Aluminium sheet insulation

Aluminium sheet insulation stands out as a versatile material across industries that demand lightweight, durable, and effective thermal management solutions. From construction to HVAC systems, it plays a crucial role in energy efficiency and protection.

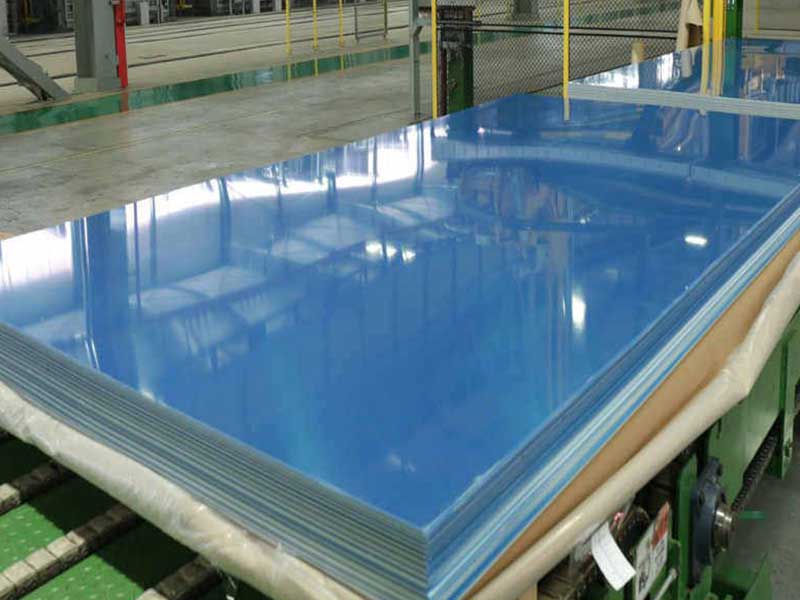

Aluminium Sheet Insulation

Aluminium sheet insulation primarily serves as a reflective barrier that limits heat transfer through radiation, conduction, and convection. Its excellent thermal reflective properties make it an ideal candidate for insulation blankets, panels, and wraps used extensively in buildings and industrial settings.

Aluminium’s high thermal conductivity might suggest poor insulation, but when paired with other insulating materials, the reflective surface effectively reduces heat gain or loss, creating energy-efficient environments. Furthermore, aluminium sheets act as moisture barriers and resist corrosion, ensuring long service life even under challenging environmental conditions.

Functions:

| Function | Description |

|---|---|

| Thermal Reflectivity | Reflects up to 95% of radiant heat |

| Vapor and Moisture Barrier | Prevents dampness, reducing condensation risks |

| Durability | Resists corrosion, abrasion, extending lifespan |

| Lightweight | Minimizes additional load, ideal for retrofitting |

| Fire Resistance | Non-combustible nature enhances fire safety |

Applications of Aluminium Sheet Insulation

Aluminium sheet insulation is utilized in various sectors for comprehensive thermal and environmental protection:

- Building & Construction: Used in roofing membranes, vapor retarders, and radiant barriers to improve residential and commercial building energy performance.

- HVAC Systems: Insulates ducts and pipes, preventing heat loss and condensation, boosting heating and cooling efficiency.

- Automotive & Aerospace: Lightweight aluminium sheet insulation aids thermal protection in vehicle interiors and engine compartments.

- Industrial Equipment: Applied in tanks, boilers, and machinery to maintain temperature stability and safeguard components.

- Packaging: Reflective insulation for cold storage and thermal packaging solutions to preserve goods across transportation.

Technical Specifications and Implementation Standards

The aluminium sheets used in insulation must align with specific standards to ensure quality, safety, and efficiency. These guide physical, chemical, and mechanical properties as well as appropriate installation methods.

| Parameter | Specification / Standard | Description/Rationale |

|---|---|---|

| Sheet Thickness | 0.016 mm – 0.500 mm | Varies depending on application and required durability |

| Typical Width | 1000 mm – 1600 mm | Makes coverage and handling consistent |

| Reflectivity | ≥ 90% (ASTM C1371 Method) | Confirms effective thermal radiation reflection |

| Tensile Strength | 90–310 MPa (dependent on alloy) | Indicates mechanical robustness during installs |

| Compliance Standards | ASTM B209, EN 573-3, ISO 6361 | International standards certifying manufacturing quality |

| Fire Rating | Class A / Euroclass A1 / NFPA 255 | Non-combustible test results ensuring safety compliance |

Choosing aluminium proprietary coatings or laminates is common to enhance properties such as UV resistance or flame retardation based on application needs.

Aluminum Alloy Type, Temper, and Chemical Composition

Thermal insulation sheets are typically tailored from commercially pure aluminium or aluminium alloys, offering different hardness levels and mechanical strengths through temper treatments.

| Alloy | Temper | Application | Properties |

|---|---|---|---|

| 1100 (Pure) | O | Reflective barriers, wrapping | Excellent corrosion resistance, high ductility |

| 3003 | H14 | Roofing membranes, cladding | Good strength, moderate corrosion resistance |

| 5052 | H32 | Industrial equipment insulation | Higher strength, good corrosion resistance |

| 8011 | H24 | Household insulation and packaging | Easily lacquered; polished surface |

Typical Chemical Composition (% by weight)

| Element | 1100 Alloy | 3003 Alloy | 5052 Alloy | 8011 Alloy |

|---|---|---|---|---|

| Aluminium | 99.0 min | 97.0 min | 94.8 – 96.8 | 95.5 – 97.5 |

| Copper | 0.05 max | 0.05 max | 0.10 max | 0.15 max |

| Manganese | 0.05 max | 1.0 – 1.5 | 0.10 max | 0.3 – 0.6 |

| Magnesium | 0.03 max | 0.05 max | 2.2 – 2.8 | 0.10 max |

| Silicon | 0.95 max | 0.6 max | 0.4 max | 0.4 max |

| Iron | 0.95 max | 0.7 max | 0.4 max | 0.5 max |

| Zinc | 0.25 max | 0.1 max | 0.1 max | 0.15 max |

Installation and Performance Tips

Ensuring the optimal results from aluminium sheet insulation requires appropriate handling and installation:

- Maintain dryness before installation to prevent moisture entrapment.

- Use vapor barriers suitable for the surround environment to complement aluminium’s reflective performance.

- Proper overlap and sealing reduce air infiltration and enhance insulation continuity.

- Examine alloy choice against localized environmental factors such as humidity, chemical exposure, or mechanical wear.

- Regular inspection post-installation ensures the insulating layer remains intact and effective.

Aluminium sheet insulation offers an excellent balance of reflective efficiency, physical durability, and corrosion resistance essential in managing thermal dynamics across varied sectors. With adaptable alloy recipes and temper conditions, these sheets conform strictly to high manufacturing standards, ensuring reliable performance in energy saving and long-lasting installation integrity.

Whether cutting energy bills, protecting equipment, or extending infrastructure lifespan, aluminium sheet insulation remains an essential component in modern thermal management solutions.

Optimizing your construction or industrial projects with aluminium sheet insulation delivers tangible benefits—dropping heat transfer, adding durability, and bolstering overall environmental resistance. Selecting the right alloy and thickness with certified quality is crucial for maximizing this product's capabilities and ensuring its role as an outstanding insulation medium.

For detailed inquiries or custom solutions, feel free to contact your trusted aluminium sheet insulation supplier and expertise professional.