0.7mm aluminum sheet alloy

0.7mm aluminum sheet alloy is a thin, lightweight, and formable sheet product widely used in roofing, cladding, automotive parts, electronics, and precision manufacturing. This thickness offers an excellent balance of strength, flexibility, and processability, making it ideal for both decorative and structural applications where low weight is critical.

Below is an in-depth look at its features, composition, performance, and typical use cases.

1. Product Profile

Product name: 0.7mm Aluminum Sheet Alloy

Typical alloys: 1050 / 1100 / 3003 / 3004 / 3105 / 5005 / 5052 (selected according to application)

Standard thickness: 0.70 ± tolerance (see table below)

Common tempers: H14, H16, H18, H24, H26, O (soft)

0.7mm aluminum sheet is often supplied in coil or flat sheet form. Customers choose the alloy and temper according to corrosion resistance, strength, and forming needs.

2. Features & Benefits

2.1 Main Features

- Lightweight:

Approx. 1.9 kg/m² at 0.7mm thickness, greatly reducing structural dead load. - High corrosion resistance:

Especially for 3xxx and 5xxx series alloys, suitable for outdoor and marine environments. - Good formability & bendability:

Even at 0.7mm, it can be easily sheared, bent, stamped, and roll-formed. - Attractive surface finish:

Available in mill finish, embossed, color-coated, or anodized surface. - Consistent flatness & thickness:

Produced on precision hot/cold rolling mills, suitable for automated processing lines. - Excellent recyclability:

100% recyclable with low energy cost compared to primary production.

2.2 Benefits for Customers

- Lower material consumption with sufficient strength at reduced thickness.

- Reduced transportation and installation costs due to low weight.

- Improved installation efficiency for roofing, wall cladding, and ceiling systems.

- Extended service life with proper alloy and coating selection.

- Enhanced design freedom (complex bending, profiling, perforations).

3. Typical Chemical Composition (Representative Alloys)

The exact alloy is selected based on application. Below are reference compositions for commonly used alloys in 0.7mm sheets.

3.1 1050 / 1100 (High-purity, general-purpose)

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Others (%) | Al (min, %) |

|---|---|---|---|---|---|---|---|---|

| 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.07 | ≤0.03 each | ≥99.50 |

| 1100 | ≤0.95* | – | 0.05–0.20 | ≤0.05 | – | ≤0.10 | ≤0.05 each | ≥99.00 |

*For 1100, Si+Fe ≤ 0.95%.

3.2 3003 / 3004 / 3105 (Mn-added, better strength & corrosion resistance)

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Others (%) | Al (bal.) |

|---|---|---|---|---|---|---|---|---|

| 3003 | ≤0.60 | ≤0.70 | 0.05–0.20 | 1.0–1.5 | – | ≤0.10 | ≤0.05 each | Remainder |

| 3004 | ≤0.30 | ≤0.70 | ≤0.25 | 1.0–1.5 | 0.8–1.3 | ≤0.25 | ≤0.05 each | Remainder |

| 3105 | ≤0.60 | ≤0.70 | 0.20–0.40 | 0.3–0.8 | 0.20–0.80 | ≤0.40 | ≤0.05 each | Remainder |

3.3 5005 / 5052 (Mg-added, high corrosion resistance, higher strength)

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Others (%) | Al (bal.) |

|---|---|---|---|---|---|---|---|---|---|

| 5005 | ≤0.30 | ≤0.70 | ≤0.20 | ≤0.20 | 0.50–1.1 | – | ≤0.25 | ≤0.05 each | Remainder |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | ≤0.05 each | Remainder |

4. Mechanical Properties & Performance

Mechanical properties vary by alloy and temper. The following values are typical reference ranges for 0.7mm sheets.

4.1 Mechanical Property Reference

| Alloy | Temper | Thickness (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation A50 (%) |

|---|---|---|---|---|---|

| 1050 | H14 | 0.7 | 100–145 | 60–95 | 5–10 |

| 1100 | H18 | 0.7 | 140–165 | ≥125 | ≥3 |

| 3003 | H14 | 0.7 | 145–185 | 115–145 | 5–8 |

| 3004 | H24 | 0.7 | 200–240 | 160–200 | 5–8 |

| 3105 | H16 | 0.7 | 170–215 | 130–180 | 3–8 |

| 5005 | H14 | 0.7 | 145–185 | 110–145 | 5–10 |

| 5052 | H32 | 0.7 | 215–265 | 160–200 | 5–10 |

4.2 Physical Properties

| Property | Typical Value (Al Alloys) |

|---|---|

| Density | ~2.70 g/cm³ |

| Melting range | 570–650 °C (depending on alloy) |

| Thermal conductivity | 130–230 W/m·K |

| Electrical conductivity | 28–60 % IACS (alloy-dependent) |

| Coefficient of thermal expansion | 23–24 × 10⁻⁶ /K |

5. Dimensional & Technical Specifications

5.1 Standard Size Range

| Item | Typical Range / Specification |

|---|---|

| Thickness | 0.70 mm nominal |

| Thickness tolerance | ±0.02–0.04 mm (depending on standard) |

| Width (coil/sheet) | 300–1600 mm |

| Coil inner diameter | 405 / 505 / 508 / 610 mm |

| Coil outer diameter | Max. 1800 mm (or as per order) |

| Coil weight | 1–6 tons (customizable) |

| Flat sheet length | 500–6000 mm (cut-to-length) |

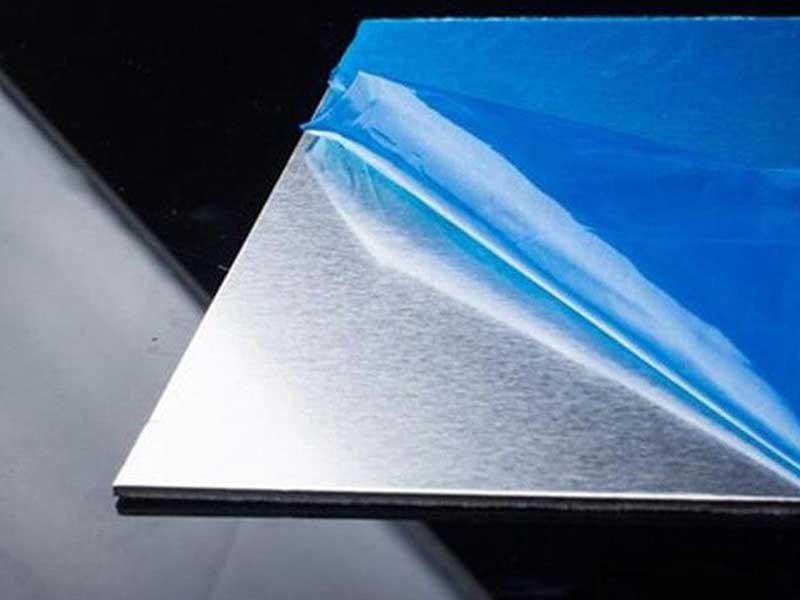

5.2 Surface & Coating Options

| Surface Type | Description & Use |

|---|---|

| Mill finish | Standard rolling finish, for general forming |

| Brushed / matte | Decorative, interior panels, appliances |

| Embossed | Stucco, orange peel, anti-slip patterns |

| Color-coated | Polyester (PE), PVDF, HDPE for cladding/roof |

| Anodized | Enhanced corrosion & aesthetics, electronics |

6. Processing & Fabrication Performance

6.1 Forming & Machining

| Process | Performance at 0.7mm | Notes |

|---|---|---|

| Shearing | Excellent | Low cutting force, clean edge possible |

| Bending | Very good | Min. bend radius typically ≥0.5–1.0 t* |

| Deep drawing | Good (1050, 1100, 3003) | For light housings, shells, trays |

| Punching | Very good | Suitable for perforated and louver panels |

| Roll forming | Excellent | Ideal for roofing and cladding profiles |

| Welding | Good (3xxx, 5xxx) | TIG/MIG; avoid high Cu content alloys if possible |

*t = sheet thickness.

6.2 Surface Treatment Compatibility

| Treatment | Suitability | Comment |

|---|---|---|

| Anodizing | Excellent (5005) | Uniform color, architectural quality |

| Powder coating | Excellent | Good adhesion on properly pretreated surface |

| Liquid painting | Excellent | Widely used in coil coating lines |

| Chemical conversion (chromate/Cr-free) | Excellent | For bonding/painting prep |

7. Major Application Fields

7.1 Building & Construction

0.7mm aluminum sheet is a mainstream thickness for:

- Roofing sheets and standing seam roofs

- Lightweight, reduces roof load.

- Good wind resistance when profiled.

- Wall cladding and facade systems

- Used as single-skin sheets or laminated with insulation.

- Often in color-coated 3004/3105/5005.

- Ceiling panels & soffits

- Easy installation, many surface designs.

- Rainwater systems (gutters, downpipes, cappings)

- Requires corrosion-resistant 3xxx/5xxx series.

7.2 Transportation & Automotive

- Body panels for caravans, trailers, vans

- 5052/3003 for side panels, roofs.

- Interior trim and partition panels

- Decorative coatings and easy forming.

- Heat shields and covers

- Thin gauge, good heat reflection.

7.3 Electrical & Electronics

- Cable trays, ducts, and shielding covers.

- Instrument housings and small chassis.

- LED lamp backplates, light box panels (often whitened or reflective coated).

7.4 Consumer Goods & Industrial Products

- Appliance panels (refrigerators, air conditioners, ovens – with suitable coatings).

- Packaging & cases for tools, instruments, and displays.

- Nameplates, signage boards, advertising panels (often pre-painted or anodized).

8. Selection Guide: How to Choose the Right 0.7mm Alloy

| Application Requirement | Recommended Alloy/Temper | Reason |

|---|---|---|

| Standard interior panel, cost focus | 1050/1100 H14/H18 | Low cost, adequate strength |

| General roofing & wall cladding | 3003 / 3004 / 3105 H24/H26 | Better strength & corrosion resistance |

| Architectural anodized facade | 5005 H14/H24 (anodizing quality) | Uniform anodized color, good durability |

| Marine / high-corrosion environment | 5052 H32 | High Mg for excellent corrosion resistance |

| Deep-drawn housings, light forming | 1050 / 1100 / 3003 O/H12 | High ductility |

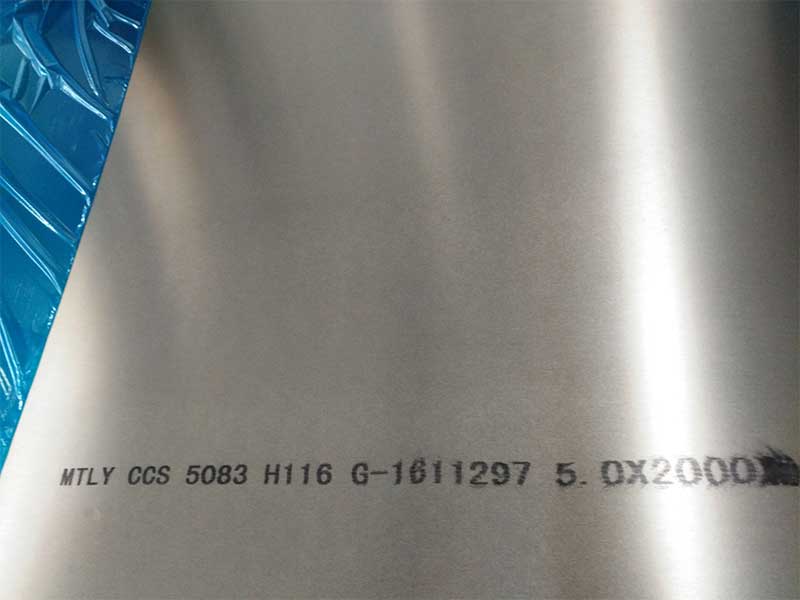

9. Quality Control & Standards

0.7mm aluminum sheets are typically produced and inspected in accordance with major international standards, such as:

| Standard | Scope |

|---|---|

| EN 485 / EN 573 | Wrought aluminum products & composition |

| ASTM B209 | Aluminum and aluminum-alloy sheet and plate |

| GB/T 3880 | Chinese standard for sheet/strip |

inspection items:

- Chemical composition – spectrometer analysis per heat batch.

- Mechanical properties – tensile tests, elongation.

- Thickness & width tolerance – online gauge and lab checks.

- Flatness, edge quality, and surface defects – visual and dimensional inspection.

- Coating thickness & adhesion (for coated products).

0.7mm aluminum sheet alloy combines low weight, moderate strength, and excellent formability, making it an ideal choice for:

- Roofing, cladding, ceilings, and rainwater systems

- Vehicle body panels and interior trims

- Electrical housings and cable management

- Decorative panels, signage, and appliance skins

By properly selecting the alloy (1xxx, 3xxx, or 5xxx series), temper, and surface finish, customers can achieve an optimal balance of cost, durability, and aesthetics. The use of standardized, tightly controlled 0.7mm sheets also ensures stable processing on high-speed lines and consistent performance in service.