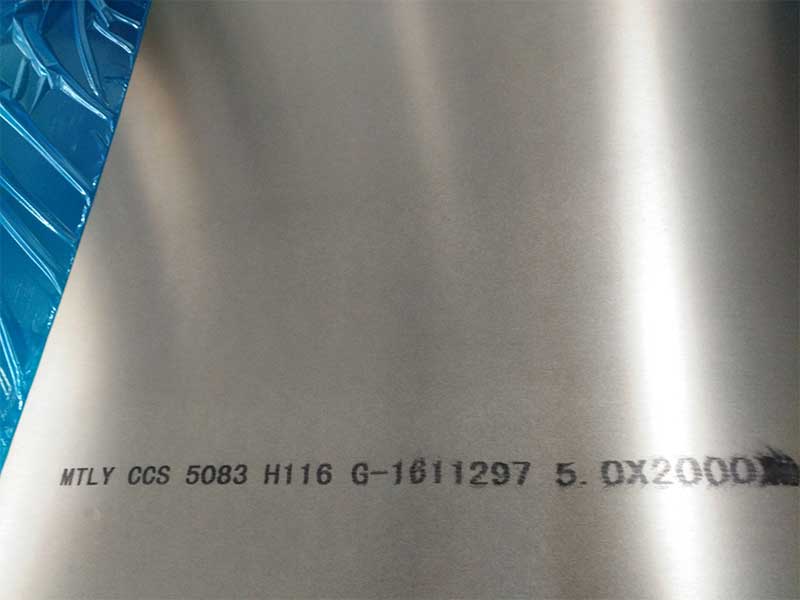

Marine Grade Aluminum Alloy Plate 5083 H111 H112 H116

When it comes to marine applications, where harsh saltwater environments and structural integrity cannot be compromised, Marine Grade Aluminum Alloy Plate 5083 is esteemed as a stalwart choice among engineers and designers. But within this widely-utilized alloy, certain tempers—H111, H112, and H116—offer a spectrum of options fine-tuned for durability, corrosion resistance, and mechanical strength. the distinct technical features and functional benefits of these tempers reveals why 5083 remains a trusted solution for seafarers and engineering projects alike.

What Is Marine Grade Aluminum Alloy 5083?

Aluminum Alloy 5083 is a non-heat-treatable alloy primarily alloyed with magnesium (~4.0–4.9%), along with manganese and traces of chromium, making it especially resistant to corrosion from seawater and excellent under extreme conditions. Its combination of lightweight nature with structural integrity presents massive weight savings crucial for marine vessels, floats, storage tanks, offshore platforms, and armor plating.

The Role of Tempering: Why H111, H112, and H116 Matter

The suffixes H111, H112, and H116 represent distinct temper conditions—factors influencing the mechanical properties due to work hardening, cold working, and natural aging. These temper classifications conform mainly to the ASTM (American Society for Testing and Materials) specifications such as ASTM B209, ASTM B928, and marine standards like ABS (American Bureau of Shipping), DNV (Det Norske Veritas), and Lloyd’s Register.

H111 Temper: Here, the alloy is strain-hardened to a degree less than fully hard flat rolled products but provides medium strength with excellent toughness—a versatile choice ideal for forming and welding applications where a softer state is preferred for shaping. Particularly suitable for hull plating sensitive to strain-induced stress.

H112 Temper: Recognized as a “commercially hard” temper, H112 delivers higher strength than H111 by increased work hardening. This temper is often selected where rigidity is prioritized over heavy forming, giving marine architects control over balances in structural frameworks.

H116 Temper: H116 is a variant engineered with additional strain hardening alongside thermal treatment to optimize corrosion resistance and high dynamic strength. It's predominantly utilized in marine applications that demand robust resistance to marine chloride pitting and higher fatigue strength — for durability in ship decks and offshore machinery foundations.

Technical Parameters of 5083 Marine Grade Aluminum Alloy Plate

| Characteristic | Value/Range | Unit |

|---|---|---|

| Alloy Composition | Magnesium (Mg) | 4.0 - 4.9 % |

| Manganese (Mn) | 0.4 - 1.0 % | |

| Chromium (Cr) | 0.05 - 0.25 % | |

| Density | 2.66 | g/cm³ |

| Yield Strength (H111) | ≥ 145 (approximate value) | MPa |

| Yield Strength (H112) | ≥ 215 (approximate value) | MPa |

| Yield Strength (H116) | ≥ 230 — slightly higher than H112 | MPa |

| Tensile Strength | 290 - 350 (depends on temper) | MPa |

| Elongation | 12 - 20 % (depending on temper and form) | % |

| Hardness (Brinell or HB) | 60 - 90 (approximate) | HB |

| Thermal Conductivity | 121 | W/(m·K) |

| Melting Point | 570 - 640 | °C |

Marine Grade Aluminum 5083 plates comply with:

- ASTM B209: Standard specification for aluminum and aluminum-alloy sheet and plate, outlining tensile strength, dimension tolerances, and surface finish criteria fundamental in marine industries.

- ABS/IMO: Classification societies’ standards to ensure the alloy performs in offshore and shipbuilding environments matching requirements regarding corrosion resistance, fatigue strength, and weldability.

Additional globally accepted standards include:

- EN AW-5083 in Europe (per EN 485)

- ISO 6361

Corrosion Resistance Enhancement: Alloy 5083’s magnesium creates stable, dense oxide layers resisting chlorides—complemented by tempering in H116 to boost protection under cyclic loading and corrosive assault.

Structural Reliability Under Dynamic Loads: H112 and H116 exhibit substantially improved yield and tensile strength which translate directly to reinforcement in boat hulls, bulkheads, ramps, and superstructures. This strength ensures safety without excessive reliance on thicker plating—favoring lightweight designs—a crucial factor in ship fuel economy.

Fabrication and Deployment Versatility: While H111 permits easier bending and shaping during fabrication, H116 is often the definitive select for components exposed to threats like cavitation erosion, stress corrosion cracking, or intense wave impacts.

Choosing the right Marine Grade Aluminum Alloy Plate 5083 temper boils down to a web of operational domains encompassing corrosion resistance, mechanical stress endurance, welding ease, and coating compatibility. The H111 temper hits a sweet spot for formability and durability early in the build phase, whereas H112 and H116 step up to meet rigorous strength and longevity criteria indispensable in tough maritime ecosystems.

Harnessing the nuanced differences within this seemingly singular alloy empowers engineers in naval architecture, shipyards, and offshore engineering firms to tailor design and manufacturing specifications down to microscopic levels—securing reliability launching one of humanity’s most challenging and critical frontiers: the sea.

For further inquiries or sourcing of precision Marine Grade Aluminum Alloy Plates 5083, consult expert suppliers familiar with temper classifications, guaranteed certifications, and custom machining services proven across demanding naval deployments.

https://www.al-alloy.com/a/marine-grade-aluminum-alloy-plate-5083-h111-h112-h116.html