Anodized aluminum sheet 5058 5082 5083 5251 H321 H116

Anodized aluminum sheets in alloys 5058, 5082, 5083, and 5251 offer exceptional corrosion resistance, enhanced surface durability, and increased aesthetic appeal, widely used in marine, automotive, architectural, and industrial fields. Combined with temper designations H321 and H116, these materials deliver superior performance under demanding conditions.

These alloys belong primarily to the 5xxx aluminum series, which is aluminum-magnesium based. They are characterized by excellent corrosion resistance, good weldability, and moderate to high strength, making them preferred choices in marine, corrosive, and structural applications.

| Alloy | Primary Elements (%) | Features |

|---|---|---|

| 5058 | Mg (4.5–5.5), Si (0.3 max), Fe (0.4 max) | Excellent corrosion resistance; good mechanical strength |

| 5082 | Mg (3.8–4.9), Si (0.4 max), Fe (0.4 max) | High strength with superior corrosion resistance |

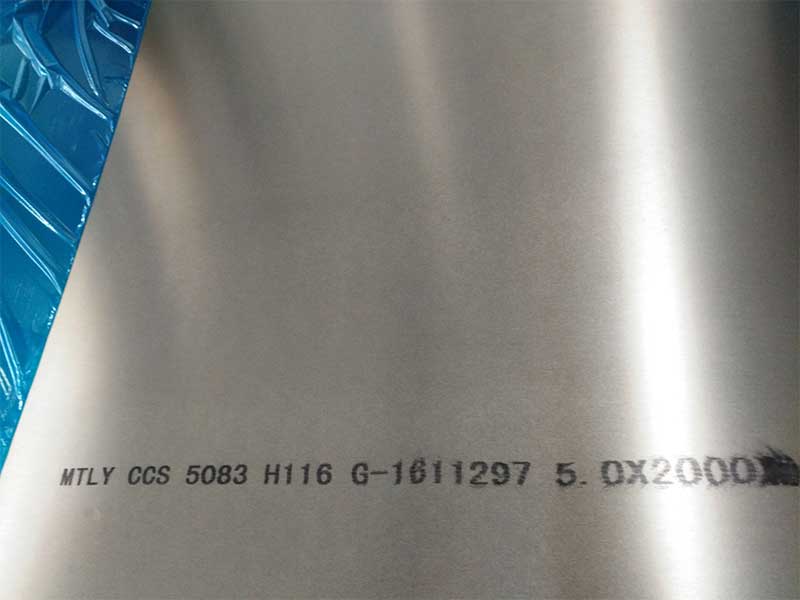

| 5083 | Mg (4.0–4.9), Mn (0.4–1.0), Fe (0.4 max) | Excellent corrosion resistance especially in marine environments; good weldability |

| 5251 | Mg (2.5–3.5), Si (0.25 max), Fe (0.4 max) | Good formability and corrosion resistance |

Chemical Composition Tables (Typical) by Alloy (%)

| Element | 5058 | 5082 | 5083 | 5251 |

|---|---|---|---|---|

| Aluminum | Balance | Balance | Balance | Balance |

| Magnesium (Mg) | 4.5–5.5 | 3.8–4.9 | 4.0–4.9 | 2.5–3.5 |

| Manganese (Mn) | 0.2 max | 0.2 max | 0.4–1.0 | 0.1 max |

| Silicon (Si) | 0.3 max | 0.4 max | 0.4 max | 0.25 max |

| Iron (Fe) | 0.4 max | 0.4 max | 0.4 max | 0.4 max |

| Copper (Cu) | 0.1 max | 0.1 max | 0.1 max | 0.1 max |

| Chromium (Cr) | 0.05 max | 0.05 max | 0.05 max | 0.05 max |

Note: Composition can slightly vary with production processes and standards.

Temper Designations: H321 and H116

H321

- Definition: Cold worked section, stabilized by partial annealing. The “3” indicates strain hardened and solution heat-treated, and the “21” shows strain relief.

- Attributes: This temper offers improved mechanical strength compared to fully annealed temper (O temper) but maintains corrosion resistance suitable for severe environments. It is normally used for marine-grade sheets and environments with cyclic stress.

H116

- Definition: Solution heat treated and naturally aged. Certified for seawater corrosion resistance.

- Attributes: High resistance to plate cracking during welding and inferior corrosion susceptibility. Primarily used in weldable and corrosion-prone structures, especially in shipbuilding.

Anodizing Process and Benefits

Anodizing is an electrochemical process that thickens the natural oxide film on the surface of aluminum sheets providing:

- Enhanced Corrosion Resistance: Protection for the base material against oxidation in highly reactive or saltwater environments.

- Increased Surface Hardness: Improved wear resistance that enhances lifespan under abrasive applications.

- Aesthetics: Variety of finishes including matte, bright, or colored options.

- Excellent Adhesion: Ensures superior base for painting or printing.

- Environmental Safety: Anodizing does not emit harmful chemicals and supports sustainability in manufacturing.

Mechanical Properties (Typical) – According To Alloys and Temper (Example per ASTM B209 / AMS 4014 standards)

| Property | 5058-H321 | 5082-H321 | 5083-H116 | 5251-H116 |

|---|---|---|---|---|

| Ultimate Tensile Strength (MPa) | 290 – 350 | 280 – 340 | 275 – 355 | 215 – 270 |

| Yield Strength (0.2% offset, MPa) | 200 – 270 | 200 – 265 | 145 – 300 | 150 – 220 |

| Elongation (%) | 8 – 15 | 10 – 18 | 7 – 14 | 18 – 28 |

| Rockwell Hardness (B) | 75 – 90 | 80 – 95 | 70 – 92 | 60 – 70 |

| Density (g/cm³) | ~2.66 | ~2.66 | ~2.66 | ~2.68 |

Conformance and Implementation Standards

| Standard | Description |

|---|---|

| ASTM B209 | Aluminum and aluminum-alloy sheet and plate specifications |

| AMS 4014 | Anodized aluminum alloy sheet elaboration and requirements |

| QQ-A-250 / MIL-A-8625 | Anodizing of aluminum and aluminum alloys (military spec) |

| EN AW 5058, 5082, 5083 | European alloy designations consistent with EN 573-3 standards |

| GB / JIS Specifications | Relevant Chinese and Japanese industrial standards |

Adherence to these ensures consistent sheet thickness, flatness, surface finish, mechanical performance, and coating uniformity.

Applications

- Marine Industry: Boat components, ship hull plating, decking — due to excellent resistance to saltwater corrosion.

- Architectural Paneling: Lightweight facade cladding & decorative panels that require wear-resistance and longevity.

- Automotive Components: Bodywork and structural elements designed for anti-corrosion and strength.

- Electrical Equipment Casings: Aluminum enclosures, managed with superior durability and flexible finishing.

- Pressure Vessels and Tanks: Where anodizing and corrosion resistance is critical for safety.

Anodized aluminum sheets made from alloys 5058, 5082, 5083, and 5251, in H321 and H116 tempers, represent a state-of-the-art solution for projects needing a fine balance of high mechanical strength causality and advanced corrosion resistance. The anodizing process amplifies the natural strengths of these materials, positioning them at the forefront of industries needing durability, reliability, and aesthetic versatility.

For inquiry or more technical information about anodized aluminum sheets in specified alloys and tempers, please contact us. Our engineering team is ready to assist you with tailored solutions for your application needs.

https://www.al-alloy.com/a/anodized-aluminum-sheet-5058-5082-5083-5251-h321-h116.html