Polished mirror aluminum coil

When you hear “polished mirror aluminum coil,” you probably picture something ultra shiny—a surface so reflective you nearly see your own face. And you wouldn’t be wrong. But this isn’t just about aesthetics. Behind that gleaming facade lies a practical, versatile metal that keeps popping up in industries you might not immediately connect with it.

So, what exactly makes polished mirror aluminum coil special? L

What’s Under the Shine?

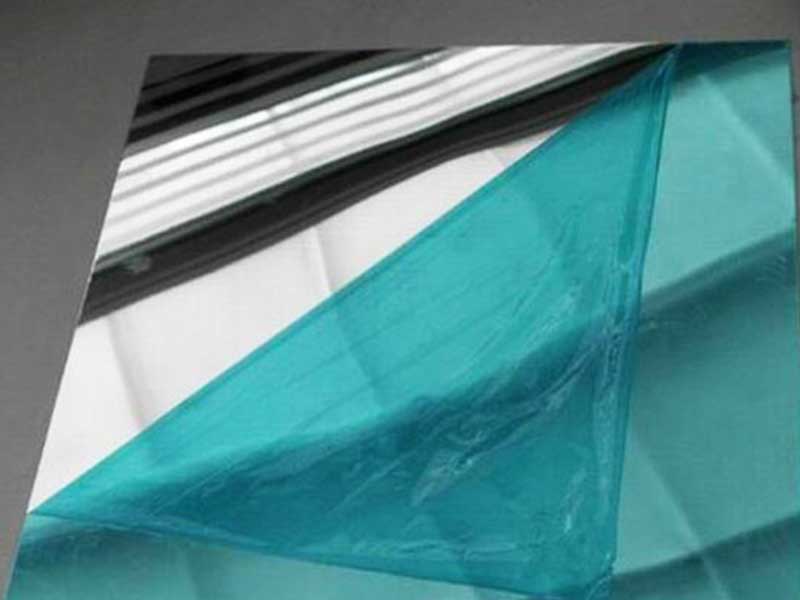

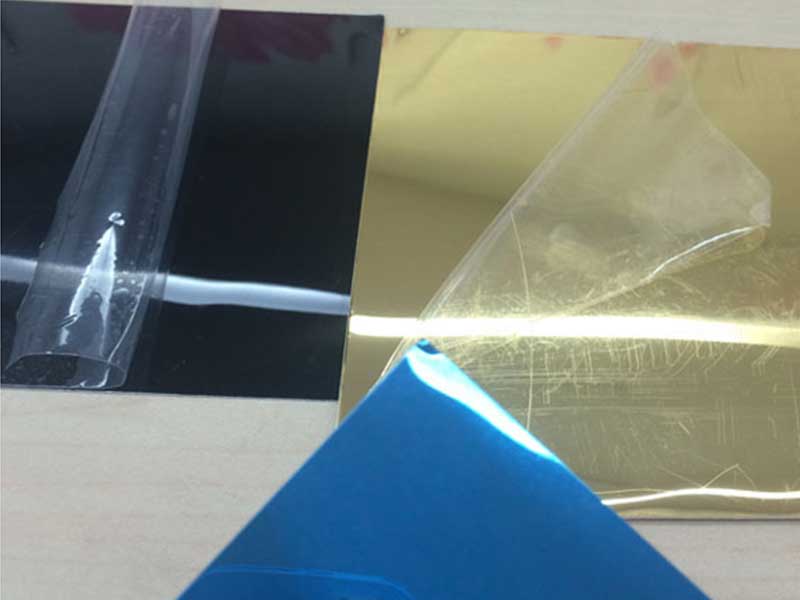

At its core, polished mirror aluminum coil is just aluminum sheet or strip that’s been run through a serious polishing process until the surface is ultra smooth and reflective like a mirror. This isn’t your everyday brushed or dull aluminum—it’s got a level of polish that can reflect light clearly and sharply.

The here? Precision. Polishing removes any microabrasions and surface roughness that could scatter light or, worse, promote corrosion pockets. In some cases, electro-polishing is used to combine smoothing with a slight brightening of the metal simply by controlled chemical removal of surface layers. The difference from regular finished aluminum coil is stark—the polished mirror coil literally shines with minimal distortion.

Functional Benefits: Beyond the Gloss

Reflectivity for EfficiencyWhile it looks fantastic, the high reflectivity has practical upsides. Think heat management. Reflective surfaces can bounce back infrared radiation (heat) efficiently. This principle makes it very useful in HVAC systems or thermal shielding where controlling temperature means energy-saving and longer equipment life.

Corrosion ResistanceA smooth, polished surface reduces the clad spots for dirt, moisture, and corrosive agents. When combined with high-grade aluminum alloys like 3003 or 5005 that have natural corrosion protection, the mirror finish extends material lifespan outdoors or in humid environments.

Easy to Clean and Maintain

A signaling or safety accessoryIts reflective quality isn’t only useful indoors. Roadside markings, emergency signs, or safety panels sometimes employ these coils (or laminates thereof), using mirror-like platforms to catch vehicle headlights or flash light signals, improving visibility at night or under harsh weather.

Where Do You Actually See It?

Polished mirror aluminum coag is like the unsung hero in many applications that call not just for durability but also an aesthetic punch or high-performance surface!

Elevators and Escalators: Step inside any shiny lift cabin and spot polished aluminum panels lining walls or ceilings. It’s the expensive-looking metal that avoids fingerprints and visually expands space with light reflection.

Appliance Fronts: High-end refrigerators, microwave panels, and small kitchen appliances use sealed polished aluminum MTB (mirror) coils for a sleek look that beats stainless steel in weight and rust resistance.

Architectural Decor: Whether on interior walls, column wraps, or light holders, mirror finish adds that sleek modern touch while posing less risk of scratches becoming obvious due to smart alloy composing combined with thin coatings.

Automotive trims: Where lightweight mock-chrome or faux-metallic parts are in demand, polished mirror voting-aluminum wraps provide that showroom-gloss look but with real aluminum cutback weights.*

Reflectors and Lighting Fixtures: Mirrored coil forms perfect back plates or reflectors that stay shiny indefinitely while evenly bouncing light onto rooms — important for maximizing energy-efficient lightbulbs' output.

What’s Different In Manufacturing?

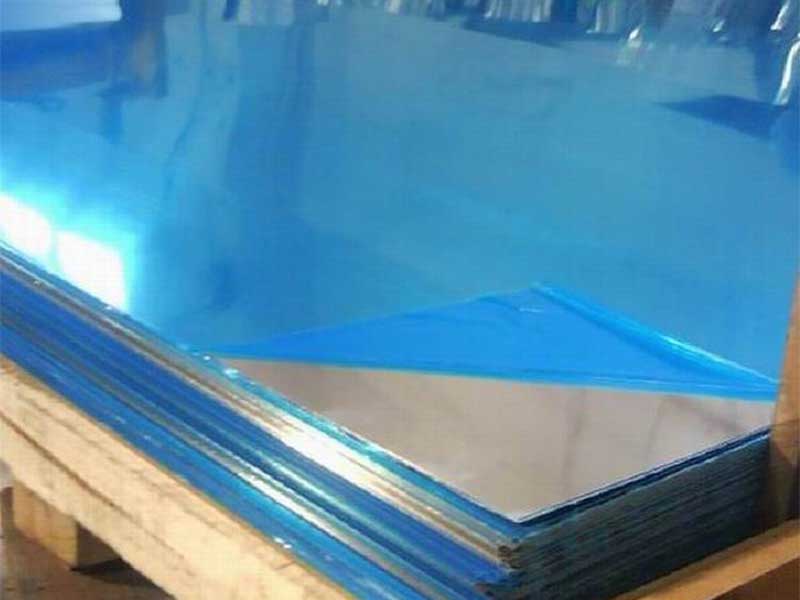

Compared to standard mill-finished or painted aluminum coils, the polishing process adds steps and care. Maintaining a consistent thickness is crucial, as the polishing slightly removes metal. Also, resistivity and microcracking risks need to be factored in while selecting alloys and polishing media.

Suppliers often offer customized thickness ranges (commonly between 0.3 to 0.6 mm) to balance strength with bendability for easy fabrication. Quality controls measure surface deviation, reflectance percentage (often exceeding 85-90% in visible ranges), and corrosion under accelerated testing patterns.

Wrapping Up

Polished mirror aluminum coil isn’t just shiny flair. It’s a technically robust, multipurpose material chosen for a blend of defense against the elements, visual impact, and specialists functions like light reflection or hygiene compliance. Next time you see that intact mirror-like sheet or panel gleaming effortlessly, you’ll know there’s a silent story of technique and benefit behind the sparkle—not just pretty light tricks.

Light, strong, reflective, and practical—a polished mirror aluminum coil quietly shaping many modern spaces with style and substance. Sometimes versatility comes looking glassy fabulously.

https://www.al-alloy.com/a/polished-mirror-aluminum-coil.html