Marine Aluminium Plate 5083 5059 6082

Shipbuilders and offshore engineers rarely talk about aluminium plate the way it deserves to be discussed. The conversation often starts with thickness, price, or lead time, and only later wanders toward what actually keeps a hull quiet in rough seas, what lets a deckhouse stay straight after years of vibration, or what prevents a welded joint from becoming the first place corrosion decides to settle. A more useful way to look at marine aluminium plate is as a set of "roles" you cast into a vessel: one alloy to carry loads while staying weld-friendly, one alloy to resist seawater with calm confidence, and one alloy to behave predictably in machined, bolted, and stiffened structures. From that perspective, 5083, 5059, and 6082 feel less like competing grades and more like three specialists that cover most of the marine script.

Why "marine" aluminium is more than corrosion resistance

Marine service is a combination of chloride exposure, wet-dry cycling, crevice conditions under sealants, and the mechanical reality of repeated wave loading. Aluminium survives this environment when its microstructure and alloying system resist localized attack, and when fabrication practices avoid sensitization and poor weld profiles. Plate selection should therefore be tied to how the structure is made: welded or bolted, thick or thin, highly stressed or lightly loaded, constantly wet or intermittently splashed.

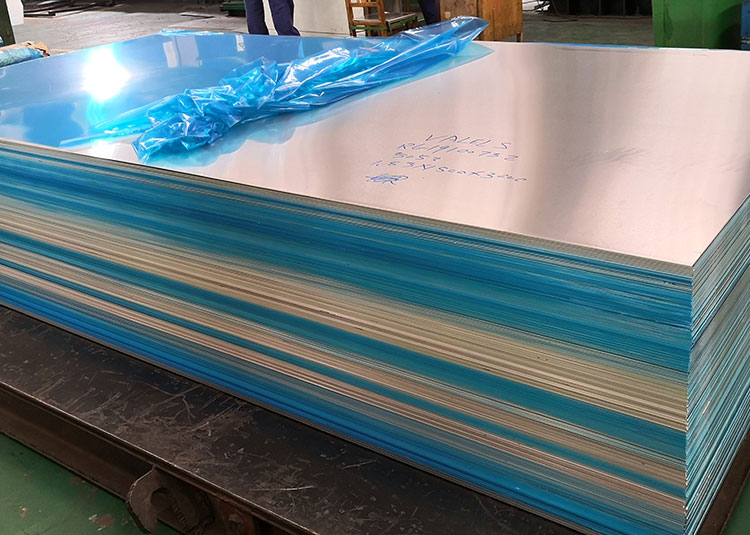

Implementation standards help translate the environment into practical purchasing requirements. Commonly used references include EN 485 for aluminium plate tolerances and mechanical properties, EN 573 for chemical composition, and classification society rules such as DNV, ABS, Lloyd's Register, and Bureau Veritas for marine construction. In North America, ASTM B209 is the familiar specification for aluminium sheet and plate. When you buy "marine grade" plate, you are usually buying a combination of alloy, temper, inspection expectations, and traceability that satisfies these standards.

5083: the quiet workhorse for welded hull structures

If marine aluminium has a default language, 5083 speaks it. As an Al-Mg-Mn alloy, it is built for corrosion resistance and weldability, and it offers a reliable balance of strength and ductility in plate form. In real projects, 5083 is often chosen because it forgives the messy parts of building: fit-up variations, long weld runs, and the inevitable design changes that happen once a vessel meets real-life constraints.

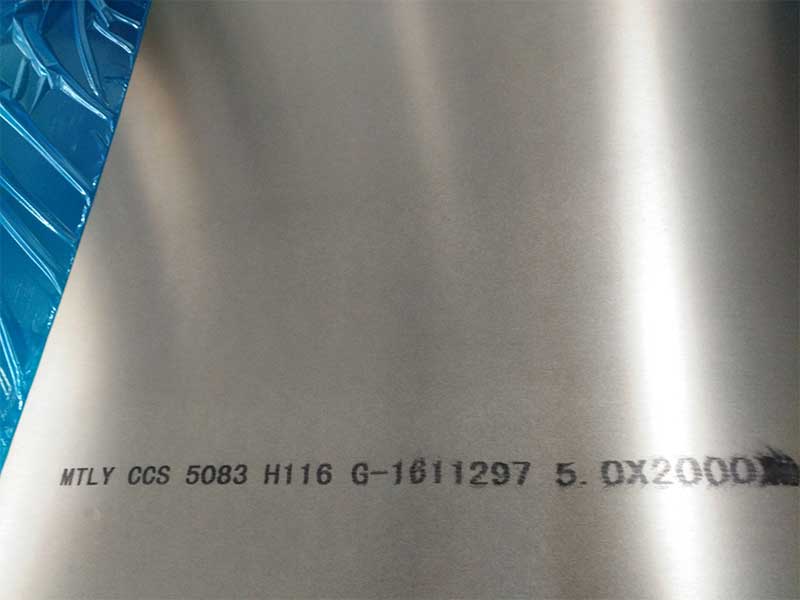

Typical tempers for marine plate are H116 and H321. These are not "heat treated" the way 6xxx alloys are; they are strain-hardened and stabilized. The point of these tempers is to provide good strength while controlling susceptibility to intergranular corrosion in service. For hull plating and superstructures that will be welded extensively, 5083-H116 is a common, conservative selection, especially in thicker gauges.

A practical note from fabrication: 5083 can lose strength in the heat-affected zone after welding, not because the alloy is weak, but because the cold-worked temper locally relaxes. That is normal and accounted for in design allowables. What matters is that 5083 tends to retain excellent corrosion performance around welds when procedures are sound, weld filler is appropriate, and post-weld cleaning is treated as engineering, not cosmetics.

5059: when strength wants to move closer to the sea

5059 is a marine alloy that feels like 5083's more ambitious sibling. It is also Al-Mg based, but formulated to push higher strength levels while keeping marine corrosion behavior acceptable. In applications where weight is a ruthless constraint, or where you want additional margin in plate strength without leaving the Mg-family's corrosion comfort zone, 5059 is a compelling option.

You often see 5059 discussed for high-speed craft, naval structures, and demanding welded assemblies. It can deliver higher yield strength than 5083 in comparable tempers, which can translate into thinner plating, reduced weight aloft, or stronger panels at the same thickness. That said, the higher Mg content means you must stay disciplined about service temperature and sensitization risk. Long exposure to elevated temperatures can promote β-phase precipitation at grain boundaries in high-Mg alloys, reducing corrosion resistance. For most marine vessels operating in seawater temperatures, this is manageable, but it becomes more relevant near heat sources or in poorly ventilated compartments.

In purchasing, it is worth specifying tempers recognized for marine use, commonly H116 or H321 where applicable, and insisting on documentation that aligns with classification requirements if the structure is classed.

6082: the structural thinker for extrusions, machined parts, and stiffeners

6082 is not the first alloy people name when they say "marine plate," yet it is everywhere in marine structures because boats are not made only of hull plating. They are made of stiffeners, brackets, ladders, foundations, crane pedestals, and machined interfaces where dimensional stability matters. 6082, an Al-Mg-Si alloy, is heat-treatable and well suited to extrusions and structural components. In plate form, it is often chosen for parts that will be machined, bolted, or where higher stiffness and good bearing performance are valuable.

The typical temper is T6, meaning solution heat-treated and artificially aged. T6 gives 6082 strong, predictable mechanical properties, but the marine designer needs to remember two things. First, 6082's corrosion resistance in seawater is generally good, but it is not the same kind of "set-and-forget" behavior as 5xxx hull plate, especially in crevices and under deposits. Second, welding 6082 reduces strength in the heat-affected zone more dramatically than with non-heat-treatable alloys, unless post-weld heat treatment is feasible, which is uncommon for large marine fabrications. For welded hull shells, 6082 is rarely the first choice; for stiffeners, beams, and machined structures, it can be ideal.

Tempering and fabrication: where the alloy choice becomes real

Choosing between 5083, 5059, and 6082 is less about which datasheet looks best and more about how the plate will be processed. If the structure is dominated by long weld seams and exposure to seawater, 5083-H116/H321 and 5059 in similar marine tempers tend to be the natural candidates. If the structure relies on machining, bolted joints, or high dimensional precision, 6082-T6 brings the discipline of heat treatment to your tolerances and load paths.

Welding practice is the hinge point. For 5xxx alloys, filler metals like 5183, 5356, or 5556 are commonly selected depending on strength requirements and service conditions. For 6082, fillers like 4043 or 5356 may be used, but the choice affects cracking sensitivity, corrosion behavior, and strength. Implementation standards and class rules typically guide acceptable combinations, and a welding procedure qualification record is not paperwork-it is a map of what your structure will become after heat and restraint do their work.

Below is a practical reference table of typical composition limits. Always confirm with the applicable standard and mill certificate, as limits can vary slightly by standard and product form.

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) | Others (each/total) | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 5083 | ≤0.40 | ≤0.40 | ≤0.10 | 0.40–1.00 | 4.0–4.9 | 0.05–0.25 | ≤0.25 | ≤0.15 | ≤0.05/≤0.15 | Balance |

| 5059 | ≤0.10 | ≤0.40 | ≤0.10 | ≤0.50 | 5.0–6.0 | ≤0.30 | ≤0.40 | ≤0.15 | ≤0.05/≤0.15 | Balance |

| 6082 | 0.70–1.30 | ≤0.50 | ≤0.10 | 0.40–1.00 | 0.60–1.20 | ≤0.25 | ≤0.20 | ≤0.10 | ≤0.05/≤0.15 | Balance |

A selection mindset that saves refits later

A useful "unique" way to select these alloys is to imagine the vessel aging. Not at delivery, but after five years of dockings, repaint cycles, minor groundings, and hardware upgrades. Hull plating wants to stay corrosion-stable even when coatings are imperfect and weld seams have lived a full life; that is where 5083 and 5059 earn their reputation. Structural elements that are adjusted, drilled, or replaced during service want predictable machining and good stiffness; that is where 6082 often pays you back.

The best marine aluminium plate decision is the one that makes fabrication smoother, inspection simpler, and maintenance calmer. 5083 is the dependable narrator, 5059 is the performance upgrade when weight and strength are critical, and 6082 is the engineer behind the scenes keeping interfaces precise. When you cast them in the right roles, the vessel doesn't just float-it stays trustworthy, season after season, in the kind of water that is always looking for a weak point.

https://www.al-alloy.com/a/marine-aluminium-plate-5083-5059-6082.html