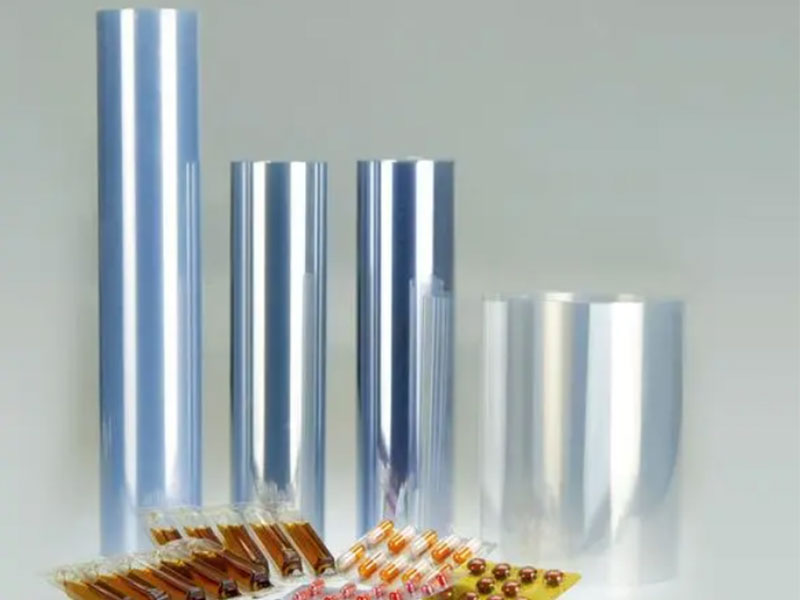

Pharmaceutical Use Aluminum Foil Blister Foil

Pharmaceutical use aluminum foil blister foil is a critical primary packaging material for solid dosage forms such as tablets, capsules, and lozenges. It provides a robust barrier against moisture, oxygen, light, and contaminants, ensuring drug stability throughout shelf life and distribution.

Modern blister foils combine carefully selected aluminum alloys, precise tempering, and tailor‑made coatings or heat‑seal lacquers that bond securely to PVC, PVdC, PP, or other blister base webs. This balance of barrier performance, machinability, and patient convenience makes aluminum blister foil a preferred solution for regulated pharmaceutical markets worldwide.

Features & Benefits

- Excellent moisture, oxygen, and light barrier for sensitive formulations

- Heat‑sealable to common blister base films (PVC, PVdC, ACLAR, PP, PET)

- Consistent peel or push‑through opening characteristics

- Available in printed, unprinted, or lacquer‑coated forms

- Compatible with high‑speed blister packaging lines

- Compliance with major pharmacopeia and food‑contact regulations

- Good formability, flatness, and slit‑edge quality for accurate indexing

Typical Applications

Solid oral dosage forms

- Tablets (coated, uncoated, effervescent)

- Hard and soft gelatin capsules

- Caplets and lozenges

Hospital and retail pharma packaging

- Unit‑dose packs for hospitals and clinics

- Compliance packs for chronic‑therapy medication

- Sample packs and promotional blisters

Special formulations

- Moisture‑sensitive APIs (e.g., antibiotics, proton pump inhibitors)

- Light‑sensitive drugs (e.g., some vitamins, hormones)

- Products requiring child‑resistant or senior‑friendly opening designs

Alloy & Temper Options

Pharmaceutical blister foil is most commonly produced from high‑purity aluminum alloys such as 8011, 8021, and 8079 in soft or hard tempers. Alloy and temper selection affects mechanical strength, formability, and barrier performance.

Common Alloy & Temper Selection

| Parameter | Option A | Option B | Option C |

|---|---|---|---|

| Alloy | 8011 | 8021 | 8079 |

| Temper | O (Soft) | H18 (Hard) | H14 / H16 |

| Typical Use | Push‑through, cold‑form backing | High‑barrier lidding | High ductility lidding |

| Strength vs. Flexibility | High flexibility | High strength | Balanced |

| Barrier Performance | Very good | Excellent | Excellent |

Chemical Composition (Typical Range)

Values below are indicative for pharmaceutical‑grade 8011 and 8021 alloys. Exact composition is controlled within narrow limits based on standards and customer specifications.

Example – Alloy 8011

| Element | Typical Range (wt%) |

|---|---|

| Al | Balance |

| Si | 0.40 – 0.80 |

| Fe | 0.60 – 1.00 |

| Cu | ≤ 0.10 |

| Mn | ≤ 0.20 |

| Mg | ≤ 0.05 |

| Zn | ≤ 0.10 |

| Ti | ≤ 0.08 |

| Others | ≤ 0.05 each, ≤ 0.15 total |

Example – Alloy 8021

| Element | Typical Range (wt%) |

|---|---|

| Al | Balance |

| Si | ≤ 0.20 |

| Fe | 1.10 – 1.60 |

| Cu | ≤ 0.05 |

| Mn | ≤ 0.10 |

| Zn | ≤ 0.10 |

| Ti | ≤ 0.08 |

| Others | ≤ 0.05 each, ≤ 0.15 total |

Standard Technical Specifications

Dimensional & Surface Data

| Parameter | Typical Range / Option |

|---|---|

| Foil thickness | 18 – 30 μm (common: 20, 25 μm) |

| Width | 200 – 1200 mm (custom slit widths available) |

| ID of core | 76 mm or 152 mm |

| Coil outer diameter | Up to 600 mm (or per line requirement) |

| Surface finish | One side matte / one side bright |

| Surface tension | ≥ 32–38 dynes/cm (pre‑treated) |

| Lubricant | Food‑grade, very low residuals |

Mechanical Properties

| Property | Typical Value (H18 temper, 25 μm) | Test Direction / Notes |

|---|---|---|

| Tensile strength | 120 – 150 MPa | Longitudinal |

| Elongation | ≥ 2 – 4 % | Longitudinal |

| Yield strength | 100 – 130 MPa | Approximate |

| Pinholes (≥ 0.5 mm) | 0 per m² | Visual & light table inspection |

| Pinholes (≥ 0.3 mm) | ≤ 1 per m² | |

| Density | ~ 2.71 g/cm³ | Aluminum typical |

Barrier Performance (Indicative)

Barrier performance is controlled by alloy purity, thickness, and coating integrity.

| Parameter | Typical Performance* |

|---|---|

| Water vapor transmission rate | ~ 0 g/m²·day (foil itself) |

| Oxygen transmission rate | ~ 0 cc/m²·day (foil itself) |

| Light transmission | Opaque, total light barrier |

| Micro‑perforations | None (100% pinhole tested) |

*Values refer to bare foil; complete blister performance depends on laminate structure and base web.

Coatings, Lacquers & Printing

Blister foil surfaces are usually coated and/or printed to enable reliable sealing and brand presentation.

Heat‑Seal & Primer Systems

| Layer | Typical Material / Property |

|---|---|

| Heat‑seal lacquer | PVC, PVdC, PP or universal seal types |

| Coating weight (dry) | 4 – 7 g/m² (customizable) |

| Sealing temperature | 180 – 230 °C (line‑dependent) |

| Sealing pressure | 3 – 7 bar (typical blister machines) |

| Sealing time | 0.4 – 1.0 s (short dwell for high output) |

| Adhesion to foil | Excellent, no delamination under peel/push tests |

Printing & Appearance

| Feature | Specification Options |

|---|---|

| Printing method | Gravure or flexographic |

| Colors | 1–8 colors, Pantone or custom shades |

| Side printed | Non‑sealing side (customer logo, text, codes) |

| Registration accuracy | Tight tolerances for perforation alignment |

| Inks | Low‑migration, pharma‑grade, heat‑resistant |

Compatibility with Blister Base Webs

Pharmaceutical blister foil must seal efficiently to different base webs while preserving easy opening for patients.

| Base Web Material | Typical Seal System | Benefits |

|---|---|---|

| Rigid PVC | PVC‑specific lacquer | Cost‑effective, widely used |

| PVC/PVdC | PVC‑specific lacquer | Enhanced moisture barrier |

| PVC/ACLAR | PVC or universal lacquer | Excellent moisture and gas barrier |

| PP | PP‑specific lacquer | PVC‑free solution, high heat resistance |

| PET | Special primer / lacquer | High clarity base, strong mechanical strength |

| Cold‑form foil | Direct aluminum‑aluminum | Maximum barrier (Al/Al blisters) |

Regulatory & Quality Aspects

Pharmaceutical blister foils are manufactured under stringent quality and hygiene conditions. compliance and quality elements typically include:

- Conformance to applicable pharmacopeia and food‑contact regulations (e.g. EU, FDA‑related frameworks)

- Production under ISO‑style quality management systems

- Good Manufacturing Practice (GMP) principles for primary pharma packaging

- Migration and extractables testing of coatings, lacquers, and inks

- Batch traceability from melt to final slit roll

Typical quality controls cover alloy composition, mechanical properties, thickness tolerance, surface cleanliness, pinhole rate, coating weight, sealability, and print quality.

Packaging, Storage & Handling

Packaging

| Aspect | Typical Practice |

|---|---|

| Roll protection | Polyethylene wrap, end discs, edge protectors |

| Outer packing | Strong corrugated cartons or wooden cases |

| Labeling | Product code, alloy, temper, thickness, lot no. |

| Desiccant use | Optional, per customer requirement |

Storage Conditions

| Parameter | Recommended Condition |

|---|---|

| Temperature | 15 – 30 °C |

| Relative RH | 35 – 65 % |

| Environment | Clean, dry, free of corrosive vapors |

| Shelf life | Typically up to 1–2 years if sealed |

Foils should be acclimatized to the packaging hall conditions before use to minimize condensation and ensure optimal sealing performance.

Why Choose Our Pharmaceutical Blister Foil

- Stable alloy sourcing and strictly controlled melting and casting

- Tight thickness tolerances for uniform sealing and forming behavior

- Clean, low‑pinhole surface meeting demanding barrier requirements

- Tailored heat‑seal lacquers compatible with your existing blister lines

- Flexible customization of width, core, printing, and packaging

With the right combination of alloy, temper, coating, and converting control, pharmaceutical use aluminum foil blister foil provides a reliable, regulatory‑compliant packaging solution that protects your products and supports patient safety from the filling line to the point of use.

https://www.al-alloy.com/a/pharmaceutical-use-aluminum-foil-blister-foil.html