aluminium Coils for Building Materials

Mill finished aluminium coils are essential raw materials extensively used across the building industry. Known for their natural finish obtained straight from the rolling mill, these coils offer unparalleled versatility, durability, and aesthetic potential when incorporated into construction applications.

Mill Finished Aluminium Coils

Mill finished aluminium coils differ from anodized or painted sheets in that they do not undergo additional surface treatments after the rolling process. This raw state showcases the natural metallic silver-grey appearance of aluminum, highlighting its unaltered durability, light weight, and corrosion-resistant properties.

One of the main advantages of mill finished coils is their excellent machinability and forming capacity. They are suitable for paint or powder coating, rendering them highly customizable for architects and builders with specific design requirements. As a lightweight substitute for heavier metals like steel, aluminium reduces structural loads and improves energy efficiency in buildings.

Functions in Building Materials

The core functions of mill finished aluminium coils in the building industry include:

Structural Support: Aluminium coils contribute by being formed into beams, frames, and other supportive components, providing strength while maintaining lightweight attributes.

Facade and Cladding: When coated or laminated, these coils act as external facades, offering weather resistance and aesthetic versatility.

Roofing Materials: Their resistance to corrosion and excellent thermal conductivity make them ideal for roofing sheets and panels.

Decorative Elements: The smooth finish of mill coils provides an ideal base for decorative treatments that enhance building interiors and exteriors.

Thermal and Electrical Components: Aluminium's innate properties enable usage where heat conduction and electrical performance are crucial.

Common Applications in Construction

Mill finished aluminium coils are applied extensively in several sectors of the building industry:

Window and Door Frames: Lightweight and structurally sound, integrating coils into HTML-convertible frameworks improves stability and lifespan.

HVAC Systems: HVAC ducts and components benefit from aluminium's corrosion resistance and thermal efficiency.

Wall Partitions: Panels formed from these coils ensure durability without compromising on the building’s weight or safety.

False Ceilings: Used frequently in suspended ceiling applications given their easy fabrication and stylish finishing post-treatment.

Elevator and Escalator Components: The metallic sheen and corrosion resistance complement the structural needs of vertical transit systems in buildings.

Technical Specifications and Standards

To achieve optimal performance, mill finished aluminium coils comply with stringent implementation standards and technical parameters.

| Parameter | Detail |

|---|---|

| Alloy Types | 1000 series (pure aluminium), 3000 series (aluminium-manganese), 5000 series (aluminium-magnesium) |

| Temper Conditions | O (annealed), H14 (half hard), H16 (quarter hard) |

| Thickness Range | 0.2mm - 3.0mm |

| Width Range | 100mm - 2000mm |

| Standard Lengths | Customized, typically 1000m+ |

| Surface Finish | Mill finished (natural metallic with minor mill marks) |

Implementation Standards:

- ASTM B209: Specification for Aluminium and Aluminium Alloy Sheet and Plate

- EN 573-3: Aluminium and Aluminium Alloys – Chemical Composition and Forms

- GB/T 3880: National Chinese Aluminium Coil Standard

Alloy Chemical Composition

Aluminium coil selection depends heavily on alloy properties which link directly to mechanical and chemical performance. The most commonly used mill finished alloys for building materials belong to the 1000, 3000, and 5000 series, each offering distinct advantages. Below is the chemical composition table for prime alloys.

| Alloy | Al (%) | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Ti (%) | Others (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1050 | ≥ 99.5 | ≤ 0.25 | ≤ 0.4 | ≤0.05 | ≤ 0.05 | ≤ 0.03 | ≤ 0.05 | ≤ 0.03 | ≤ 0.03 |

| 3003 | ≥ 96.8 | ≤ 0.6 | ≤ 0.7 | ≤ 0.05 | 1.0-1.5 | ≤ 0.1 | ≤ 0.1 | ≤ 0.15 | ≤ 0.15 |

| 5005 | ≥ 97.0 | ≤ 0.6 | ≤ 0.7 | ≤ 0.1 | ≤ 0.2 | 0.8-1.2 | ≤ 0.1 | ≤ 0.1 | ≤ 0.15 |

Alloy Tempering Conditions Explained

Temper determines a coil’s hardness and ductility, setting how it will behave in construction applications.

| Temper | Description | Functionality |

|---|---|---|

| O | Annealed (soft) | Ideal for applications needing extensive forming and bending |

| H12 | Quarter hard | Marks beginning of significant strength and resistance to deformation |

| H14 | Half hard | Common choice for structural elements resisting deformation |

| H16 | Three-quarter hard | Exhibits higher strength for heavier load-bearing applications |

In building, choosing the right temper ensures the coil matches installation demands without compromising performance or aesthetic finish during handling and use.

Advantages for Construction Projects

Mill finished aluminium coil offers multiple inherent benefits for building applications:

- Corrosion Resistance: Natural oxide layer forms instantly, protecting the coil against rust and atmospheric corrosion.

- Lightweight: Significantly lowers structure weight compared to steel, aiding ease of transport and installation.

- Excellent Workability: Capable of cutting, folding, and rolling into complicated shape profiles.

- Sustainable and Recyclable: 100% recyclable product resulting in eco-friendlier building implementations.

- Cost-Efficient: Lower maintenance expense throughout a building’s service life compared to other metals.

https://www.al-alloy.com/a/mill-finished-aluminium-coils-for-building-materials.html