Thickness of aluminum plate

When people talk about aluminum plate, they usually jump straight to alloy grades—6061, 5083, 7075—or to surface treatments and corrosion resistance. Thickness tends to be treated like a simple dimension, a number you look up in a catalog and move on from. In practice, thickness is not just a physical measure; it is a design variable that quietly governs strength, weight, manufacturability, cost, and even how an alloy behaves at the microscopic level.

From an engineer’s or fabricator’s perspective, “how thick?” is rarely a trivial question.

Thickness as a Negotiation Between Strength and Weight

Think of aluminum plate thickness as the result of a negotiation between competing priorities.

A marine engineer wants enough thickness in a 5083-H116 hull plate to resist wave impact and local buckling, but every extra millimeter adds weight that increases fuel consumption. An aerospace designer using 2024-T351 or 7075-T651 plate is obsessed with stiffness-to-weight ratios; shaving off half a millimeter across a large wing skin can translate to hundreds of kilograms saved on a fleet of aircraft.

The paradox with aluminum plate is that we often choose a particular alloy for its high strength, only to need less thickness than a lower-strength alloy would require. This allows us to drop weight and sometimes even reduces overall material cost despite a higher per‑kilogram price.

For example, a general comparison:

- A structural panel in 5083-H111 might need a thickness of 12 mm to meet a specific load and stiffness requirement.

- Switching to 6061-T651, with higher yield strength and good modulus, might allow that same panel to function safely at 8–10 mm.

- In very weight-sensitive designs, a high-strength alloy such as 7075-T651 could bring that thickness down further, though with trade-offs in corrosion resistance and weldability.

Thickness is the point where mechanical properties, safety factors, and mass converge.

The Manufacturing View: Thickness as a Process Constraint

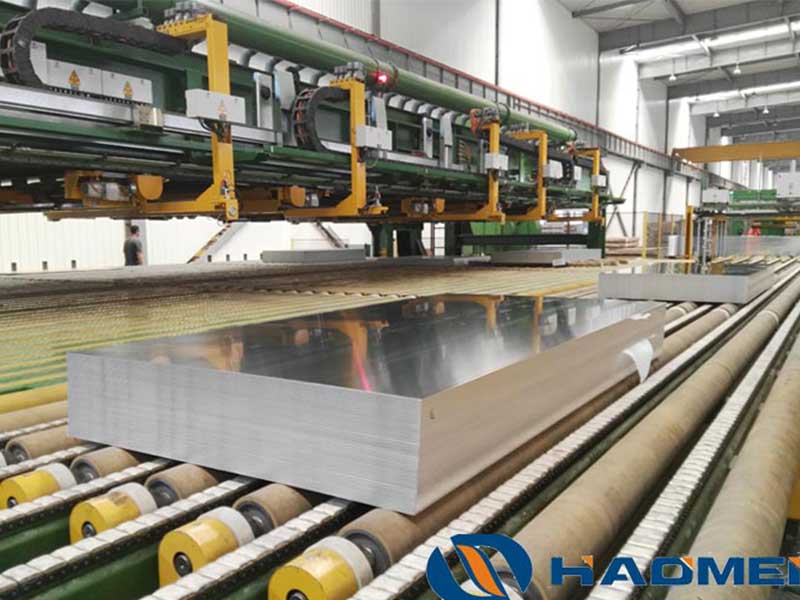

From a rolling mill’s viewpoint, the thickness of aluminum plate is a process capability story more than a design story.

Aluminum plate begins life as a cast slab, typically 400–600 mm thick. That slab is hot rolled repeatedly until the desired thickness is achieved. As thickness goes down, constraints go up:

- Very thick plate (above roughly 100–150 mm) pushes the limits of heat treatment uniformity. Achieving full and consistent temper through the thickness is more difficult.

- Medium plate (around 6–50 mm) is the sweet spot for many structural applications—easy to roll, heat-treat, machine, and test.

- Thin plate approaching sheet gauge (below about 4–6 mm) introduces demands on flatness and residual stress control. Thin plate warps easier and responds more dramatically to machining and welding.

Plate thickness also governs how tempering is implemented. Take two common alloys:

- 6061-T651 plate is solution heat-treated, quenched, stress-relieved by stretching, and then artificially aged. Stretching thick plate requires heavy equipment, and there are practical limits on maximum thickness that can be reliably stress-relieved in this way.

- 5083-H116 marine plate is strain-hardened and stabilized. Its mechanical properties are heavily influenced by the cold working during rolling. The final thickness determines how much cold work can be distributed through the cross-section without excessive internal stress or distortion.

Standard product ranges reflect these process realities. Typical rolled plate thicknesses might run from about 6 mm up to 150 mm, with some mills capable of thicker sections. Below about 6 mm, material is often classified and supplied as sheet rather than plate, using different production lines and standards.

Thickness is also a legal and contractual value. International standards define not only dimensional tolerances but also which property requirements apply at which thickness ranges.

A few examples:

- ASTM B209 specifies requirements for aluminum and aluminum-alloy sheet and plate, with tolerances that change with both alloy and thickness. Thicker plates allow wider deviations in flatness and thickness than thin plates.

- EN 485 series and EN 573 (for European markets) similarly treat thickness as a categorical factor when defining permissible variations, mechanical property test positions, and delivery conditions.

- Marine and pressure vessel codes (such as DNV, ABS, ASME) often introduce additional demands—like ultrasonic testing or tighter flatness—once thickness exceeds a certain threshold, because the consequences of defects scale with section thickness.

In pressure vessels and cryogenic tanks made from alloys such as 5083 or 5454, plate thicker than a certain value may require through-thickness toughness testing. A micro-shrinkage that is harmless in a 6 mm wall can become a critical stress raiser at 50 mm.

So choosing thickness is not only about what the component “needs” mechanically, but also about which standards it will fall under, which inspections will be mandatory, and what documentation the supplier must deliver.

Microstructure, Residual Stress, and the Inside Story of Thickness

What happens inside an aluminum plate as it gets thicker is often ignored, but it drives performance in subtle ways.

In a thin 6061 plate, solution heat treatment and quenching can reach through the entire thickness quite uniformly. Cooling rates are consistent enough that precipitation hardening is well controlled during subsequent aging. In a thick 150 mm 6082-T651 plate, the mid-thickness region cools much more slowly, potentially leading to:

- Slightly lower yield strength at mid-thickness than near the surfaces.

- Variations in precipitate size and distribution through the thickness.

- Residual stress patterns that differ across the cross-section.

This is one reason why mechanical properties in standards are often qualified by thickness. A datasheet might say:

- 6061-T651 plate, typical thickness 10–60 mm: yield strength ≥ 275 MPa, tensile strength ≥ 310 MPa, elongation ≥ 8%.

- At larger thicknesses, the guaranteed minimum yield and tensile strengths may be slightly reduced.

From the machining and welding side, residual stress in thicker plate can be an invisible adversary. A part milled out of 80 mm plate may “move” several tenths of a millimeter as material is removed, even if the plate left the mill flat. Proper stress-relieved tempers (such as -T651, -T652) and thoughtful roughing/finishing strategies become more important as thickness increases.

When Thickness Is the Enemy: Forming and Joining

Aluminum is relatively soft compared with steel, but plate thickness determines whether it will cooperate or fight back during forming and joining.

Thicker plate:

- Demands larger bend radii to avoid cracking, especially in age-hardened tempers like 6061-T6 or 7075-T6.

- Requires more powerful presses and tools for cold forming.

- In welding, accumulates more heat and often needs higher heat input, careful preheat, and tightly controlled interpass temperatures. Thermal gradients are steeper, so residual distortions and local softening around the weld can be more pronounced.

This is one reason marine designs in 5xxx alloys for hulls and decks often intentionally use relatively modest thicknesses, repeating structural patterns (stiffeners and frames) rather than jumping to very thick plate. The structure is lighter, easier to weld, and more forgiving during fabrication.

Thickness and Corrosion: Not Just a Lifetime Issue

For corrosion, thickness is often viewed as a time buffer: more metal means more sacrificial material before perforation. That is true, but the alloy and temper decide whether thickness is even the right defense.

Alloys such as 5083-H116 and 5456-H116 are specifically processed and tempered to maximize resistance to intergranular and exfoliation corrosion in marine environments. The temper and chemistry control grain structure and precipitate distribution. Whether the plate is 8 mm or 20 mm thick, the surface region that interacts with seawater looks very similar.

By contrast, high-strength copper-bearing alloys such as 2024 and 7075, especially in peak-hardening tempers like T6, are more vulnerable to localized forms of corrosion. Thicker sections can amplify the effects of corrosion fatigue and stress corrosion cracking because high internal stresses are often locked into thick plates and forgings. In such cases, no practical thickness is “safe” without appropriate design detail, surface protection, and stress control.

A Snapshot: Thickness, Alloy, and Properties

Below is a simplified view of how thickness intersects with alloy choice and mechanical properties. These values are indicative, not guaranteed, and based on typical plate ranges:

| Alloy & Temper | Typical Plate Thickness Range (mm) | Yield Strength (MPa) | Tensile Strength (MPa) | Typical Uses |

|---|---|---|---|---|

| 1050A-H14 | 0.5–20 | 60–80 | 100–120 | Chemical equipment, reflectors |

| 5052-H32 | 0.8–25 | 160–200 | 210–260 | Enclosures, sheet metal work |

| 5083-H116 | 3–60 | 215–240 | 305–340 | Marine hulls, cryogenic tanks |

| 5754-H114 | 2–50 | 130–180 | 220–270 | Automotive panels, marine components |

| 6061-T651 | 6–150 | 240–280 | 260–320 | General structures, tooling |

| 6082-T651 | 8–200+ | 260–310 | 300–340 | Heavy structures, bridges |

| 2024-T351 | 8–150 | 300–340 | 430–470 | Aerospace structural plate |

| 7075-T651 | 8–150 | 430–480 | 520–580 | High-strength aerospace & tooling |

Notice that for many alloys, the published property ranges assume a certain thickness band. Outside those ranges, properties can shift, and standards may specify different minimum values.

Thinking in Thickness Layers, Not Just Millimeters

The most productive way to think about aluminum plate thickness is to treat it as a system parameter, not a static dimension. Every time thickness changes, several things shift at once:

- The stress and stiffness behavior of the component.

- The rolling, heat treatment, and tempering strategies available.

- Applicable standards, tolerances, and test obligations.

- Ease of forming, welding, and machining.

- Internal residual stress patterns and microstructural uniformity.

- Corrosion behavior over time and under load.

A design that merely “meets strength” at a given thickness may be heavy, difficult to fabricate, or non-compliant with a standard. A more refined design looks at thickness as a tuning knob: adjusting it together with alloy, temper, and processing route to land in a narrow band where manufacturing is stable, quality is high, and performance over the service life is genuinely optimized.

In that sense, the thickness of aluminum plate is less a measurement on a drawing and more a quiet, decisive argument among physics, metallurgy, and practicality. When they reach consensus, the chosen thickness rarely looks accidental.