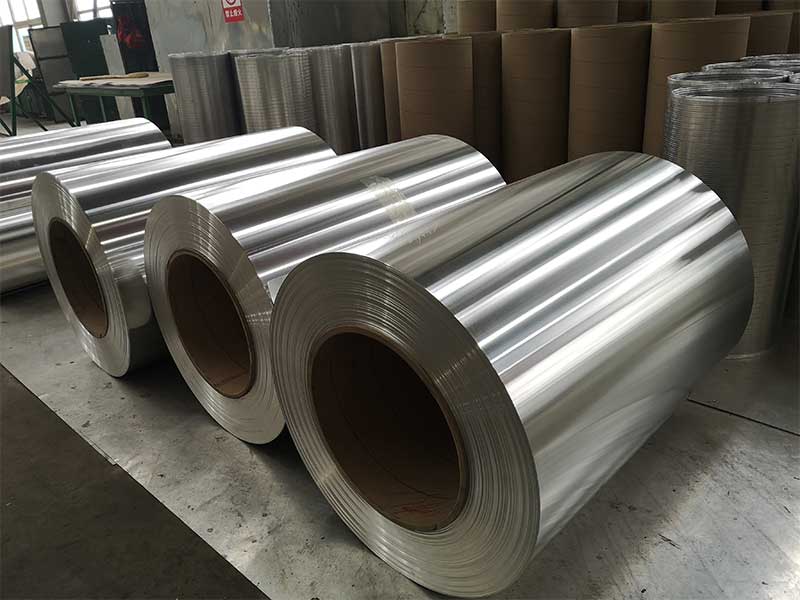

1050 1060 1070 1100 5005 5052 5083 6061 7075 aluminum coils

In the world of rolled metals, “aluminum coil” is a broad term. But when you narrow it down to specific alloys like 1050, 1060, 1070, 1100, 5005, 5052, 5083, 6061, and 7075, you’re no longer just buying a material—you’re choosing a performance package.

A practical way to understand these coils is to think of them as a continuum: from ultra-soft, ultra-pure conductivity materials to high-strength structural metals that can rival steel. Each alloy is engineered by adjusting just a few elements—mainly magnesium, manganese, copper, silicon, and zinc—but the result is a completely different behavior in forming, welding, anodizing, and corrosion resistance.

Below is a concise, application-focused guide that helps make sense of this family of alloys, along with typical parameters, tempers, and chemical compositions.

Pure and Near-Pure Series: 1050, 1060, 1070, 1100

These coils sit at the “purity” end of the spectrum. Their main function is not strength, but workability, conductivity, and clean surface.

Typical roles of these alloys

- 1050 / 1060 / 1070: electrical bus bars, transformer windings, capacitor shells, decorative strips, thermal shielding, lamp bases

- 1100: chemical and food equipment, nameplates, thin storage tanks, architectural trim, HVAC fins

functional traits

- Very high aluminum content (over 99% for 1050/1060/1070; 1100 has a small copper addition)

- Outstanding electrical and thermal conductivity

- Excellent deep drawing and spinning performance

- Non-heat-treatable; strength is achieved mainly by cold working (H tempers)

- Corrosion resistance is naturally high in most atmospheres

Typical tempers

- O (annealed): maximum formability, lowest strength

- H14 / H16 / H18: increasing strength with reduced formability

- H24 / H26: half-hard to three-quarter hard, often used for better rigidity in thin gauges

International implementation standards

- ASTM B209 (USA)

- EN 485 / EN 573 (Europe)

- GB/T 3880 (China)

For customers, the decision point is straightforward: when you need easy forming, clean anodized or mill finish, and high conductivity rather than high structural strength, these are the workhorse alloys.

Magnesium-Modified Non-Heat-Treatable Series: 5005, 5052, 5083

Moving up the spectrum, magnesium is added to aluminum to create real structural capability without sacrificing corrosion resistance. These 5xxx series coils are the backbone of marine, transportation, and architectural applications.

Typical roles

- 5005: architectural cladding, curtain walls, anodized fascia panels, interior decoration

- 5052: fuel tanks, truck bodies, marine panels, pressure vessels, toolbox and cabinet panels, refrigerator liners

- 5083: ship hulls, offshore platforms, cryogenic tanks, high-load marine and transport components

functional traits

- Magnesium additions from about 0.5% up to more than 4.0%

- Non-heat-treatable; strengthened by cold work and solid solution effects

- Excellent corrosion resistance, especially in marine and industrial environments

- Good weldability; 5083 in particular is a marine standard for welded structures

- 5005 is tailored for color-consistent anodizing, often used when 6061’s anodized appearance is too variable in façade work

Typical tempers

- H14 / H24: semi-hard for panels and general forming

- H32 / H34 / H36: balanced strength and formability for automotive and marine plates and coils

- O: for complex forming or deep drawing

- For 5083, tempers like H111, H116, H321 are commonly used for marine plates, though coils typically appear in softer H tempers for further processing

Implementation standards

- ASTM B209, B928 for marine grades

- EN 485, EN 573, EN 1386 (building applications)

- DNV, ABS, LR approvals for marine structure usage (primarily plate, but chemistry and properties follow the same philosophy in coil)

Functionally, 5005 positions itself as the “architectural anodizing” alloy, 5052 as the “general-purpose high-strength coil,” and 5083 as the “heavy-duty marine and cryogenic” solution.

Heat-Treatable Structural Alloys: 6061 and 7075

On the high-performance side, 6xxx and 7xxx coils deliver strength through heat treatment (solution treatment and artificial aging). These are the alloys for when hardness, rigidity, and fatigue resistance become critical.

Typical roles

- 6061: structural panels, lightweight frameworks, rail car components, high-load brackets, machined parts from coil-fed lines, bicycle components

- 7075: aerospace structural members, high-stress fastener stock, precision components, high-performance sports equipment where coil stock is slit and further processed

functional traits of 6061

- Alloyed mainly with magnesium and silicon (forming Mg2Si)

- Heat-treatable: can be supplied in T4, T6, T651, etc. (coils are usually T4 or T6-like after subsequent processing)

- Good balance of strength, weldability, and machinability

- Good corrosion resistance, but slightly lower than 5xxx marine alloys in severe saltwater conditions

functional traits of 7075

- High levels of zinc with magnesium and copper

- Extremely high strength, some tempers exceeding many steels on a strength-to-weight basis

- Not as corrosion-resistant as 5xxx or 6xxx; usually protected by coatings or cladding

- Limited weldability; typically mechanically fastened or adhesively bonded

- Common tempers for flat products: T6, T651, T73 (improved stress corrosion performance)

Implementation standards

- ASTM B209, B221, AMS specifications (aerospace)

- EN 485, EN 573 for 6xxx and 7xxx flat-rolled products

In coil form, 6061 is more widely used than 7075 because it balances formability, heat-treatability, and downstream processing compatibility.

Choosing by Function: How These Coils Map to Real Projects

Instead of seeing each alloy as an isolated code, it helps to map them to functional decision points:

- Need maximum conductivity and easy forming, with modest strength: choose 1050 / 1060 / 1070

- Need formable yet slightly stronger, with better chemical compatibility: choose 1100

- Need anodized architectural surfaces with uniform color: choose 5005

- Need strong, corrosion-resistant, weldable panels for tanks, vehicles, general marine: choose 5052

- Need high-load marine structure or cryogenic containment in coil/plate systems: choose 5083

- Need structural, machinable, heat-treatable coil for mechanical parts: choose 6061

- Need the highest strength for critical aerospace or performance applications, typically after slitting and further processing: choose 7075

This “function-first” approach prevents over-specifying (and overspending) on alloys that exceed the project’s real needs.

Representative Chemical Composition (Mass %)

Values below are typical ranges according to international standards; exact limits depend on specific standard and product form.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | – | ≤0.05 | ≤0.03 | ≥99.50 |

| 1060 | ≤0.25 | ≤0.35 | ≤0.05 | ≤0.03 | ≤0.03 | – | ≤0.05 | ≤0.03 | ≥99.60 |

| 1070 | ≤0.20 | ≤0.25 | ≤0.04 | ≤0.03 | ≤0.03 | – | ≤0.04 | ≤0.03 | ≥99.70 |

| 1100 | ≤0.95* | – | 0.05–0.20 | ≤0.05 | – | – | ≤0.10 | ≤0.05 | Remainder Al |

| 5005 | 0.30 | 0.70 | 0.05 | 0.20 | 0.50–1.1 | 0.10 | 0.25 | 0.05 | Remainder Al |

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2–2.8 | 0.15–0.35 | 0.10 | 0.15 | Remainder Al |

| 5083 | 0.40 | 0.40 | 0.10 | 0.40–1.0 | 4.0–4.9 | 0.05–0.25 | 0.25 | 0.15 | Remainder Al |

| 6061 | 0.40–0.80 | 0.70 | 0.15–0.40 | 0.15 | 0.80–1.2 | 0.04–0.35 | 0.25 | 0.15 | Remainder Al |

| 7075 | 0.40 | 0.50 | 1.2–2.0 | 0.30 | 2.1–2.9 | 0.18–0.28 | 5.1–6.1 | 0.20 | Remainder Al |

*For 1100, Si + Fe combined typically ≤0.95.

These controlled additions of magnesium, manganese, copper, silicon, and zinc are what transform soft, pure aluminum into tailored engineering materials.

Mechanical Parameters and Coil Supply Conditions

While exact mechanical properties (tensile strength, yield strength, elongation) vary by thickness and temper, typical ranges are:

- 1050/1060 in H14: tensile about 60–95 MPa, elongation 10–20%

- 5052 in H32: tensile about 215–265 MPa, good elongation for forming

- 5083 in H111: tensile about 270–350 MPa, excellent toughness

- 6061 in T6 (sheet/plate reference): tensile around 290–340 MPa

- 7075 in T6: tensile often 510–570 MPa

Common coil parameters supplied by manufacturers

- Thickness: about 0.2–8.0 mm depending on alloy and line capability

- Width: typically up to 2000 mm for wide coil, narrower for specialized lines

- Inner diameter: usually 508 mm or 610 mm

- Surface: mill finish, brushed, anodized-quality, or pre-painted (especially for 5005/5052 cladding)

From Code to Solution

For fast project decisions, it helps to translate alloy designations into a simple rule:

- 1xxx: conductivity and deep formability

- 5xxx: corrosion resistance and non-heat-treatable strength

- 6xxx: structural, heat-treatable, multipurpose

- 7xxx: maximum strength with controlled corrosion strategies

Once the function is clear—whether building façade, ship deck, refrigeration panel, precision machined part, or high-load structural member—the correct coil alloy, temper, and standard usually reveal themselves quickly.

1050 1060 1070 1100 5005 5052 5083 6061 7075

https://www.al-alloy.com/a/1050-1060-1070-1100-5005-5052-5083-6061-7075-aluminum-coils.html